Products

28.3 L/Min Medical Material Tester Bacterial Filtration Efficiency (BFE) Test Chamber

Products Description

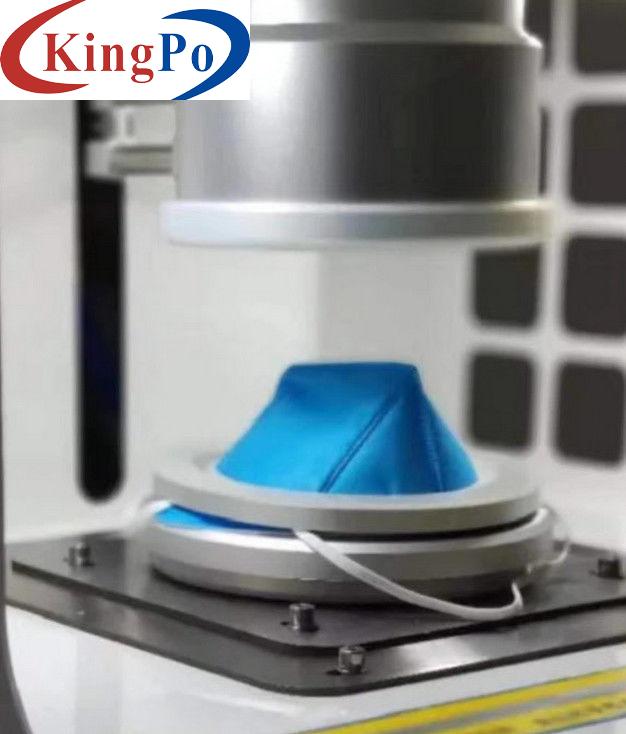

Face Mask Bacterial Filtration Efficiency (BFE) Test Chamber

Facial Mask Tester Bacterial Filtration Efficiency (BFE) Test Chamber 28.3 L/Min Sampling Flow

Product overview:

The main performance indicators of the mask bacterial filtration efficiency (BFE) tester not only meet the requirements of B.1.1.1 of YY0469-2011 Annex B bacterial filtration efficiency (BFE) test method, but also comply with the requirements stipulated in American ASTM 2100, ASTMF2101 and European EN14683 standards. Innovative improvements have been made on this basis. The simultaneous sampling method with dual gas channels has been used to improve the accuracy of sampling. It is suitable for the measurement and verification departments, scientific research institutes, mask manufacturing enterprises and other relevant departments to measure the filtering efficiency of mask bacteria.

Equipment Features:

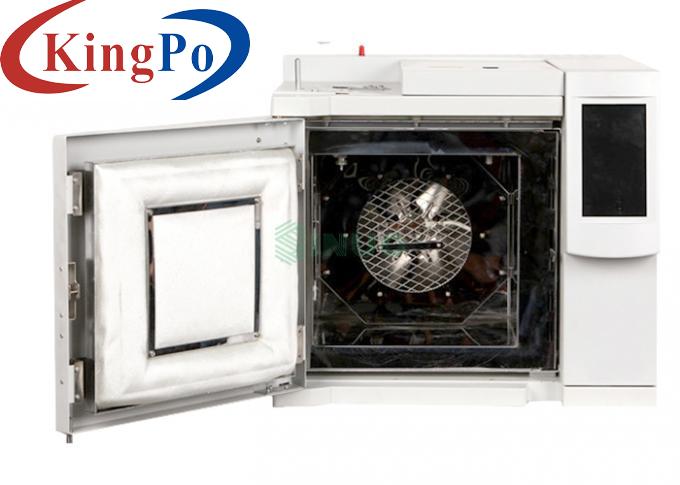

2. Built-in peristaltic pump in negative pressure cabinet, A / B two-way six-stage Andrsen sampler

3. Flow rate of peristaltic pump can be set

4. The spray flow rate of bacteria liquid of special microbial aerosol generator can be set

5. Good atomization effect

6. Embedded high-speed industrial microcomputer control

7. 10.4 inch industrial-grade high-brightness color touch screen

8. USB interface, support U disk data transfer

9. Built-in high-brightness lighting lamp

10. Built-in leakage protection switch to protect the safety of operators

11. The inner layer of stainless steel is integrally processed and formed, and the outer layer is sprayed with cold-rolled sheet

12. Insulation between inner and outer layers, flame retardant

13. Front opening and closing glass door, convenient for laboratory personnel to observe and operate

14. Removable bracket with adjustable bracket height

15. Support, mobile dual-use casters

Main Parameters

Range

Resolution

Max. Allowed Error

Sample flow rate of channel A

28.3 L/min

0.1 L/min

Better than ±2.5%

Sample flow rate of channel B

28.3 L/min

0.1 L/min

Better than ±2.5%

Spray Flow

(8~10)L/min

0.1 L/min

Better than ±2.5%

Peristaltic Pump Flow

(0.006~3.0)mL/min

0.001 ml/min

Better than ±2.5%

Front Pressure in of Flowmeter A

(-20~0)kPa

0.01kPa

Better than ±2.5%

Front Pressure in of Flowmeter B

(-20~0)kPa

0.01kPa

Better than ±2.5%

Front Pressure of Spray Flowmeter

(0~300)kPa

0.1kPa

Better than ±2.5%

Aerosol Negative Pressure

(-90~-120)Pa

0.1Pa

Better than ±2.5%

Working Temperature

(0~50)℃

Cabinet Negative Pressure

(-50~-200)Pa

Data Storage Capacity

>10000 groups

High Efficiency Air Filter Characteristics

Filtration efficiency for particles above 0.3um ≥99.99%

Aerosol Generator Mass Median Diameter

Average particle diameter (3.0 ± 0.3) um, geometric standard deviation≤1.5

Two-way 6-level Anderson Sampler Captures Particle Size

Ⅰlevel>7um, Ⅱ level (4.7~7) um,Ⅲ level (3.3~4.7) um,Ⅳ level(2.1~3.3)um,Ⅴ level(1.1~2.1)um, Ⅵ level(0.6~1.1)um

Aerosol Chamber Specifications

(Length 600 * diameter 85 * thickness 3) mm

Total Number of Positive Quality Control Sampler Particles

(2200±500)cfu

Ventilation Flow of Negative Pressure Cabinet

≥5m³/min

Negative Pressure Door Size

(Length 1000 * width 730) mm

Equipment Size

(Length 1180 * Width 650 * Height 1300) mm

Bracket Size

(Length 1180 * Width 650 * Height 600) mm, height adjustable within 100mm

Working Power Supply

AC 220V±10%, 50Hz

Equipment Noise

<65dB(A)

Equipment Weight

Approx. 150kg

Equipment Power

<1500W