Products

IEC 62133-2 Battery Testing Equipment 2017 Secondary Cells / Batteries Forced Internal Short Circuit Test

Products Description

IEC 62133-2 2017 Secondary Cells and Batteries Forced Internal Short Circuit Testing Equipment

External Chamber

External Chamber

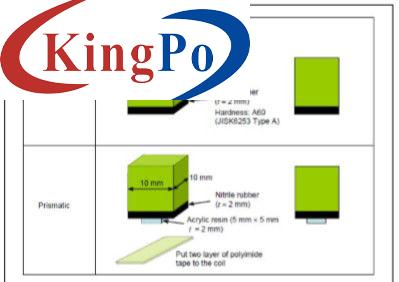

The thermal isolation layer up to100mm, which employs fire-resistance high density PU foam material and the

Single Door mountedwith3 layer vacuum glass viewing window with water-proof function (size: W430mm x H

On the left side of test chamber, attesting hole withitsdiameter50mm is opened with silicone rubber plug and

Imported silicone glue is applied for door frame and test chamber sealing to provide a reliable sealing

1.AirCoolingMethod: Fully Enclosed single-stage compressor

1.Heater: Naked-nichrome alloy electrical heater

1.Control Method: Programmable high accurate micro-computer controller: chilled-mirror dew-point hygrometer

Internal Short Circuit Chamber Main Technical Parameters:

1.Temperature Chamber& Servo control system1set

2. Brand Computer: 19 inch LCD monitor,Yonah™2,dual core, 2GB DDR2,320GB /1set

3. Computer Rack/1set

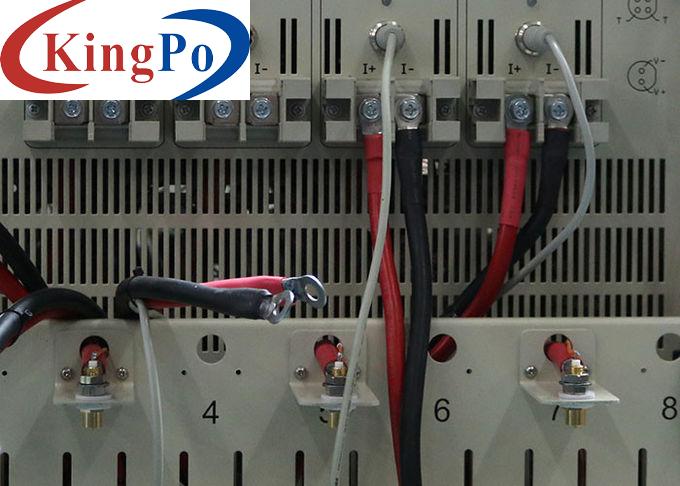

4. Voltage Acquisition system 1set

5. Servo Control software

6. Block5X5MM 1pcs,10X10MM 1pcs(additional5x5 mm(+5Pcs) , 10x10 mm(+5Pcs) nitrile rubber)

7.

8. Pressure Sensing System1set

9. Smoke exhaust system 1Set

Overview:

This battery forced internal short-circuit tester is an integral testing equipment to performance a comprehensive test for temperature, voltage, internal-short circuit, which is applicable for battery cell safety test.

The battery is placed between crush boards, oil cylinder apply force to battery through piston, when system reach the setting value or voltage reach these setting value, system release pressure and return.

Standard Compliant:

It conforms to IEC 62133-2012.8.3.9., IEC 62133-2:2017 clause 7.3.9, JISC8714:2007 5.5, and etc.

Feature:

1. Fullycomputerized, comprehensive testing force, deformation, voltage parameters;

2. Electrohydraulic servo drive, force, displacement, voltage display on same interface.

3. Innerbuilt sensor, not influence by outer environment;

4. Force sensor located on top of the cylinder, not influenced by inner temperature, higher accuracy;

5. Internal chamber designed as mirror stainless steel with viewing window, door lamp, air-blower as well as universal wheels that easy to move

6. Computer control method to pre-set all parameters with excellent appearance and real-time monitoring.

Temperature Chamber Technical Parameters:

Temperature Range

-20℃ ~ +100℃(Controllable)

Resolution

0.01℃

Temperature Fluctuation

0.5℃

Temperature Uniformity

2.0℃

Max. Low Temperature

-5℃

Temperature Rising Rate

Ave.3℃/min(0℃ to100℃,Nonlinear No-load)

Temperature Cooling Rate

Ave.1℃/min(100℃to0℃,Nonlinear No-load)

Inner Chamber Dimension

W600 X H750 X D500MM

Inner Chamber Material

Mirror stainless steel with bottom reinforcement

DimensionW1500mm*D1000mm*H1750mm

MaterialCold-Rolled Steel with paint-baking treatment (gray-white color)

Insulation Layer

thermal isolation coefficient less than0.0212kcal/m∙hr.

Chamber Door

Single Door, Overall Size: 500×750mm

Observation Window

580mm), the door framed signed with electrical heating function (automatic adjustment) to proof frost, dew,

thus, provide the user a clear vision to observe entire testing process;

Testing Hole

Stainless steel cap/2pcs;

Sealing

performance;

Internal Lighting

Viewing window with 9WPhilipis LED lamp with energy-saving and moisture and explosion proof function

Refrigeration System

2.Compressor: FranceTecumsehCompressor1 set

3.Coolant: fluoride-free environmental coolant (USA DuPont) HFCR404A

4.Condenser: Air-cold highly efficient forced exchange fin type

5.Vaporizer: highly efficient multi-stage vaporizer with Hydrophilic membrane fin (thicker fin type)

6.Oil Separator: EMERSON

7.Vaporizer Pressure Regulator: Danfoss vaporizer pressure regulator (available to work in low temperature and

High humidity condition without no frosting)

8.Solenoidvalve: Japan saginomiya or Danfoss;

Heating System

2. Control Method: signal output from controller through the SSR to gain a high precise non-contact switching

control

Control System

To control temperature and humidity system. Anti-windup PID, BTC control method (thermal compensation

function) +DDC intelligent cool flow control+ DEC intelligent electrical control (temperature test alternative

testing program setting)

2.TEMI 880 color touchscreen controller to display temperature and humidity with EN menu. And 3.1’’LCD

controller is compatible with computer control.

Max. Loading

200KG

Resolution

1/10000

Force Accuracy

≤0.5%

Force Magnification

7-stageautomatic shift

Displacement Resolution

1/1000

Displacement Accuracy

≤0.5%

Speed Range

0.01-20MM/S

Effective Range

0~ 150mm

Max. Testing Plane

300X300MM (Available to custom design to meet special test)

Voltage Acquisition Range

0~20V

Voltage Resolution

1mV

Voltage Acquisition Frequency

100Hz

Power Source

220V 60HZ

Standard Configuration: