Products

IEC 60335-1 House Hold Appliance Matt Black Painted Heating Test Corner

Products Description

IEC 60335-1 House Hold Appliance Matt Black Painted Heating Test Corner

WDH=600 x600x1000mm

KingPo can customize different sizes with different temperature measuring distribution according to client's specific requirements. And our test corners are well painted, the themocouples and measuring coppers are well arrayed, all the themocouples are leaded to the terminal block, which is covenient for client to connect to the temperature measuring and recording instruments.

3. Use a temperature measuring instrument with a resolution of 0.5°C and a range of 50°C to measure the indoor ambient temperature "T".

Product Overview

This test corner conforms to the standard requirement of IEC 60335-1 clause 11.2, IEC60065 clause 7, etc. It is designed and manufactured to provide the required environment for the temperature rising test of all kinds of electrical, electrical products. It can be customized according to the different testing samples.

The number on every connector socket and the test point number on the test corner are corresponding (see test point distribution).

This test corner adopts K-Thermocouple for measuring.

Specification

1. Inner size: L*W*H: 600*600*1000mm (Side plate*2, base plate*1, top plate*1)

2. Thermocouple: The diameter of the thermocouple is less than 0.3mm

3. The thermocouple arrangement: All lead on a connection line (optionally equipped with thermocouple plug and socket)

4. The sheet copper used for temperature measurement: the diameter of 15mm and the thickness of 1mm. 32 pcs of copper sheet

5.The number of temperature measuring points: 32 points

6.The arrangement of temperature measuring points: 100*100mm, square stationing.

7.Plywood: The thickness is 20mm and the front side is painted with Berlin black and the reverse side is with gray film plate.

8. The movable part: there are 4 removable wheels installed on the bottom of the device.

Technical Parameters

Equipment structure

Four-panel structure, 1 base plate, 2 side plates, 1 top plate

Dimensions

Other dimensions can be customized

Thermocouple

American original OMEGA thermocouple, diameter <0.3mm, PTFE Teflon PFA, insulation layer temperature resistance -200℃ to 260℃, core diameter: 2X0.255mm

Thermocouple Arrangement

All lead to the terminal block

Temperature Measurement Copper

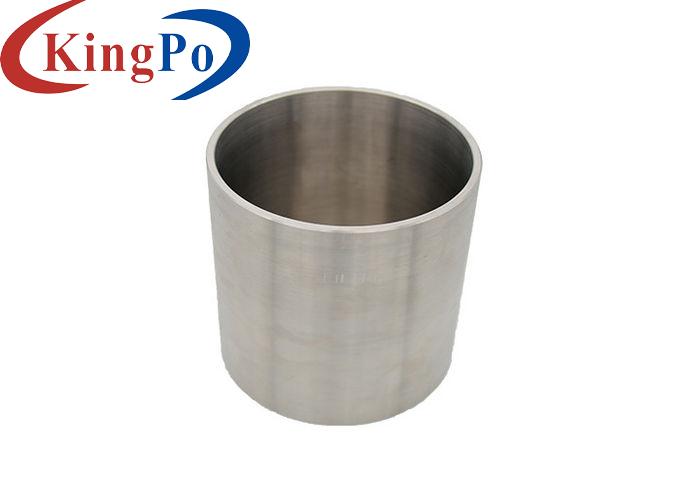

15mm diameter, 1mm thick brass sheet painted in black, the front surface of the round copper sheet is flush with the surface of the plywood

Temperature Measurement Points

32 points temperature measuring points, layout as client's requirements

Temperature Measurement Point Arrangement

100×100mm square distribution, can be customized 76×76mm or 50×50mm

Plywood

20mm thickness, matte black paint on the front and gray film on the back

Equipment features

The temperature test corner can be moved, the bottom is equipped with 2 or 3 inch flat-bottomed brake wear-resistant corner wheels, the total height is about 1000mm, and the load is ≥200kg

Optional

Temperature measuring and recording instrument

Test Method:

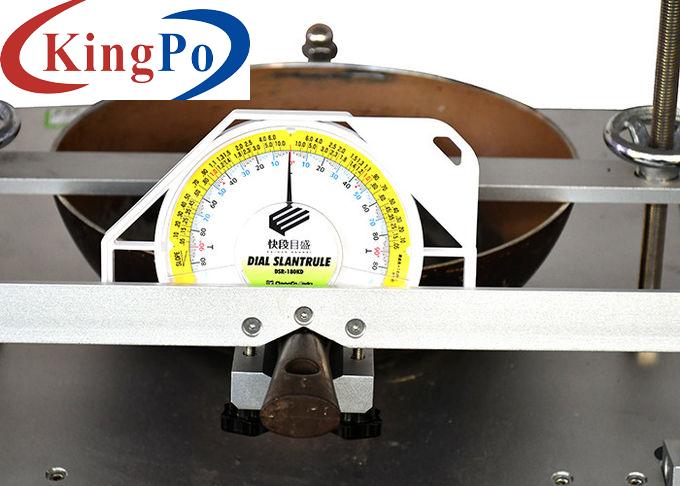

1. Prepare a thermocouple with plugs on the two ends, insert one plug into the socket of corresponding measuring point (please refer to the Attachment: Distribution map of measuring points), insert the other end into the temperature measuring instrument.

2. In order to make the temperature measuring instrument work stably, the temperature measuring instrument should be powered on before the normal test, and the measurement should be started after 30 minutes of warm-up.

4. The specimen is placed at the proper position in the test corner, and powered on.

5. After the test starts, stay for 3 to 5 minutes and then read out the indicating value "T1" shown on the temperature measuring instrument, the actual temperature value of the measuring point.

6. The temperature rise value at a certain point T=T1-T.