Products

IEC 62196-3 Electric Vehicle Pressure Leak Test Overpressure Test System

Products Description

IEC 62196-3 Electric Vehicle Pressure Leak Test Overpressure Test System

Product Information For Overpressure Test System:

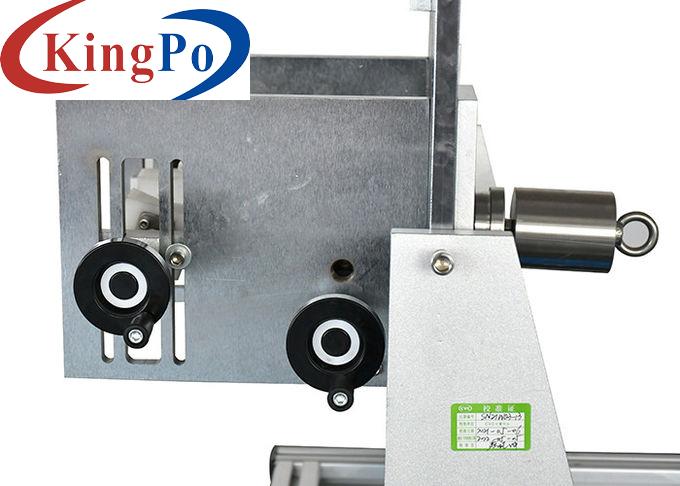

This overpressure test system meets the test requirements of IEC 62196-3-1 Cl 101.6. It is used to carry out pressure leakage test on the sealing requirements of the liquid coolants under 10L volume.

The system's booster pump outputs high pressure to verify the pressure resistance of the samples according to the different pressures of the samples. The system is composed of electrical control system, pressure control system and water tank, the workpiece is manually installed and connected.

Technical Parameters For Overpressure Test System:

WDH=500×500×1000mm

With transparent viewing window for observe bubbles

ZG1/4 internal thread

User should consider the connection between our ZG1/4 internal thread to tests samples

Power supply

AC 220V, 60Hz, 0.3KW

Test station

Single station

Electrical control method

Computer intelligent control and operation

Test pressure

1.0-10.0Bar, booster pump drive

Pressure control accuracy

+1% of the upper limit of the test pressure value, -1% of the lower limit

Display accuracy

0.1 Bar

Test medium

Dry air

Pressure control method

Computer control

Boost rate

Adjustable, non-uniform linear

Pressure hold time

0-9999s arbitrarily set, with seconds as the time unit, computer display

Test process

Boost-hold-relief

Drive air pressure

0.2-0.8MPa

Volume size

Less than 10L

Water tank dimensions

Standard output Interface

Pressure curve display

Real-time display, data collected by software

Test data storage

Can save reports in excel form

Computer

Intel i5 4 G memory (or above) 512G SSD,Windows7 operating system and OFFICE processing software, with RS232 communication interface

Safety protection

Power

Leakage protection, overload and short circuit protection

Motor

Overload, short circuit protection

2. During the test, the sample must be placed in the water tank to prevent the explosion caused by the sample being unable to withstand the high pressure and causing unnecessary damage to personnel.

3. Release the pressure in the gas storage tank when it is not in use for a long time.

4. Regularly open the ball valve at the bottom of the gas storage tank to discharge the water in the gas storage tank.