Flammable Refrigerants Gas Pressure Test Bench For Compression - type Appliances

Flammable Refrigerants Gas Pressure Test Bench For Compression - type Appliances

- Model:

Flammable Refrigerants Gas Pressure Test Bench For Compression - type Appliances

IEC 60335-2-24 clause 22.7 Gas Pressure Test Bench For Compression-type Appliances Using Flammable Refrigerants

Standard: IEC 60335-2-24 clause 22.7.

Features:

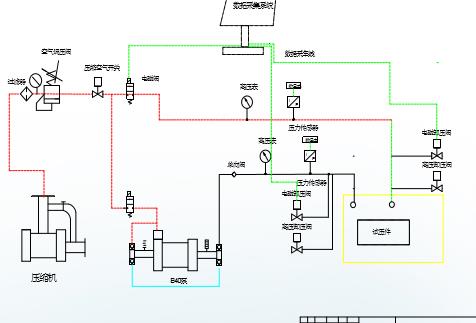

This computer control air seal pressure test device, can complete the low and high pressure testing. Computer smart system detect and acquisition high pressure and low pressure value respectly, and can control the pressure on low pressure end and high pressure end respectly.

Core booster equipment adopt smart pressure control system, can adjust and control output pressure freely.

Advanced technology, reasonable structure design, with small size, light weight, beautiful appearance features.

All pressure parts using international brand standard parts, no welding connection, easy disassembly, high security, long lifespan, easy maintenance.

The device is driven by compressed air, use of high-quality high-pressure pump, the low pressure and high pressure detecting can be completed at the same time.

Equipped with low pressure compressor and B10 high pressure booster pump, can realize the whole pressure range test and control.

Test pressure range 0~3Mpa, select required pressure according to actual test requirement.

Computer system can set and control test pressure, real time displaying pressure curve. Can print test report when test completed.

When test pressure reached, automatic stop pressurization and entering pressure maintaining and start timing device.

Smart pressure control system, can complete the real-time pressure acquisition, and data analysis and recording.

Pressure maintaining period, test system automatic timing, alarm when maintaining period complete.

Test procedure programmable, reach test pressure automatic stop pressurization.

When test completed, can print CN-EN test report, same test data in excel form.

| Principle | According to the different pressure of test sample, smart test system complete the running, air detection and related pressure detection work. | |

| Introduction | Test pressure | 0~3Mpa, adjustable |

| Control accuracy | Upper limit: +3%; Lower limited: -1% | |

| Test medium | Compressed air | |

| Pressure control | System control or manual control | |

| Operation | System control or manual control | |

| Sample qty | 1 channel, control test pressure and test time | |

| Sample installation | Connection | |

| Composition | Circulating system, pressure control system, workpiece mounting device, manual control device | |

| Application | Pressure detection, sealing test | |

Specifications

| Test medium | Compressed air |

| Test pressure | 0~3Mpa |

| Pressurize flow | 86L/min |

| Driving pressure | 0.3~0.8Mpa |

| Driving flow | 0.3~1CBM/min |

| Time display | Computer display |

| Pressure curve display | Data acquisition software real time display, can zoom in and out |

| Report print | Test report can be printed and test data can be saved |

| Test data storage | Can save reports and excel form, the data collected each time can be saved |

| Display accuracy | 0.1Mpa |

| Control accuracy | 0.5% |

Schematic diagram