Products

IEC 62133-1 Chemical Battery Enclosure Pressure Test System With PLC Control

Products Description

IEC 60335-1 Chemical Battery Enclosure Pressure Test System With PLC Control

Product Overview For Battery Case Pressure Testing System:

Compliance with standards and clauses: IEC 60335-1:2020 - Annex BB-20.1.

Specimens and limitations: Containing monolithic cells using metal ion chemistry.

Test purpose: To measure the stress generated when the housing of a battery-powered device containing a monolithic cell using metal ion. Chemistry is subjected to the battery during a failure and to verify the housing strength of the battery housing.

Test principle: using the booster pump to increase pressure, through the pressure sensor connected to the pipeline real-time monitoring.

Structure For Battery Case Pressure Testing System:

The structure of the device is controlled by a touch screen, which can read out the pressure curve display, increase the gas capacity, test pressure, and test time can be set. The pneumatic booster pump and its pressure control device are used for stable performance, convenient operation and beautiful appearance. It integrates the advantages of many similar products at home and abroad, and is the first choice for major domestic measurement institutions and laboratories.

Technical Parameters For Battery Case Pressure Testing System:

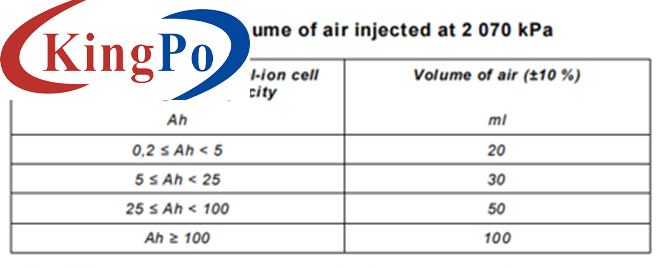

10-100ml is adjustable and can be realized (20, 30, 50, 100ml)

Test station

1 station

Control method

PLC control and touch screen operation

Drive mode

Booster pump driver

Test medium

Gas

Test pressure

0.01-2.5mpa, pressure sensor monitoring

Gas capacity

Test time

0-999999s can be set

Sealing joint

One set as standard, orifice Φ2.85±0.05mm

Test process

Manual loading and unloading test, automatic detection process

Use environment

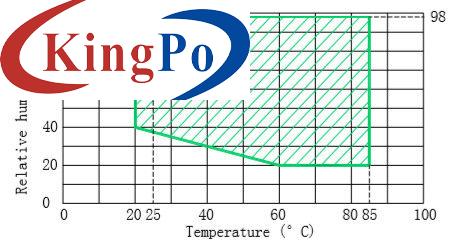

Atmospheric pressure 80~106kpa, ambient temperature 5~40°C, relative humidity (20~80) %RH, place of use: no violent shaking, vibration, no electromagnetic interference, no dust, no explosive and corrosive gases, good heat dissipation

Equipment size

About 1000×750×900 (mm) W×H×D

Equipment weight

110kg

Use environment

Power supply: AC220V±10%/50-60Hz, use environment: working temperature 0-40℃, humidity 30%-90%.