Events

Unveiling the Essence of Wear Resistance Testing

News 2025-04-19 14

You know, assessing material resistance to wear and tear is super important, especially in factories and stuff. So, they subject materials to a specific test that's like real life, to observe their response to wear and tear. Determining the behavior of materials when they're stressed helps engineers select appropriate materials and create improved designs.

Material Testing Methods

Methods of Material Testing are essential tools in wear resistance testing. They often use an examination involving a rotating disc with the material applied to it and a pin is pressed against it to mimic wearing down.

This evaluation is great for figuring out how rapidly the material deteriorates and for analyzing diverse materials. There's also the ball-and-disc assessment, where they put a sphere on a revolving plate and apply a certain load to it to create a wear groove. These tests not just provide information about the extent to which a material withstands deterioration but also give you info on the degree of its strength.

Wear Mechanisms

Understanding the reasons behind material wear is fundamental to understanding the experimental outcomes. The primary methods material wear occurs are adhering to each other, , wearing down from stress, and getting eroded by stuff like fluids or particles.

Adhesion is when materials stick to each other due to the interaction of their surfaces, which results in wear. Abrasive Friction Force is when stuff gets rubbed off because of Friction Force, like when items slide over each other. Fatigue Deterioration happens when material wear occurs from being loaded and unloaded over and over, which may eventually cause them to fail. Erosive Process is when a forceful impact by fluids or particles onto a material, like a river or sand, and wear it down. Identifying the predominant wear mechanism assists you in selecting appropriate assessments and planning remedies.

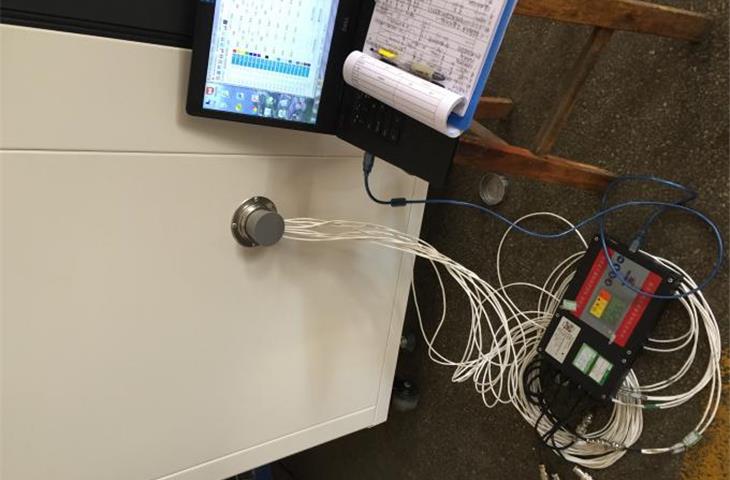

Wear Test Equipment

The kind of machinery they use for testing how substances abrasion depends on what substance it is and what kind of abrasion it's supposed to handle. They usually have machines that can do different tests, like the pin-on-disc test and ball-on-disk test ones.

They also use something called contact resistance and abrasion measurement devices to measure contact resistance and abrasion when everything's nice and controlled. These gadgets have sensors that can catch data on how much a substance abrasions down, how much contact resistance there is, and other stuff. It's super important that the machinery is good and gives you dependable results you can count on.

Application in Industry

Testing how substances abrasion is super important in lots of industries, like cars, aeroplanes, and manufacturing plants. In the automotive industry, knowing how substances in powerplants, transmissions, and stopping systems abrasion out is key to making durable vehicles and perform efficiently.

It's identical in the aviation industry. Aircraft components' materials must endure extremely harsh conditions and deteriorate over time. Employing wear resistance testing assists engineers select superior materials and develop improved designs, thereby enhancing the functionality and have longer lifespans.

Related articles

- Unlocking Precision: Free Calibration Services Close to You

- Torque Tester 0: The Ultimate Guide

- ISO 80369-7: Navigating the Standard for Orthopedic Implants

- Visit the World of Luer Lock Connector Syringes

- Copper Brazing Machine: A Comprehensive Guide

- Maximizing Twitter Engagement: Site Listeners

- Strategies for Navigating the USA Surgical Instruments Market

- Tvs8: The Ultimate Guide