Products

IEC 62196-1 2022 Drop Testing Rewireable Plugs And Vehicle Connectors Test Device

Products Description

IEC 62196-1: 2022 Drop Testing Rewireable Plugs And Vehicle Connectors Test Device

Product information:

Standard: according to GB/T20234.1-2023 "Connection devices for conductive charging of electric vehicles - Part 1: General requirements" Section 7.11.3

GB/T11918.1-2014 Chapter 24.3.

Samples and restrictions: Charging gun cable assembly.

Application: Check the mechanical strength of the charging gun cable assembly.

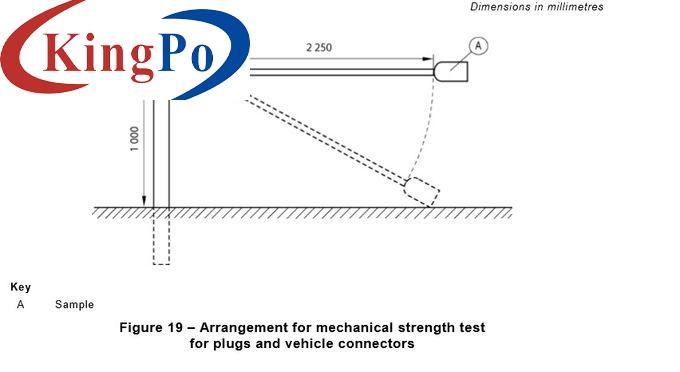

Test principle: Use a clamp to fix the sample at a height of 1000mm from the ground and drop it to verify its mechanical strength.

Usage environment: Working temperature 0-40℃, humidity 30%-90%.

Features:

The testing equipment used for drop testing rewireable plugs and vehicle connectors is designed to evaluate the durability and mechanical strength of these components when subjected to impact or dropping forces. This type of testing ensures that the plugs and connectors can withstand the rigors of everyday use and maintain their electrical integrity.

The specific equipment used for drop testing rewireable plugs and vehicle connectors may vary depending on the testing requirements and standards. However, here are some common components and features that you may find in such equipment:

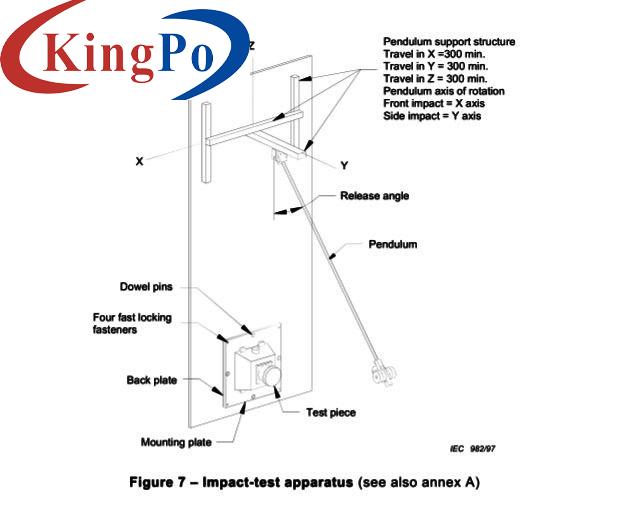

Drop Tower: The drop tower is the main component of the testing equipment. It consists of a vertical structure with a platform or fixture where the plugs or connectors are secured. The tower enables controlled and repeatable dropping of the test specimens from specified heights.

When conducting drop tests on rewireable plugs and vehicle connectors, it is important to follow relevant standards and specifications, such as those provided by organizations like IEC or UL. These standards outline specific test methods, drop heights, and acceptance criteria to ensure consistent and reliable testing results.

Technical parameters:

Test procedures (Excerpt from IEC 62196-1Ed.4CDV 2022 clause 26.3):

Non-replaceable plugs and vehicle connectors are used with short lengths (approx. 200mm) Flexible Cable Shipped.

Drop Height Adjustment: The equipment allows for adjustable drop heights to simulate different impact scenarios. This feature enables testing at specific heights or compliance with industry standards.

Specimen Fixation: The equipment includes fixtures or clamps to secure the rewireable plugs or vehicle connectors in place before the drop test. These fixtures ensure that the specimens are properly positioned and immobilized during the impact.

Release Mechanism: A release mechanism is incorporated to initiate the drop of the test specimens. This mechanism ensures consistent and controlled dropping of the plugs or connectors, minimizing any potential operator-induced variations.

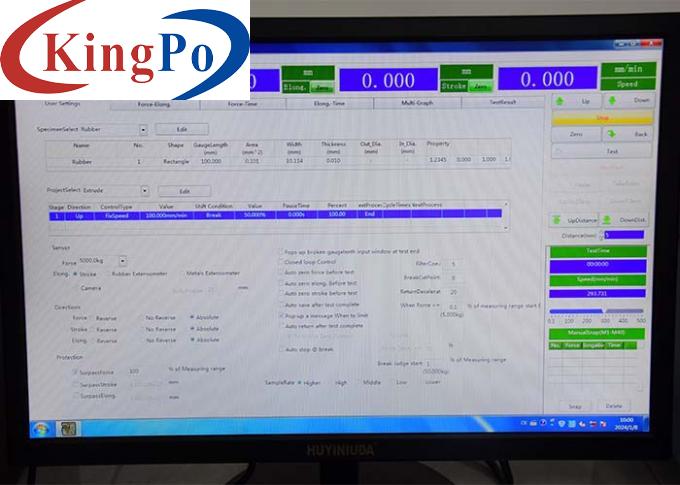

Impact Force Measurement: The equipment may incorporate force sensors or load cells to measure the impact forces experienced by the test specimens during the drop. This measurement provides quantitative data on the mechanical stress the plugs or connectors undergo.

Equipment dimensions

Approx.: 2400×850×400 (mm) W×D×H

Equipment weight

50kg

Drop height

1000mm

Distance from fixed end

2250mm

Number of drops

8 times

Rotating device

45° indexing, 8 directions rotatable

Drop method

Manual release

The free end of the cable is connected with the flexible cable by additional ropes or other flexible devices, the total length is 2.25m, and is fixed on the wall 1m from the ground, as shown in Figure 19.

Hold the sample so that the cable is level, then let it fall on the concrete floor. This was done eight times; The cable is rotated 45 ° each time it is fixed.