Products

IEC62196-1 Charging Interface Vehicle Rolling Test Machine

Products Description

A. Crushing force (5000±250) N

B. Crushing force (11000±550) N

(8±2) km/h for (5000±250) N test, we limit the speed to be max. 7 km/h, as above 7 km/h will loss the motor rapidly

0~5 km/h can be set for (11000±550) N test, suggest to set 2 km/h

ST225 / 75R15

2 pcs, one for (5000±250) N test, the other for (11000±550) N test

IEC62196-1:2014 Charging interface vehicle rolling test machine

Equipment Introduction:

This equipment puts the power supply plug and the vehicle plug with the cable recommended by the manufacturer on the concrete floor randomly, and applies (5000±250)N or (11000N±550)N to the car tires of the same load with the specification of P225/75R15. The pressure is rolled over the charging plug or plug function box (tire inflation pressure 2.2±0.1) Pa at a speed of (8±2)km/h to simulate and test the ability of the power plug or plug function box to withstand vehicle crushing damage .

It is used to carry out vehicle rolling test on the power supply plug and the vehicle plug of the charging vehicle to determine its reliability after being compressed.

Test Principle:

Accessories wired with the minimum size cable of a type recommended by the manufacturer shall be placed on a concrete floor in any normal position of rest. A crushing force of (5000±250) N or (11000±550) N shall be applied by a conventional automotive tire, P225/75R15 or an equivalent tire suitable for the load, mounted on a steel rim and inflated to a pressure of (2.2±0.1) bar. The wheel is to be rolled over the vehicle connector or plug at a speed of (8±2) km/h. The accessory is to be oriented in a natural resting position before applying the force in a different direction for each sample. The accessory under test shall be held or blocked in a fixed position so that it does not move substantially during the application of the applied force. In no case is the force to be applied to the projecting pins.

Technical Parameters:

Test Station

Single

Electrical Control Method

PLC intelligent integrated control, color humanized touch interface operation

Drive Mode

Motor driven

Load Carrying

Drive Over Speed

Roll Over Method

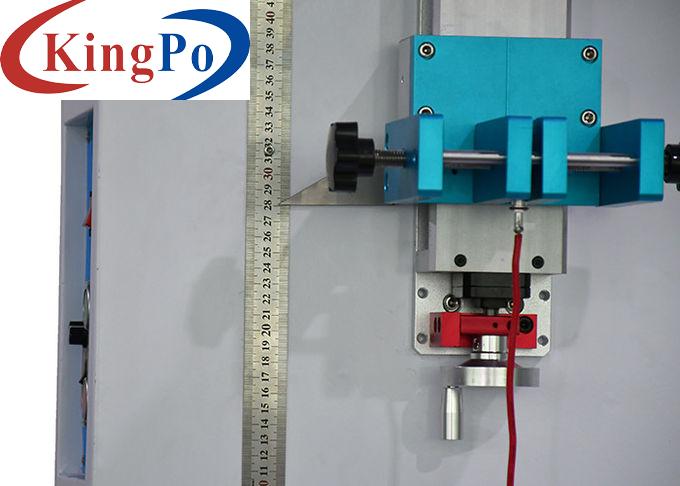

The linear motor module is used to drive the automotive tire to simulate the front and rear reciprocating rolling motion (to simulate the damage caused by the accidental rolling to the vehicle connector or plug during the forward or reverse moving of the car in the real scene)

Crushing Force Loading

Using supplementary weights to apply the crushing force

Drive Over Tire

Air Pressure of Tire

(2.2±0.1) bar

Test Floor

A bottom plate with cement/ concrete surface

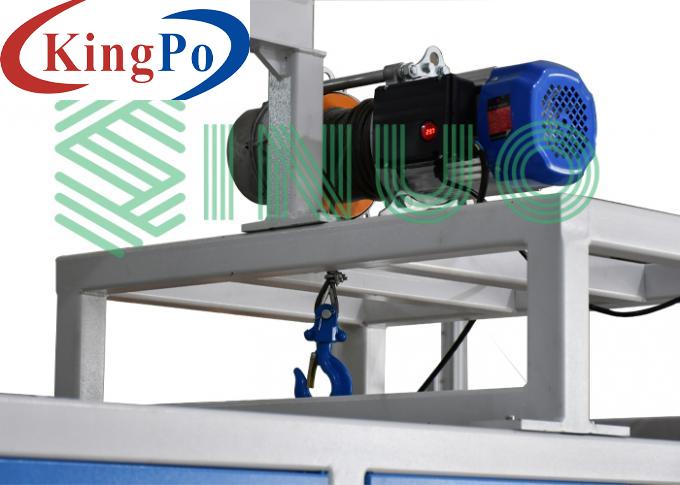

Lifting Device

Electric hoist

Tire Installation

Electric hoist lifting and restructuring

Driveover Speed

Can be display and set on the touch screen

Shock Absorption Method

Damping spring

Equipment Structure:

This equipment adopts servo motor to control speed, Mitsubishi PLC controller, with high control precision.