Products

UL486A-B Conductors Damage Degree Test Machine For Checking Damage Degree Of Wire 2 Stations

Products Description

UL486A-B Conductors Damage Degree Test Machine For Checking Damage Degree Of Wire 2 Stations

Product Introductions:

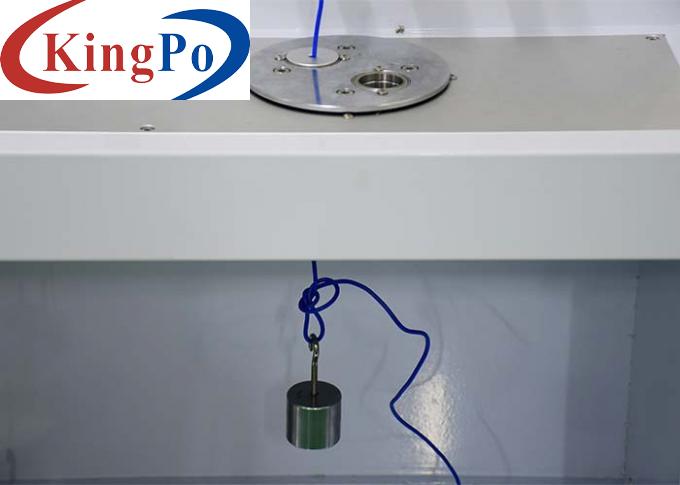

This conductors damage degree testing machine is also called the test apparatus for checking damage degree of wire which confirms to standards UL486A-486B and UL498 SD5.3 test method B, etc. This test machine is used for judging whether the design and the structure of the clamping screw terminal is correspondent with the requirement of non over-damage to the wire. Besides, it is also used to check whether the clamping screw terminal can bear the stress during the process of normal usage.

The testing times can be preset before the test, and the testing machine stops automatically with the alarm when the testing times are reached.

Principle:

Used to examine whether screw-type terminals and screwless terminals can withstand the mechanical stress that occurs during normal use. It is mainly used to determine whether the design and structure of the screw clamping terminals meet the requirements of not excessively damaging the wires when they clamp the wires.

Technical Parameters:

The tensile force of the conductor test is as follows:

If the diameter of the sleeve hole is not large enough, the wires must be bundled to be inserted into the sleeve hole. Users can use a larger size sleeve instead.

Distance (H) deviation ±15mm

Power supply

AC 220V±10V, 60Hz

Standards

UL498, UL486A-B, IEC 60884-1, etc.

Stations

Two stations, synchronization

Test speed

10±2 r/min, 9±1 r/min

Weights

0.3, 0.4, 0.7, 0.9, 1.4, 2kg

Gyration Diameter

75mm/76mm

Test height

25-600mm, can be adjustable

Test times

0-999999, can be preset

Bushing holes

Diameter: 6.5mm, 9.5mm,13mm,14.5mm

Nominal cross section of conductor mm²

Casing hole diameter mm

Distance (H) mm

Weight corresponding to the conductor (Kg)

0.5

6.5

260

0.3

0.75

6.5

260

0.4

1.0

6.5

260

0.4

1.5

6.5

260

0.4

2.5

9.5

280

0.7

4.0

9.5

280

0.9

6.0

9.5

280

1.4

10.0

9.5

280

2.0