Products

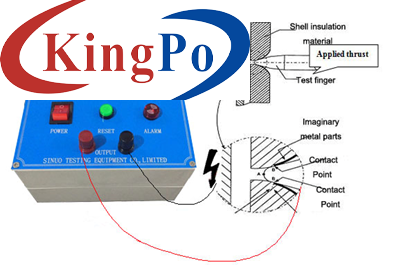

IEC 62196 Connector Temperature Rise Testing Equipment For Temperature Rise Test

Products Description

IEC 62196 Connector Temperature Rise Testing Equipment For Temperature Rise Test

Product information:

Comply with GB15287, GB15288, GB20234.1, GB2099, GB16915, GB15092, GB17465, GB11918, GB13140, GB14048, GB20234, GB7251, UL310, UL486, UL498, UL817, UL941, UL943, UL1053, UL1 059, IEC60309, IEC60998, IEC60669, IEC61058, IEC60439, IEC62196, EIA-364-70 current and temperature rise test methods for electronic connectors and other relevant standards for electrical accessories. It can be used to assess the surface heating of electrical accessories when connected to a load current and whether the electrode temperature rise meets the requirements of the standard.

It adopts independent programming software and computer-controlled operation. All standard test procedures and data judgments are controlled by the system, making it easy to operate. It is used to assess the surface heating of the charging interface and electrical accessories when the load current is connected, and whether the electrode temperature rise meets the requirements of the standard.

Technical Parameter:

1. Computer programmable current source:

Maximum output voltage: not exceeding DC5V

Output constant adjustable test current (2 sets of independent outputs, can work at the same time):

①.DC5A~100.0A digital continuously adjustable

②.DC100A~2000A digital continuously adjustable

Output voltage display accuracy: ± (0.25% reading + 0.25% range)

Current display accuracy: ± (0.25% reading + 0.25% range)

Test current stability: ± (0.25% set value + 0.25% range)

2-channel voltage drop monitoring: 1-300.00mV, display accuracy ± (0.25% reading + 0.25% range)

Impedance: calculated value of voltage drop ÷ current

2. Control mode:

Continuous mode power-on time: 1~9999.99 hours

Power-on time/power-off time: 1~9999.99 hours

Number of on-off times: 1 to 9999 times, with power-off memory function, automatic shutdown when the number reaches

3. Temperature rise test:

Temperature measurement range: 0~260℃ Accuracy ±(0.3% of reading +1℃); Resolution: 0.1℃.

Temperature measurement points: 16 channels (including 1 point for measuring ambient temperature).

Temperature measuring thermocouple: American Ω Company T-type 30AWG filament thermocouple, 2 meters long, 16 in total.

The temperature probe can be tested with electricity without damaging the instrument.

Temperature data collection: It is completed by the TWC-2A multi-channel temperature tester designed and produced by our company, equipped with RS232 communication interface and data recording interface.

Temperature scanning speed: 1~255 seconds for all channels.

Temperature data recording: automatically completed by computer, configured with computer testing software.

The software can set the ambient temperature channel, and the ambient temperature can be automatically subtracted when collecting data.

4. Equipped with special testing software:

Software functions: A. Different working modes can be set: continuous mode/on-off mode/automatic temperature control mode

B. Current flow control setting, the ambient temperature channel can be set, and the temperature rise can automatically subtract the ambient temperature

C. Automatically record data and draw curves: temperature rise/voltage/current/voltage drop (impedance)-time curve

5. Power supply: AC220V, 60Hz, 15KVA

6. Equipped with a touch screen integrated industrial control computer (Pennium 4/1.8G or above CPU, 4G memory, 64G solid state drive, 15-inch LCD monitor), installed with XP Chinese (or English) operating system and OFFICE processing software.

7. Test box: Equipped with an acrylic windproof test box about 800 wide * 400 high * 400mm deep, which is convenient for users to test.

Test fixture: user-made

Test station: The product under test can be connected in series at multiple stations, as long as the maximum output capacity is not exceeded.

8. Dimensions: Approximately 800mm wide × 800mm deep × 1800mm high, weighing approximately 450kg. The cabinet is equipped with heavy-duty brakeable movable casters for easy fixing and movement.

9. Equipped with overload protection and overcurrent protection functions

When the equipment stops, the current output is automatically cut off.

The equipment can work continuously for a long time and is stable and reliable

10. Install an electronic control output with relay (NC NO COM). Install a 220Vac outlet for fan control.

11. Add humidity sensor and computer collection data display.

12. Wi-Fi network equipment: Data can be connected to a Wi-Fi network to follow up the processes outside of the laboratory.

7. Test box: Equipped with an acrylic windproof test box about 800 wide * 350 high * 400mm deep, which is convenient for users to test.

Test fixture: user-made

Test station: The product under test can be connected in series at multiple stations, as long as the maximum output capacity is not exceeded.

8. Dimensions: Approximately 800mm wide × 800mm deep × 1800mm high, weighing approximately 450kg. The cabinet is equipped with heavy-duty brakeable movable casters for easy fixing and movement.

9. Equipped with overload protection and overcurrent protection functions

When the equipment stops, the current output is automatically cut off.

The equipment can work continuously for a long time and is stable and reliable