Products

IEC 62133-1 Digital Display Battery High Altitude Low Pressure Test Chamber

Products Description

Product information:

Ambient Temperature

Vacuum Rate

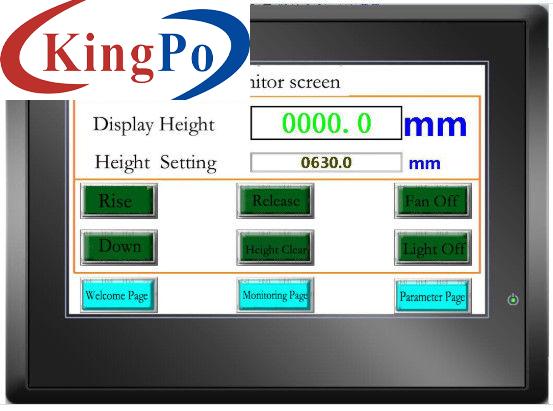

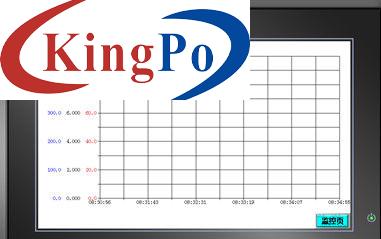

Touch Screen Monitoring

To judge the test result on condition of no explosion, flame, smoke, electric leakage after test. And the battery protection valve should not be broken.

Structure:

1 .Chamber adopt high quality cold rolled steel plate, surface with powder painted, with strong anti-rust ability.

IEC 62133-1 Digital Display Battery High Altitude Low Pressure Test Chamber

It conforms to IEC62133-1:2017 clause 7.3.7, IEC60086-4 clause 6.4.1, IEC 60086-1, UN 38.3, UL 1642, IEC61960, and etc.

Parameters:

Temp. Range

Note: When using, the internal temperature of the laboratory must be controlled to be (20°C+5°C) to reach the temperature requirement in the test box.

Display Method

Digital Display

Unit

Kpa

Internal Dimension

W600 X D600 X H600mm

Internal Material

SUS 304# Stainless Steel

External Dimension

W940 X D780 X H1620mm

External Material

SECC steel plate, power painted (thickness 1.5mm)

Bottom

Installed with universal wheel

Observation Window

Toughened glass with explosion - proof membrane

Timer

4 digits display 0~9999(Hour, Minutes, Seconds changeable)

Safety Devices1.3Kpa(standard requires 11.6Kpa, vacuum gauge indication value -89.7Kpa)

Remarks:as the inner chamber pressure is(101.325Kpa), if wants the inner chamber pressure decreased to 11.6Kpa. Calculating according to atmosphere pressure of(101.325Kpa), need to blow out (89.7Kpa) pressure of the inside chamber, then the inner chamber can reach low pressure environment of (11.6Kpa).

Pressure Range

0~100Kpa(Controllable, display)

Pressure Fluctuation

≤5%

Power Source

AC 220V 60HZ

Power

2.0KW

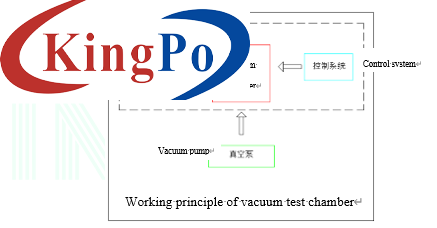

Working Principle

(use English))

2. Working room with high-quality stainless-steel plate, rounded shape, smooth, and easy for cleaning.

3. Between working room and chamber, filled with superfine glass fiber insulation material.

4. Chamber door with double toughened glass structure, available for clear observation of the inside chamber.

5. Installed rubber sealing ring between working room and glass door, ensure high vacuum rate inside the chamber.

6. Integrated type: low pressure chamber on upper side, and vacuum pump on bottom side.