Products

Electric Rice Cookers Energy Efficiency Lab 2 Test Benches 6 Black Corners

Products Description

Energy Efficiency Testing System with 2 Test Benches 6 Black Corners for Electric Rice Cookers

Overview:

This testing laboratory provides test conditions for energy efficiency testing of rices cookers, meets following standard requirements:

GB 12021.6-2008 (2017) Minimum allowable values of energy efficiency and energy efficiency grades for electric rice cookers.

Heating efficiency calculation for electric rice cookers:

Where:

η Heating efficiency, accurate to one decimal place

1.16 Constant, dimensionless

λ Correction factor. For specimen which is heated by electromagnetic induction, λ value is 1.15, which is heated by the electric heating element, λ value is 1.0; which inner pot material is non-metal product, λ value is 1.13; which inner pot material is non-metal and is heated by electromagnetic induction, λ value of 1.15.

G The amount of water before the test, unit is KG

t2 Maximum water temperature after the test, unit is Celsius (℃), accurate to one decimal place

t1 Initial water temperature before the test, unit is Celsius (℃), accurate to one decimal place

E Power consumption, unit is watt hours (W.h), accurate to two decimal places

Standards:

Can be designed according to the following standards:

► GB 12021.6-2008 (2017)

► Other international standards

Types of UUT :

Electric Rice Cookers

Test Room Size:

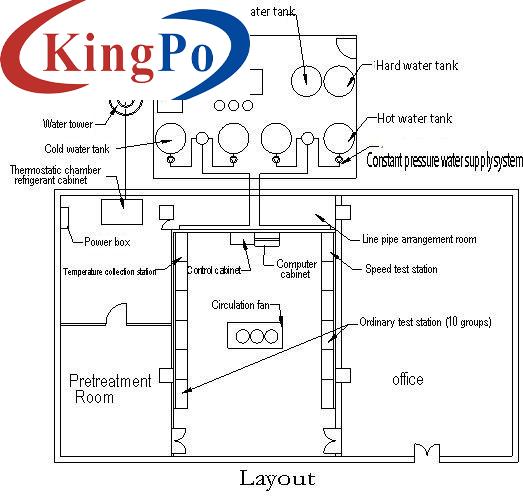

4.2M (Length) *2.75M(Width),The schematic layout is as follows:

Note: The air-conditioning environment in the room is realized by the existing air-conditioning of User, and the structure of the house is completed by User.

Configuration List:

No.:

Name

Specification

QTY

Unit

Test Stations

1

Test benches

Plates, with drawers and cabinets (a set of 3 stations)

2

SET

2

Test corners

1M* 0.8M* 0.6M (H*L*W),20mm thickness plywood, surface coated with a matt black finish

6

PC

Electrical Testing

4

Thermocouple

T type -20~150℃ Accuracy 0.1class

40

M

5

Isothermal terminal

Omega

12

GROUP

6

Electrical parameter meter (single phase)

WT310E

6

SET

7

Data collector

Yokogawa GM10 (two channels per each station)

2

SET

8

Frequency Power

15kVA

1

SET

9

Power box and terminal box

Stainless steel

6

SET

10

Electrical parts and wire conduit, etc.

Air switch, contactor, relay, power supply switch, etc.

1

SET

11

Test software

The latest version, matching hardware transformation, in line with the latest standards

1

SET

12

Computer

Lenovo business machine

1

SET

13

UPS

Santak 500VA

1

SET

14

Electronic scale

(±0.1%), 5g resolution,20kg measuring range

2

SET