Products

IEC60309-1 Cable Anchorage Pull Force And Torque Test Apparatus Test EV Charging Interface

Products Description

IEC60309-1 Cable Anchorage Pull Force And Torque Test Apparatus Test EV Charging Interface

Product Information:

This pull force and torque test equipment is used to test the vehicle plugs, and socket-outlets, connectors to withstand the specified pull force and torque.

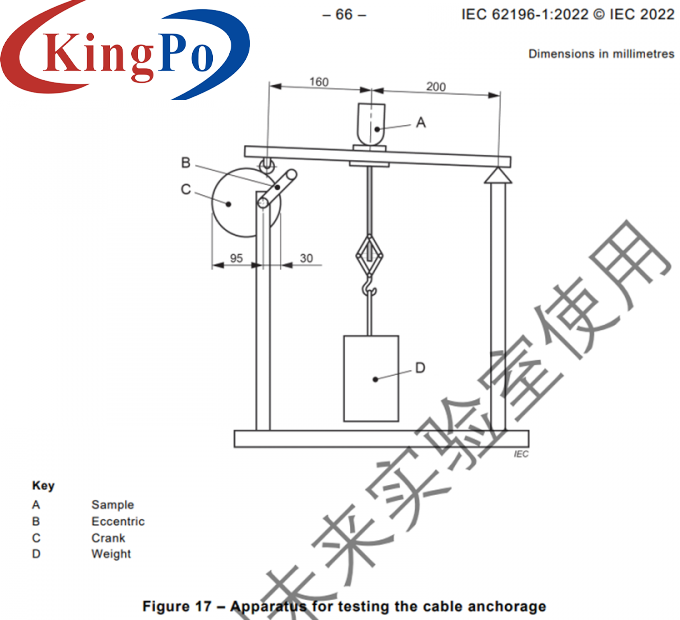

It is designed and manufactured according to IEC62196-1: 2020 clause 25.3 Figure 17 and table 11, IEC60309-1: 2012 clause 23.3, etc.

Samples and restrictions: electric vehicle charging interfaces, electric vehicle power equipment, industrial plugs and sockets and couplers.

Technical Parameters For Vehicle Plugs And Connectors Cable Anchorage Pull Force And Torque Test Apparatus:

50N, 60N, 110N, 1 each, 40N, 2 pcs, 100N, 3 pcs, can test 160N, 200N, 240N, 250N, 500N, 600N

0.1 N.m, 0.15 N.m, 0.20 N.m,, 0.25 N.m, 0.3 N.m, 0.35 N.m, 0.4 N.m, 0.425 N.m, 0.6 N.m, 0.7 N.m, 1.2 N.m, 1.5 N.m, 2.3 N.m, 11.0 N.m

Test purpose: used to test the ability of charging vehicle plug and socket connection cable accessories to withstand specified pulling force and torque.

Test principle: The pulling force is realized by using a single-phase speed-regulating motor to drive the eccentric mechanism. The motor speed is adjustable to ensure that the time of each pulling force is accurate. Torque is achieved using cylinders, pallets, weights and time relays.

Structure and features: Weights are used to apply tension, and the weights and torque arms achieve torque. Preset number counter and digital display time relay are used to control the number of times of pulling force and torque test time. The equipment will automatically stop when the number of tests or test time is reached. After the test, the maximum allowable displacement of the flexible cable of the charging gun connector shall not exceed the standard requirements.

Operation Method

PLC control

Drive Mode

Motor and cylinder

Tension schematic diagram

Pull Force Weights

Torque Weights

In addition, it complies with UL2594 Table 25: 0.41 N.m, 0.54 N.m, 0.68 N.m, 1.4 N.m, 2.7 N.m, 5.4 N.m, 10.8 N.m, 16.3 N.m, 22 N.m

Torque Arm

R100mm(Ф200mm)

Pull Frequency

1cycle/s

Pull Cycles

1-9999 cycles, can be preset, default 100 cycles

Torque Applied Time

0-99H59M59S, can be preset, default 1min

Fixture

One set of universal fixtures

Equipment Dimensions & Weight

W1600*D500*H1135mm, the whole machine is about 100Kg

Power Supply

Single phase AC220V±10%, 60Hz, 1KW