Events

Why Plastic Testing Machines Are Essential

News 2025-04-11 23

As the world becomes increasingly aware of the ecological effect of polymer debris, the role of plastic testing machines has never been more crucial. These advanced equipment are vital for ensuring the efficiency and reliability of plastic products, from consumer products to manufacturing uses. In this article, we will delve into five key topics related to plastic testing machines, exploring their importance, operational features, and the problems they encounter in the contemporary industrial scene.

1. Importance of Plastic Testing Machines

2. Types of Plastic Testing Machines

3. Advancements in Plastic Testing Technology

4. Challenges in Plastic Testing

5. Environmental Impact of Plastic Testing

1. Importance of Plastic Testing Machines

These plastic testing machines are extremely important for ensuring plastic goods are sufficiently good. They ensure the stuff manufacturers produce is durable, lasts a extended period, and is secure.

They examine all from raw materials to the end product and recycling process process process process process process. This gives us knowledge about how the plastic withstands and what might be vulnerabilities. This not only produce improved products, but it also assists reduce waste and the environmental damage.

2. Types of Plastic Testing Machines

There are a variety of different plastic testing machines out there, each designed for examining a specific aspect of the plastic. Stuff like tensile resistance testers, resistance to impact resistance testers, flow index testers, and thermal characterization instruments are pretty frequent.

Every machine has its own role, and that assists businesses in obtaining a clear view at how their stuff is doing. Knowing what each machine does and how it can help you choose the appropriate one according to your requirements is key.

3. Advancements in Plastic Testing Technology

Technology's been making plastic testing machines better and faster. Latest models often come equipped with advanced sensors, perform tasks automatically, and can analyze the data on your behalf.

This implies that the testing process is both quicker and more precise, and businesses can make more informed decisions regarding their products. Maintaining pace with such technological progress is necessary to remain competitive in the plastic sector.

4. Challenges in Plastic Testing

Despite all the technological enhancements, some issues still need resolving. The primary challenge is that that plastics can be extremely complex and exhibit significant variation.

And also, some equipment is expensive and you need experts to run it, so not everyone can get a complete test. We need to continue enhancing and collaborate with everyone, from manufacturers to scientists to the people who make the gear.

5. Environmental Impact of Plastic Testing

Even though these devices are super important for making good and safe plastic products, we can't ignore how they might affect the environment. Making and throwing these devices away can damage the environment. So, businesses and suppliers need to concentrate on being sustainable, like using environmentally friendly materials and making durable goods, to keep the damage to our earth down.

Related articles

- X-Ray Test Phantoms: A Comprehensive Overview

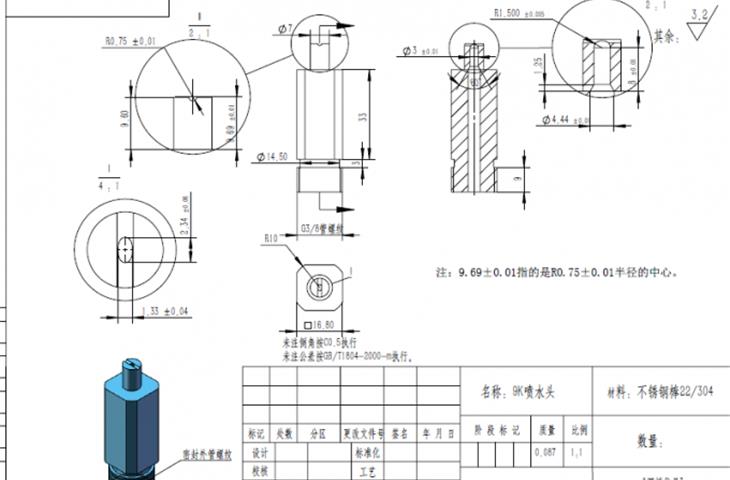

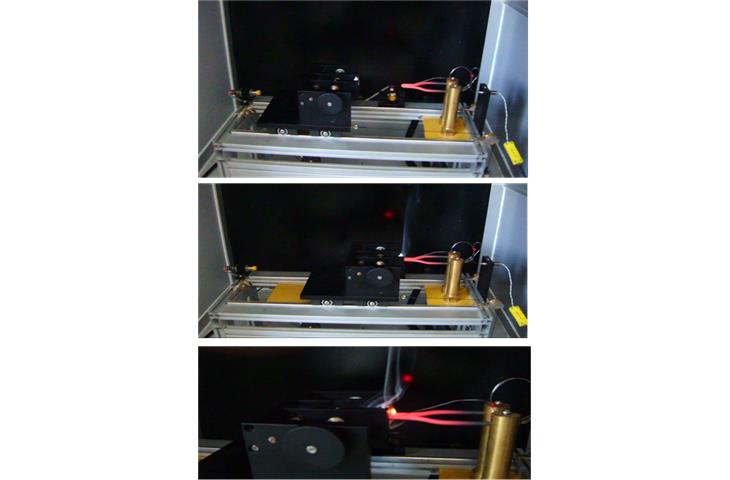

- Jet Nozzle Experiences: Insights and Needs

- When BRTirus1510a: Unveiling the Essentials

- The Essential Aspects of Medical Electrical Equipment Safety Performance Test Series

- Why UV Resistant Climate Chambers are Essential

- Decoding the Mystery of IK 62262

- CRT Explosion: Unveiling the Risks and Solutions

- Where to Find the Perfect Bursting Strength Tester for Paper Board