Products

Dual Stations Washing Machine IEC60335-2-7 Door Durability Testing Equipment

Products Description

IEC60335-2-7 Washing Machines Door Endurance Test System 200N 1.5m/s

System overview:

The washing machine door or lid endurance test system complies with IEC 60335-2-11:2008 clause 20.101, IEC 60335-2-7:2016 clause 18 and 22.104, IEC 60335-2-4:2006 clause 18. It is used to test the durability of the interlocking device of washing machine door or lid, and the force test when the interlock is actuated, so as to verify the reliability of the interlocking device; also used to assist other tests for repeated opening and closing operations of the washing machine door or lid.

Technical Characteristics:

Tumble washing machine door interlocking device endurance test

(IEC 60335-2-11 clause 20.101, IEC 60335-2-7 clause 18.101)

Pulsator washing machine lid interlocking device endurance test

(IEC 60335-2-11 clause 20.101,IEC 60335-2-7 clause 18.101)

Pulsator washing machine lid opening testing within the dehydration cycle (IEC 60335-2-7 clause 18.102, IEC60335-2-4 clause18)

Pull test when the interlock device is actuated to lock the door

(IEC 60335-2-7 clause 22.104)

Application:

It is used to test the durability of the interlocking device of washing machine door or lid, and the force test when the interlock is actuated, so as to verify the reliability of the interlocking device; also used to assist other tests for repeated opening and closing operations of the washing machine door or lid.

Test Principle:

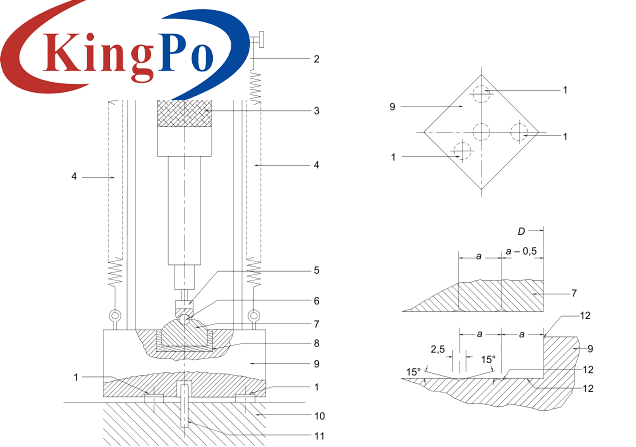

The on/off actions of the interlocking device are controlled through developed program, the manipulators are driven by servo motor to reciprocating open and close the door or lid at a certain speed with vacuum suction cup sucking on the door or fixture clamping the lid, thus, to verify the reliability of the interlocking device. A force sensor is mounted on the manipulators to form a closed loop control with the servo motors, to accurately control the door or lid opening/closing force values.

System features:

The equipment combines of electrical control cabinet (including load voltage regulating device), frame and manipulators. There are two testing station, one is for tumble washing machine with door, the other is for pulsator washing machine with lid, the two workstations can process testing independently.

Test Stations

2 independent stations, one is for tumble washing machine with door, the other is for pulsator washing machine with lid

Control Method

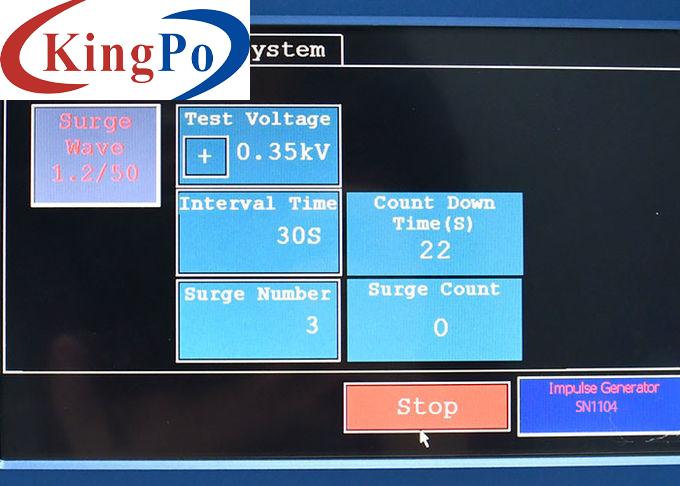

PLC intelligent integrated control, 7-inch humanized touch interface operation

Drive Mode

Servo motor drive

Clamping Method for Specimen

Vacuum suction cup, pneumatic

Door/Lid Opening or Closing Speed

0-360°/s(1.5m/s), can be preset

Door/Lid Opening or Closing Angle

0-130°, can be preset

Test Times

0-999999times, can be preset

Door/Lid Opening or Closing Force

0-200N, can be preset (the opening force value is only for the pull test when the interlock device is actuated to lock the door)

Load Voltage

0-250V, adjustable

Auxiliary Action Mechanism

Washing machine start pressing cylinder rods (can be customized)

Test Contents