Events

Innovations in Textile Fabric Testing Instruments

News 2025-04-25 11

These fabric testing devices are extremely important. They make sure the fabric in a variety of sectors is excellent and performs well. So, as someone who's into textiles, I've witnessed these gadgets have changed and impacted the industry considerably. In this article, I'm gonna dive into five really engaging topics about fabric testing. I'll give you the dirt on how important these are and how they've changed the game for us.

1. The tech side of fabric testing is totally rad. Big advancements here!

5. Then there's the high-tech stuff. 'Smart' fabric testing instruments are making waves.

1. The tech side of fabric testing is totally rad. Big advancements here!

The thing about fabric examination is it's underwent massive evolution. It's mostly thanks to how tech has progressed forward. Ditching the conventional techniques for digitized approaches completely changed the fabric examination process.

For instance, electronic microscopes are awesome. They help us get highly detailed and precise data on textile fibers. Using this technology accelerates the process and gives us higher precision outcomes. By assessing the performance of fabrics tested using conventional techniques with those tested using digital technology, we can observe a considerable disparity in precision and effectiveness.

2. Then there's all this talk about eco-friendly fabric. The tools for testing how eco these materials are are getting lots of buzz.

As more and more people care about eco stuff, there's this big push to make textile products more friendly to the planet. These testing devices are super critical to determine what kind of environmental footprint these fabrics have.

They can tell us about all the substances in fabrics, even the undesirable ones like formaldehyde and heavy metals. Using these instruments helps manufacturers make sure their products is as environmentally responsible as it claims to be. I myself worked on an initiative in which we used environmental testing instruments to test the chemical makeup of the textile, resulting in the development of environmentally responsible products that were well-received by the market.

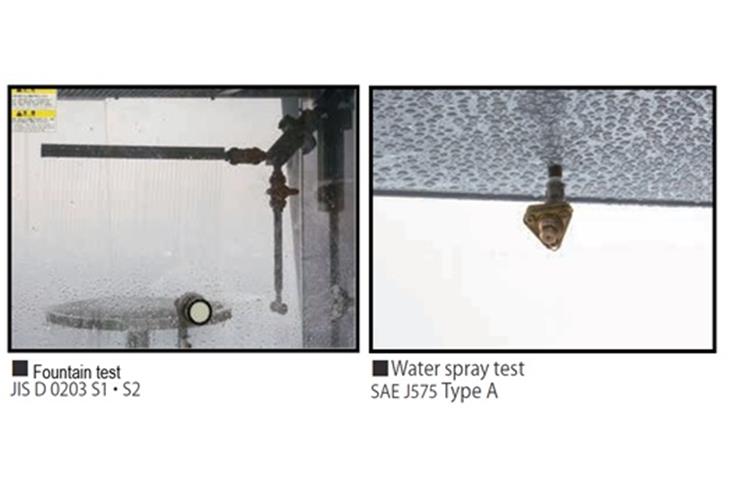

3. We've also got this super cool gear for figuring out how fabrics will hold up under harsh conditions. This wear and tear testing stuff is pretty cool.

Knowing if fabric will withstand to the tough conditions is important in our field. This decay stuff ensures fabrics won't fall apart after a few washes or uses.

These devices duplicate everyday circumstances, such as wear, rubbing, and ultraviolet radiation, to determine the fabric's withstanding damage. By using these devices, we can create fabrics that are stronger and long-term. A recent task I was taking part in demanded that we use durability testing instruments to create a material that could hold up under extensive use in athletic equipment. The results were impressive, as the fabric showed excellent withstanding damage.

4. Next up is the oldie but goodie – quality control and assurance. We need to make sure what we're putting out is the best, right?

Keeping up with quality is huge in the textile sector. Textile testing equipment is all about making sure products meet standards and hitting all required specifications.

They can check a bunch of stuff like how strong the fabric is, how it shrinks, and if the color remains consistent to the fabric. By using these instruments, manufacturers are able to determine and correct any quality problems before the products are released to the market. A example I encountered involved a manufacturer facing difficulties with color fastness problems in their fabrics. By utilizing a textile fabric testing device, they were able to identify the source of the issue and carry out a solution, leading to a substantial enhancement in product standard.

5. Then there's the high-tech stuff. 'Smart' fabric testing instruments are making waves.

Getting those Internet of Things (IoT) gizmos involved is like hitting a jackpot in the world of smart textile testing. These devices gather and transmit data related to who is scheduled to collect rent at the end of the day. It helps track fabric performance through and through.

And what's exciting about this is they can connect to the web. This lets people access and inspect data from afar. This technology has made it simpler for manufacturers to optimize their manufacturing processes and curtail expenses. I have experienced the advantages of using smart textile testing instruments in a initiative in which we managed to monitor the functionality of textiles in live, which resulted in prompt intercessions and improved end product quality.

Related articles

- China's Leading Factory Inspection Equipment Manufacturers: A Comprehensive Overview

- The Essential Role of the Pendulum Conductor

- What is the Compressive Strength Check of Concrete by UTM?

- Where China's Drawer Automated Storage Shines

- Why Falling Weight/Drop Impact Tester Quotes Matter

- Innovations in Battery Combustion Test Machine Technology

- The Essential Role of Testing Instruments in Modern Technology

- Jet Nozzle Coupon Mastery: Real-Life Experiences