Products

IEC 61591 Cooking Fume Extractor Air Volume Measurement System For Measuring Performance

Products Description

IEC 61591 Cooking Fume Extractor Air Volume Measurement System For Measuring Performance

Product information:

This test system meets the air performance test requirements of IEC 61591:2019 clause 10, AMCA 210-07, ISO5801, etc.

It is customized according to the form, material, and maximum shape of the user’s specimens, used to simulate the maximum full pressure efficiency, working air volume, maximum air volume and maximum static pressure of the specimens under specific environmental conditions, to verify whether the specimens meets the limit values required by the standard. It is suitable for air performance testing of range hoods and other cooking fume extractors with a rated voltage not exceeding 250V.

The test system adopts intelligent industrial control, large-size computer display and operation, automatic measurement. It can record and automatically print of test reports, and can analyze test results and test data.

The test system can measure and draw the corresponding curves of static pressure and air volume, air volume and speed, current, power, efficiency, etc. The specimens can also be tested in two states: inhalation and extraction, and the test performance meets the latest standards for relevant products.

Test principle and layout:

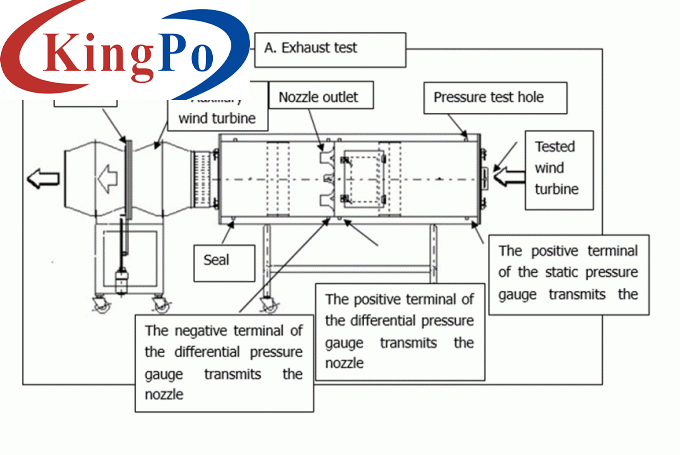

This solution adopts the blowing test mode, and controls the air volume by stepless adjusting the frequency of the auxiliary fan through the frequency converter; the middle of the air chamber is composed of a flow equalizing orifice plates, nozzles, starting actuators and nozzle plates; the chamber interface size is 600mm×600mm. This system automatically calculates the fan air volume by measuring the pressure difference before and after the nozzle. When the equipment is running, the air performance test device is run on, the air volume of the auxiliary fan is controlled by controlling the opening and closing combination of the nozzles and the current frequency of the frequency conversion device. The static pressure under the corresponding air volume is measured by a high precision micromanometer, so as to obtain the corresponding data of the air volume and air pressure of the specimen, and draw the air volume and air pressure curve. The system is compatible with the air performance test of two types of range hoods: external exhaust type A and suction type B.

Technical Parameters:

Pa

0~2000

Voltage

V

0~300V

Current

A

±(0.15% of reading + 0.50% of range)

±(0.25% of reading + 0.50% of range)

10Hz≤f<45Hz

45Hz≤f<440Hz

Temperature

°C

-20~80

±0.2°C

RPM

0-5000

±5 RPM

Table 1

Item

Unit

Scope

Accuracy

Other

Air volume (flow rate)

m³/min

0~50

±2%

Static pressure/differential pressure

Full scale ±0.055%

Response time does not exceed 90ms

±(0.15% of reading + 0.35% of range)

10Hz≤f<440Hz

0~5mA 0~20A

±(0.15% of reading + 0.35% of range)

10Hz≤f<440Hz

Power

W

0~5000W

With a temperature gauge with a display accuracy of at least 0.1°C

Humidity

%

0~100

±3%RH

Humidity meter with 0.1%RH

Atmospheric pressure

kPa

0-200

≦±200Pa

Barometric pressure sensor

Speed (standard configuration)

Measuring distance 5~100 cm