Events

When Tensile Strength Meets Innovation

News 2025-04-16 24

If you're in leather industry, whether you're creating items, understanding strength your hide is is key. It's all about how much stress your hide can take before it snaps—it really impacts how durable and superior your final product is.

Impact of Tanning on Tensile Strength

Finishing Techniques and Tensile Strength

Leather Production Techniques

Leather production involves several steps, each affecting the tensile strength of the end result. The choice of hides, treatment, and the surface treatment all play a significant role.

Take top grain leather, it maintains its grainy appearance and usually feels more robust than split leather, which is the one that's all smooth because they sanded it. You gotta get down with these processes—including selecting the appropriate hides and processing them to get the most durable leather for what you're making.

Impact of Tanning on Tensile Strength

Now, the way they treat those hides, or 'tan' them, is what really makes the leather pop. They could use plant stuff, or chrome, even chemicals like aldehyde.

Each type gives you different strengths—it's like a personal choice path. Vegetable tan is solid, gets you strong leather that lasts, and you'll find it in the quality leather goods. Chrome does give you a supple leather, but if you're after sturdiness, maybe not the best preferred method. What you want is up to what you're trying to make.

Finishing Techniques and Tensile Strength

After they finish it, they might perform color work, surface texture, or even wax finish. This can affect the strength of the leather, as well, while ensuring it looks good.

Engraving to give it a patinated look, but there's a trade-off—ensures a luxurious appearance but could potentially weaken it. You one must strike a balance.

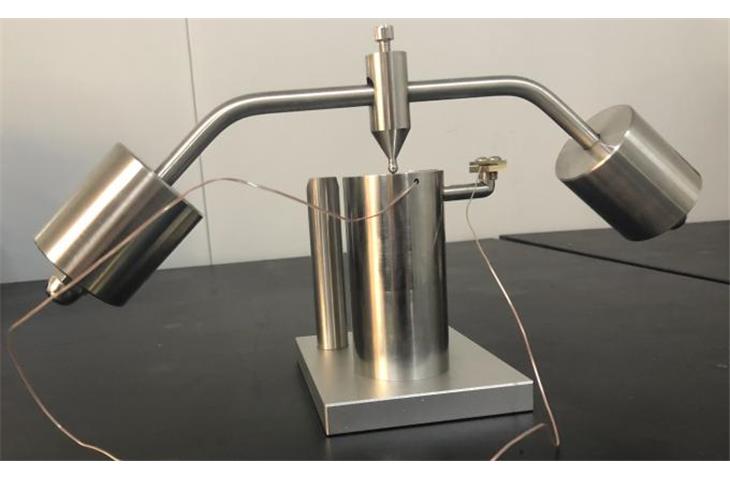

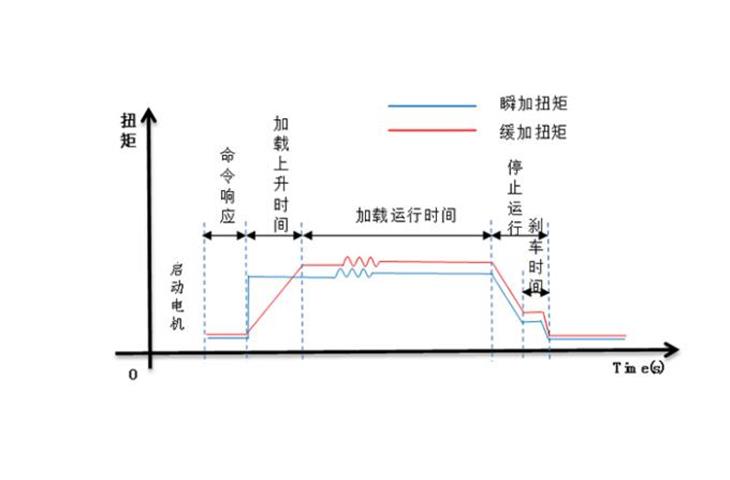

Testing Tensile Strength

They ensure the material can withstand using a sophisticated testing machine that subject it to repetitive force until failure. This test is necessary to determine if it is strong enough to do the job. So, with this info, manufacturers and designers can assess the quality of the leather to utilize it appropriately.

Conclusion

This is significant for the industry, knowing what makes leather strong. By examining the processes used in producing, prep, and finish it, we can expect the leather to maintain strength, retaining an attractive appearance, and fulfilling its intended purpose for users.

Related articles

- Unveiling the Power of Tensile Strength: Who's on Top?

- The China Abrasion Resistant Steel Company: A Comprehensive Insight

- Testing Equipment 101: A Beginner's Guide

- Decoding UL498 Figures: Essential Requirements and Applications

- What is a Cables Heat Aging Test Chamber?

- Used Test Equipment Buyers: A Comprehensive Guide

- What is GB2626-2006 Mask Performance Test?

- Essential Electronic Testing Equipment List and Its Demands