Products

IEC 60879-2019 Energy Efficiency Lab Ceiling Fans Environmental Test Chamber

Products Description

IEC 60879-2019 Ceiling Fans Environmental Test Chamber Energy Efficiency Testing Lab

Overview:

This test laboratory can perform the performance test of the fans in accordance with the methods specified in IEC 60879-2019 and GB / T 13380-2007. The test system can accurately measure the performance parameters such as the wind speed, air volume, fan speed, fan power consumption, fan energy efficiency value of ceiling fans and decorative ceiling fans, and can realize the sampling and analysis of fan products, product quality inspection, and research and development requirements.

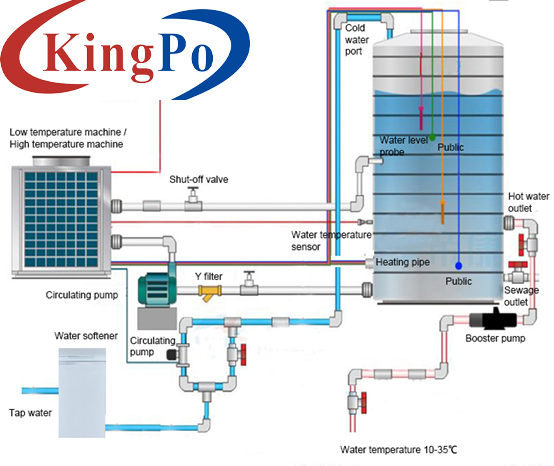

It is a comprehensive single enthalpy difference chamber. The laboratory contains a set of air volume measuring devices. The test chamber uses 100mm thick rigid polyurethane board and 0.6mm thick color steel plates on both sides for thermal insulation, which has good thermal insulation effect.

This test room contains an external air conditioning system, which is used to adjust the air environment inside the test room. The indoor air is cooled, humidified, and heated to make the temperature and humidity in the test room meet the requirements of the test conditions.

This laboratory needs to be equipped with an operating room for storing office computers, power cabinets, control cabinets, and variable frequency power supplies. This house can be constructed by boards, which is constructed by the buyer (generally next to the laboratory).

This test system is mainly controlled by computer. The operator is outside the test room, and the personnel will not affect the wind field. The test of the equipment is completed automatically, and the test data is recorded, saved, and the air flow report and energy efficiency rating are automatically generated. This system has advantages of good repeatability, high efficiency, convenient data storage and so on.

Standards:

Can be designed according to the following standards:

IEC 60879-2019 "Comfort fans and regulators for household and similar purpose- Methods for Measuring Performance "

GB/T 12021.9-2008 "Minimum allowable values of energy efficiency and energy efficiency grades for AC electric fans "

GB/T 13380-2007 “A.C. electric fans and regulators”

Types of UUT :

*Ceiling fan:900~1800mm

Test Contents:

* Wind speed

Laboratory Measurement Instrument Indicators:

Laboratory Room Structure:

Experimental Measuring Device:

Main Technical Parameters:

1. Lifting range of sample stage: 900-1800mm.

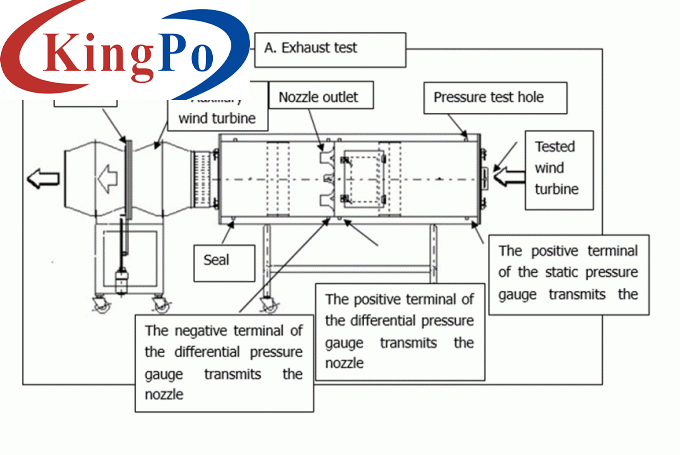

Ceiling fan test principle and method:

1. First, install the ceiling fan through the ceiling fan lifting column, and arrange the anemometer device below 1500mm from the fan blade plane.

2. Adjust the temperature in the test chamber to meet the test conditions (20 ° C), and start the test after running the fan for 1h.

3. Before testing, it is also necessary to close the air inlets and outlets, doors and windows, and relevant personnel to leave the laboratory to ensure that the laboratory is not affected by external airflow. Then operator runs the anemometer to start collecting anemometer parameters. The anemometer device is rotated by 90 ° per minute to collect and record data (wind speed, speed, etc.) under the action of the rotating drive frame. (The data of wind speed ≥9m / min tested in all anemometers is valid data).

The laboratory is equipped with a regulated power supply, which can reduce the impact of mains fluctuations on test measurements. Fan power voltage current is measured by a 0.5-level power meter.

* Wind volume

* Rotating speed

* Speed ratio

* input power

* Energy efficiency value

No.:

Name

Content

Range

Measurement uncertainty

1

Temperature and humidity sensor

Dry bulb temperature

0~50℃

±0.1℃

2

Temperature and humidity sensor

Relative humidity

30%~80%RH

±3%RH

3

Digital Power Meter

Input electrical parameters

/

±0.5%

4

Anemometer

Wind speed

0.15~5m/s

±0.2m/s

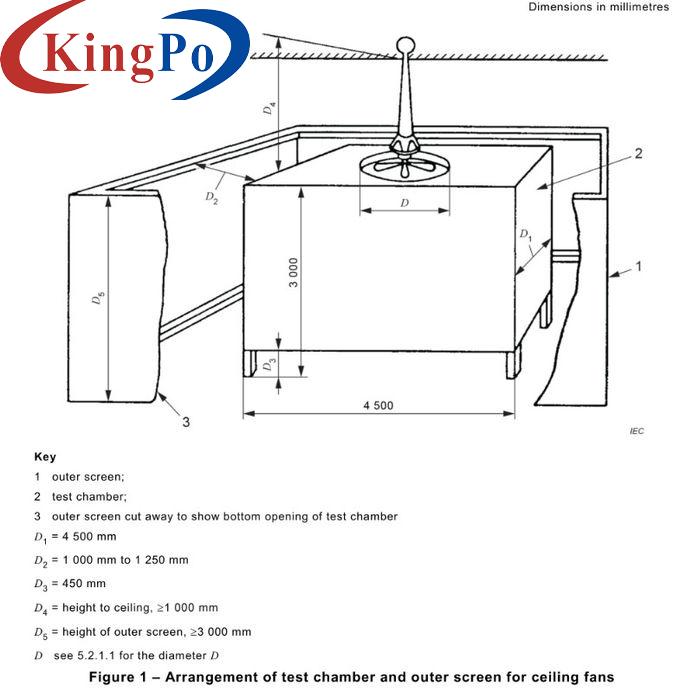

External dimensions

4700(W)×4700(D)×3100(H)

Inner dimensions

4500(W)×4500(D)×3000(H)

Laboratory maintenance structure

100mm Rigid polyurethane foam insulation

Door

Inside 1600×2200(H)×1 (Sliding doors)

Laboratory window size

1600×800mm

Device

Type

Specifications

Laboratory

Anemometer guide

Stepper motor control

Japan SanRex or equivalent, with a maximum travel distance of 2m

Ceiling fan guide

Stepper motor control

Japan Matsushita or equivalent

Sample holder

Height adjusted by screw

Customized

2. Distance between anemometer and sample:1500mm.

3. The anemometer slide moves along four diagonal lines: 40-1000mm (automatic adjustment).

4. Wind speed measuring instrument: Brand: Austria E + E, display decimal point: 0.01m / s, instrument accuracy: ± 0.2m / s

5. Impeller diameter: 100 mm

6. Measuring range: 0.40 ~ 30.00m / s

7. Measurement accuracy: ± 1% of reading + 1% of range

8. Wind speed sensitivity: better than 0.15m / s

9. Temperature probe: range 0 ~ + 50 ℃; accuracy ± 0.5 ℃

10. Driving mode: domestic servo motor + guide shaft.

11. Control method: computer control.

12. Collect data: power value and wind speed value.

13. Data processing: Automatic calculation of average wind speed, air volume, energy efficiency value, and energy efficiency rating.

14. Data storage and reference function.