Events

Unveiling the Secrets of Thermal Shock Test Chambers

News 2025-04-24 22

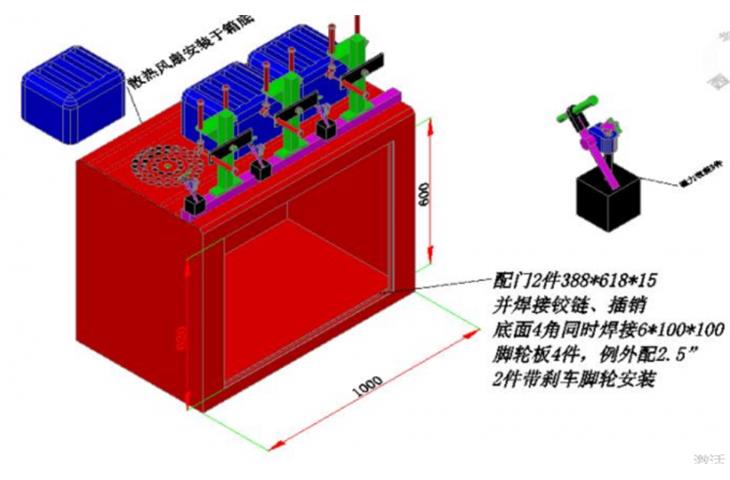

You know, these thermal shock test chambers are super important in lots of business sectors. They make sure that materials can handle big temperature fluctuations without breaking. So, these test units are like little simulators for temperature. They duplicate what materials face in the actual conditions, with temperature extremes all combined. Alright, let's explore the exciting field of thermal shock test chambers. We'll talk about why they're so important, what they're used for, and some new tech materials.

Temperature Control

Temperature Regulation is like the key element of these test test units. They've got these sophisticated mechanisms that can rapidly change the internal temperature from extremely cold to extremely hot quickly.

This is crucial because it evaluates how materials handle a abrupt change from from cold to warm, which could lead to stuff to split or break. Like, NIST conducted a research and showed that getting the correct temperature is huge ensuring the reliability of the tests.

Consider the aerospace sector, for example. They utilize these equipment to ensure components can withstand the extreme temperature variations while flying. Boeing states their chambers are extremely vital to inspect the toughness of materials such as titanium and aluminum within aircraft.

Material Testing

These testing facilities are highly beneficial to assess how materials withstand under harsh conditions. Scientists and technicians utilize them to observe how various materials perform when it becomes extremely hot or cold.

Ceramics, plastics, and metals are frequently tested to assess their response to significant temperature variations. The ASTM report indicates that material testing is crucial for developing new products that is durable and is not prone to breaking.

One notable case is the automotive industry, where thermal shock test chambers are used to test the durability of vehicle components, such as wheel hubs and motor parts. Ford's investigation shows that their chambers have helped improve, more dependable car materials.

Environmental Testing

And there's more. They're also great for testing how materials handle various atmospheres. These chambers can emulate diverse environmental states, such as moisture, force, and heat, to evaluate the functionality of composites and items under extreme conditions. This is really important in places like drugs, where they need to make sure products remain effective and enduring, even in various atmospheres.

The EU Pharmacopoeia Commission research shows that testing in various atmospheres is vital to ensure drugs stay effective and safe for the whole time they're on the shelf. For instance, they use these chambers to test insulin devices to make sure they're consistent even when it's temperate or frigid while they're transported or stored.

Advancements in Technology

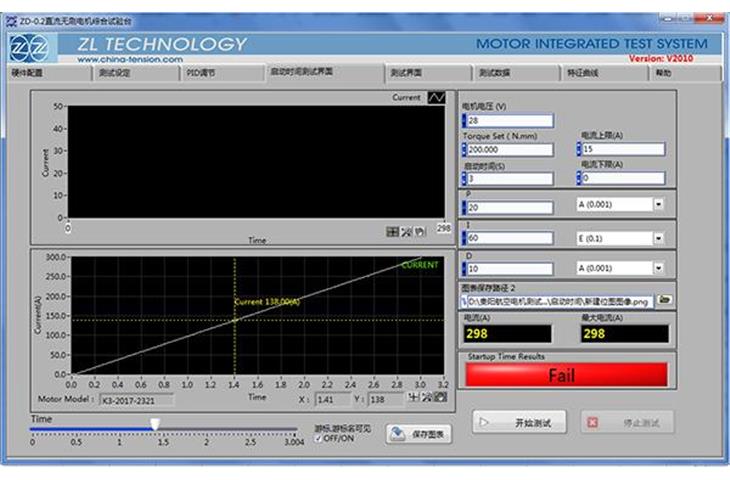

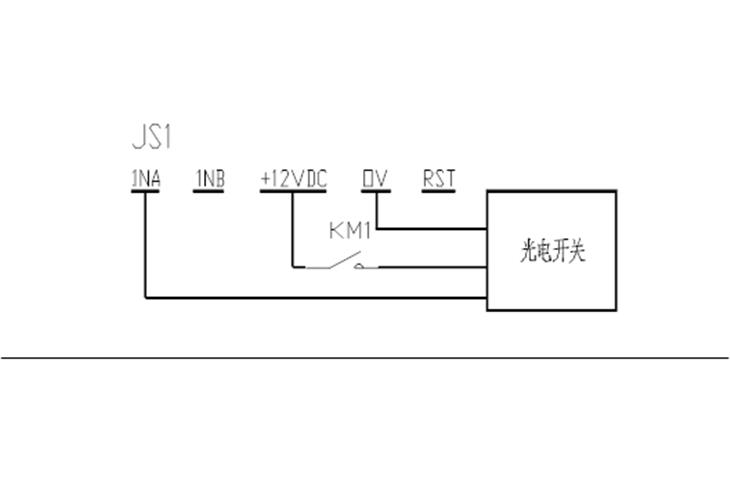

The technology in these facilities has really made significant progress over the years. Now, these contemporary facilities have really cool temperature control systems, sophisticated data features, and are extremely user-friendly. All These enhancements facilitate testing significantly more precise, faster, and easier for a bunch of various individuals to use.

The Journal on Thermal Analysis and Calorimetry talks about how these these chambers are improving further with computerized regulation and innovative data applications. These advancements not only enhance the reliability of the tests but also reduce the duration and effort required for them.

Related articles

- Essential Testing Equipment for Chorionic Villus Sampling

- What is a Pendulum Hammer Striking Tester and Its Key Demands

- Top 5 Best Sources for Aftermarket Wheels

- Optimal Calibration Frequency for Test Equipment

- What Energy Efficiency Means and Why It Matters

- Navigating Test Equipment Depot Jobs: Key Opportunities and Demands

- Unveiling the Significance of UL 1447

- Top NDT Test Equipment Distributors in USA: What You Need to Know