Products

IEC 60335-2-24 Hydraulic Pressure Test Apparatus For Pressure Resistance Test

Products Description

IEC 60335-2-24 Hydraulic Pressure Test Apparatus For Pressure Resistance Test

Product Information For Hydraulic Pressure Test Apparatus:

This testing machine conforms to IEC60335-2-24:2017 clause 22.7 and clause 22.103, etc.

It is used for pressure resistance and leakage test of compression appliances using flammable refrigerants and appliances using trans critical refrigeration systems.

The main components of this machine adopt mature products independently produced by our company.

Technical Parameters For Hydraulic Pressure Test Apparatus:

Power required:220V, 60Hz

High pressure:0-48Mpa

Pressurization speed: ratio is controllable, adjustment range 0-2.5MPa/S

Measurement accuracy:±0.5%FS

Pressure holding time: arbitrarily set, with seconds as the time unit.

Data acquisition: American NI high-speed acquisition card, the acquisition rate is 100,000 times/S.

Peak Record: Recorded by Labview Software

Test station: Single

Exhaust system: Automatic

Test medium: Clean water

Volume :30L

Temperature:Room temperature

Control system: automatic controlled by Computer

Computer: DELL

Control software:Labview software

Test report: Microsoft Office

Equipment dimensions and weight: L 1800mm* W 700mm*H 1330mm, approx. 190KG

Equipment Composition And Characteristics For Hydraulic Pressure Test Apparatus:

1 The hydraulic testing machine uses an electric pressure test pump as a power source, and controls the solenoid valve through a pressure transmitter and a capture card to achieve testing.

2 The computer control and test bench adopt an integrated structure, the left side is the control part, the right side is the test bench. The structure is reasonable and the layout is beautiful.

3 Computer control and operation software

4 Computer automatically control system

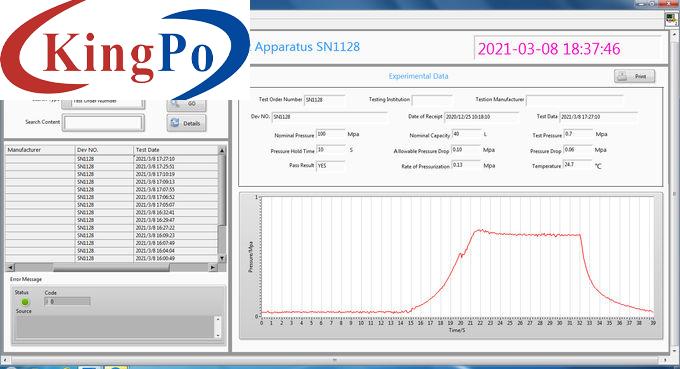

4.1 The computer displays the test process.

4.2 The pressurization speed is adjustable, pressure changes can be real-time detected, the dynamic curve can be output.

4.3 There is a special test program, operator can set test pressure and test time and other test data, the system will automatically real-time generate and print test reports, display test curves and parameters, and store test results.

4.4 English operation interface, which is concise and convenient, the update and maintenance of the control software is simple.

4.5 Recording and output function:

(1) Time-pressure curve (standard configuration)

(2) The experimental data is saved in an Excel file for easy access, storage, and modification

(3) The system can immediately generate a printable report of the time-pressure curve, the settings, interfaces and parameters can be changed according to user’s requirements.

(4) Test time unit: second

(5) Pressure unit:MPa

(6) Operator can set multi-level test pressure and pressure holding time. The computer automatically generates a standard curve. The pressure is stable at the set value during pressure holding. It has the function of comparing the actual curve with the standard curve. The two curves are displayed on the same graph at the same time.

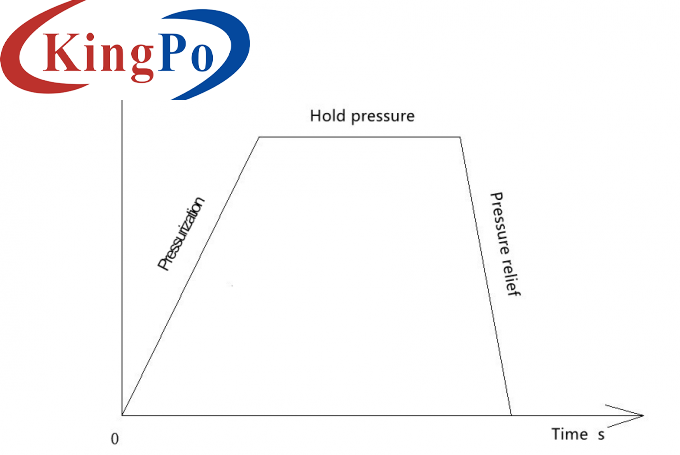

4.6 The typical test procedures that can be equipped is as follows:

Constant pressurization -pressure holding- pressure relief:

Precaution And Maintenance For Hydraulic Pressure Test Apparatus:

1 Please close the chamber door before doing test, in order to avoid personal injury due to blasting.

2 Please observe the water level during filling water into the water tank, to prevent water overflow. Please add pure water into the water tank.

3 If the pressure in the pipeline is not relieved to “0”, before unloading specimen, operator should press “Pressure Relief” button and wait until the pressure in the pipeline is relieved to “0”.

4 Please exhaust the water in the water tank if the test equipment will be in non-working status for a long time, and clean it with cloth.

5 Please clean the chamber inside after each test.

6 Please disconnect the power supply and air source when the test machine is in non-working status.