Products

IEC 60320-1 Clause 8.8 Abrasion Resistance Test Machine Stickers Label Ink Rub Tester

Products Description

IEC 60320-1 Clause 8.8 Abrasion Resistance Test Machine Stickers Label Ink Rub Tester

Standards:

This label marking abrasion test apparatus conforms to IEC60320-1 clause 8.8, IEC 60335-1 clause 7.14, IEC 60065:2014 clause 5.1, IEC 60950:2013 clause 1.7.11, IEC 60669-1 clause 8.9.

Product Information:

Samples and restrictions: Markings of household and similar electrical appliances, household plugs and sockets, and couplings.

Technical parameters:

1. Comes standard with multiple pieces of cotton cloth, an eraser, and two pencils

Maintenance Notes:

1 The instrument must be placed on a stable surface before use.

2 It is not allowed to move the machine during use.

3 Select the appropriate power supply voltage, should not be too high, to avoid burning the instrument.

4 If the instrument works abnormal, please contact with us for timely processing.

5 The instrument must be used in a good ventilation environment.

6 Please add lubricating oil to the mechanical transmission part in time due to the large operating load of each component of the button mechanism.

7 After each test is completed, operator should clean the machine.

8 The control box part must be wiped with a dry cloth.

Troubleshooting:

1 If the POWER is turned on, the instrument is not powered on or the power indicator is not light: if the power indicator is damaged, replace the indicator; if there is no power output at the power output terminal, please check the power cord or power socket-outlet.

2 If the power is turned on, the power indicator lights, but the machine does not work when operator presses the SWITCH button. Please check whether there is a disconnection. If there is a disconnection, please connect it in time. If there is no disconnection of the relay, indicating that the counter is damaged, the counter should be replaced in time.

3 When the number of times set on the counter is finished, but the motor does not stop working, indicating that the counter is damaged.

4 If the power indicator light is on but the counter has no display, it means that the counter is damaged and the counter needs to be replaced.

Test purpose: Used to detect the friction resistance of the markings of household and similar electrical appliances, household plugs and sockets, and couplings. It can also be used for friction resistance tests of other products such as digital markings on cables.

Test principle: The fixture for mounting the sample is driven by a motor to move back and forth, and a cloth soaked in water is placed under the friction head. The sample is rubbed with different media. The friction head can be loaded according to the test requirements.

Equipment structure: According to the standard requirements, different types of samples are installed on the equipment. The label is aligned with the test pressure head, and a cloth soaked in water is placed under the pressure head. Repeat 10 times at a speed of 1 time/s. It stops automatically when the number is reached (other test requirements: replace the cloth soaked in gasoline, repeat the test 15 times, and verify the wear resistance of the label).

Equipment dimensions: Approximately: 500×500×600 (mm) W×H×D, equipment weight: 60kg

Use environment: Power supply: AC220V±10%/50-60Hz

Test stations

Two stations

Electrical control mode

Button control

Drive mode

Electric

Sample clamping mode

Mechanical clamping, clamping point position adjustable

Test stroke

10-60mm, adjustable(Manually adjustable)

Speed

5-60 times /min, adjustable

Counter

0-9999 adjustable

Weight

50~1000g, superimposed (two each of 10g, 20g, 50g, 100g, 200g, 500g)

Voltage

AC 220V, 50Hz

Accessories

2. Alcohol or other liquid friction fixtures: two

3. Rubber sassafras friction fixture: two

4. Pencil friction fixture: two

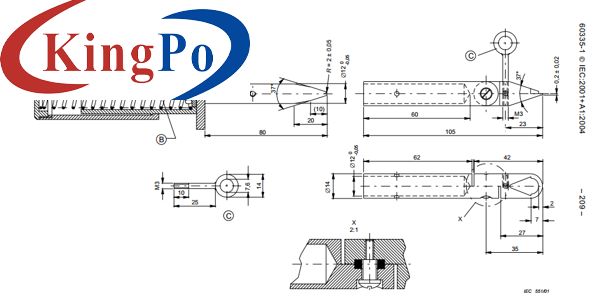

5. Add 2 friction heads as shown below