Events

Mastering Button Snap Pull Tester Techniques

News 2025-04-05 32

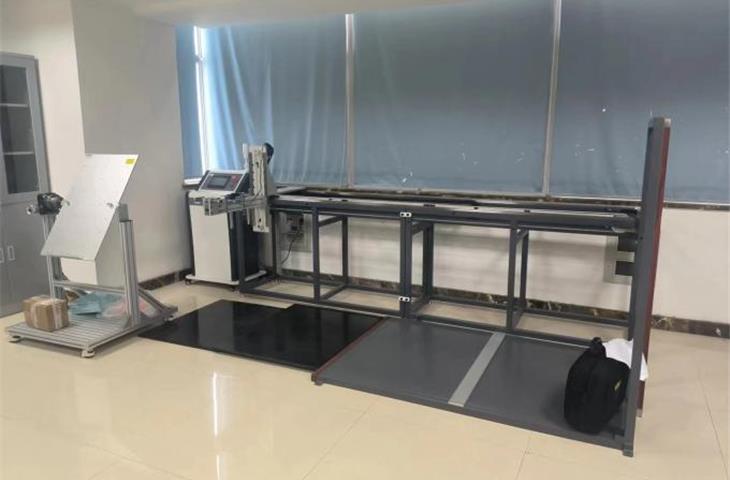

I'm a quality assurance inspector, and I've utilized numerous testing equipment, like the button snap pull tester. It's a significant aspect in producing goods to make sure buttons last and function properly. Today, I'm going to chat about five big terms related to it and how they make testing smoother.

Button Durability Tester

The button snap pull tester's real trick is measuring how tough buttons are. It's key for making sure they can handle daily wear.

I've tested buttons from all sorts of brands, and it's been pretty surprising. I once tested some buttons for a high-end fashion brand. Turns out, they weren't as strong as they should be, so they had to recall them and make modifications.

Button Pull Strength Tester

The Button Strength Testing Device is another must-have instrument. It assesses how much power it takes to pull a button from a garment, giving us information on how strong the button is.

I remember conducting tests buttons for a athletic equipment manufacturer. The tester indicated their buttons were weaker than they should be, which could suggest buttons falling off during play. They reacted with urgency and implemented enhancements.

Button Quality Assurance

Button Quality Control is a big deal in producing goods. The button snap pull tester helps ensure buttons meet the required specifications.

I've collaborated with customers who've used this instrument to detect and resolve defects in the early stages. It conserves resources and improves customer satisfaction.

Button Testing Equipment

The button snap pull tester and other testing equipment are super important for any quality assurance team. They help ensure products are excellent.

I've trained new quality assurance staff on how to use this gear, and they've enjoyed it. One trainee even said the button snap pull tester was a game altering, helping them resolve issues more quickly.

Button Strength Tester

The Button Tensile Strength Tester is a major significance for seeing how durable the buttons really are. It measures the force required to break it, giving us a insight into their sturdiness.

I've conducted button tests for a variety of industries, from apparel to automotive. I recall once button testing for a automotive seat manufacturer. The the tester indicated their buttons were insufficiently strong, which could be hazardous. They promptly implemented changes to address that.

Related articles

- How a Caliper with Dial Enhances Precision and Efficiency

- Chroma8910 in Automated Electrical Safety Testing for Medical Devices

- Essential Aspects of Climate Testing Equipment

- The Comprehensive Guide to Wedge Test Finger Wedge Test Finger

- Medical Electrical Safety Inspection Equipment: Ensuring Safe Healthcare

- The Necessities of Built-In Test Equipment in Modern Manufacturing

- Who Buys Used RF Test Equipment? A Comprehensive Guide

- The Significance of SN4410: A Comprehensive Insight