Products

IEC 61851-1 PLC Control System Leakage Tracking Test Equipment

Products Description

IEC 61851-1 PLC Control System Leakage Tracking Test Equipment

Product information:

The tester is designed and manufactured according to the standard requirements of IEC60112, and required by IEC 61851-1 clause 12.3, IEC 61851-23 clause 11.6, IEC 62196-1Ed.4CDV 2020 clause 28.4, 29.6, IEC60335-1 clause 29.2 and Annex N, IEC 60065:2014 clause 13.4, IEC60598-1, IEC 60884-1:2013 clause 28.2, UL746A and ASTM D3638-92 and etc.

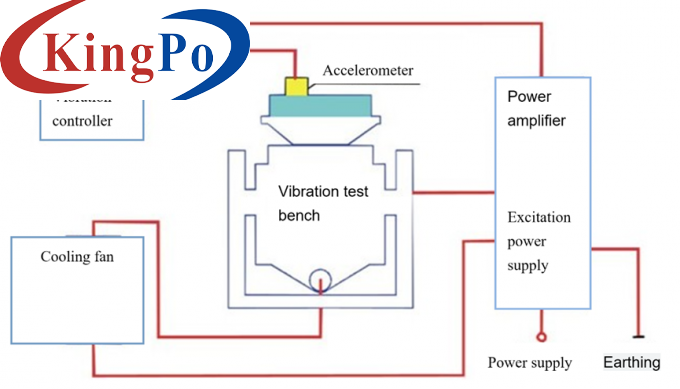

The working principle of the leakage tracking test (tracking index testing) is that the conducting liquid (0.1%NH 4 CL) of required volume in the required height (35mm) and required time (30s) drops with the voltage between the platinum electrodes (2mm × 5mm) on the surface of solid insulating material. Thus, the users evaluate the tracking resistance performance of solid insulating material surface under the combined influence of electric field and humid or contaminate medium. In a word, this device is used to measure the compare tracking index (CT1) and electrical resistance index (PT1).

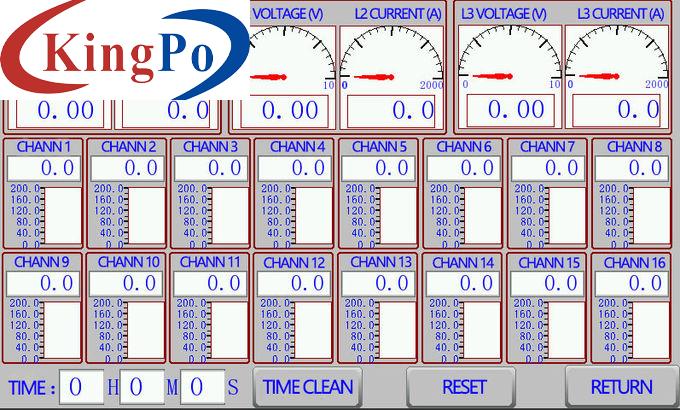

A gauge block is supplied with the instrument to ensure the electrodes have the proper distance between them. The table height is easily adjustable to ensure the proper angle of the electrodes and height of drops. The rest of the test is controlled from outside the test chamber with the door closed. The voltage, limiting current, drip rate and number of drips are all set on the control panel. An operator should observe the test to see if a flame ignites. The instrument sounds an alarm if there is a tracking failure of at least two seconds.

The leakage tracking tester adopts to advanced PLC control system and 7” color touch screen, it is suitable for the research, production and quality department of lighting equipment, low-voltage apparatus, household appliance, machine tool electric appliance, electrical machine, electric tool, electronic instrument, electrotechnical instrument, information technology equipment. It is also suitable for the industry of insulating material, engineering plastics, electrical connector and accessories.

Technical parameters:

Parameter model

SN774 (0.5m³)

Working voltage

220V/50Hz,1KVA

Control

Advanced PLC

Display

7-inch color touch screen

Testing voltage

0~600V adjustable, precision 1.5%

Timing device

9999X0.1S

Electrode

Platinum electrode and brass electrode each for a pair

Electrode dimension

(5±0.1)×(2±0.1)×(≥12),

30°slant

Electrode included angle and distance

60°±5°, distance is (4±0.1㎜)

Electrode pressure

1.00N±0.05N(digital display is optional)

The interval of dropping liquid

30±5S, adjustable

Dropping liquid height

35±5mm

Dropping liquid delay

0.2S(solenoid valve opening time)

Dropping liquid size

45~50 drip/cm3

Time-delay circuit

2±0.1S(in 0.5A or larger current)

Short-circuit pressure drop

8% MAX

Short-circuit current

1±0.1A 1%

Wind speed

0.2m/s

Environmental requirement

0~40℃, relative humidity≤80%, in the place of no obvious vibration and corrosive gas

Equipment size & weight

1100mm* 550mm* 1100mm, 180KGS

Conforms to standard

IEC60112, IEC 60598-1, IEC60695, IEC 60884-1, UL746A, ASTMD3638, etc.