Events

Foam Tester Mastery: Understanding Strength

News 2025-04-20 9

So, when we're discussing assessing foam quality, the tensile property tester manufacturer is super important. This gear makes sure the foam material holds up and works as it should. We're going to explore five key questions about foam strength testing. We'll give you some insights and real-life examples in order to assist you gain a deeper understanding of it.

Alright, so what's tensile strength, and why does it matter for foam?

How does a tensile strength tester work?

What factors can affect the tensile strength of foam?

What are the benefits of using a professional foam tester manufacturer?

How can foam tensile strength testing improve product quality and safety?

Alright, so what's tensile strength, and why does it matter for foam?

Tensile resistance is the most stress a substance can endure before it fractures. And for cellular substance, this is significant because it tells us magnitude of force it can handle before it begins to flex or deflating. If a cellular substance has high tensile resistance, it will maintain its form even when it's carrying a lot of load.

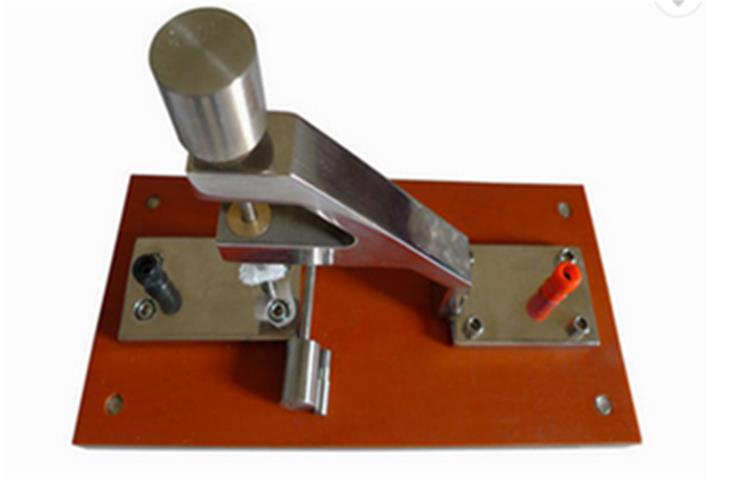

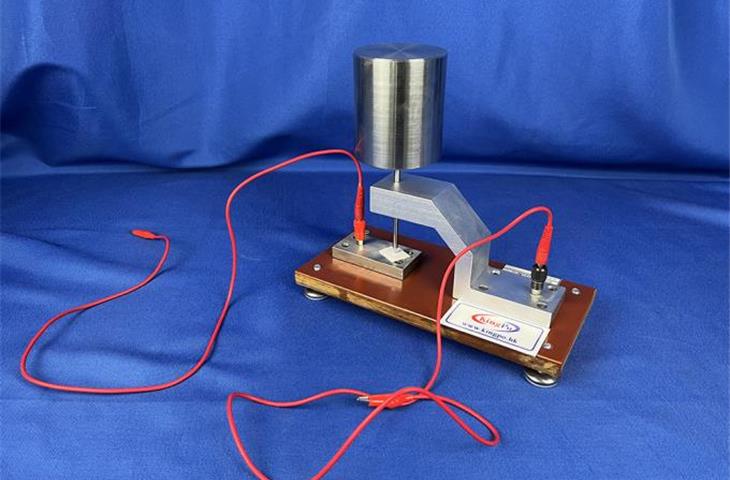

How does a tensile strength tester work?

A tensile resistance tester is similar to a device that exerts force on a cellular substance sample up to the point of failure. The device calculates magnitude of the required force to rupture the test piece, and that allows us determine the cellular substance's strength. This procedure delivers an precise evaluation of the cellular substance substance's physical structure soundness and behaviour.

What factors can affect the tensile strength of foam?

Foam's strength can be affected by factors including its material, how closely packed it is, the temperature, and how it's made. For instance, a more dense foam can become stronger since its cells are all well compacted together. The process of its production can further enhance its strength by altering the arrangement of the cells and the material's molecular structure.

What are the benefits of using a professional foam tester manufacturer?

Choosing a reputable foam tester manufacturer is a wise decision. It offers many benefits. These professionals are skilled, possess extensive experience, and utilize various advanced technology to ensure accuracy in the testing process.

Not only are they about the machines—they will train you, maintain them running, and assist you when you require it. While using their equipment, you can be confident in your foam meets standards.

How can foam tensile strength testing improve product quality and safety?

Assessing the foam's strength is essential to ensure the product is of high quality and safe. Identifying and correcting weaknesses in the foam improves the quality and durability of your product. This satisfies your customers and greatly reduces safety risks.

Related articles

- Where Textile Garment Testing Meets Quality Assurance

- China's Lighting Production Inspection: A Comprehensive Overview

- Used Testing Equipment Electrical: A Comprehensive Guide

- Choosing the Right High and Low Temperature Heat Chamber Supplier

- Why the Leather Water Test Matters in Quality Assurance

- Top 5 Paint Rub Tester Supplier Needs

- Decoding the Code: Unveiling 80601-2-69

- The Essential Aspects of Vehicle Rolling Test Devices