Products

IEC 60884-1 Figure 15 Connections Of Conductors Pull Force Test Apparatus For Socket Test

Products Description

IEC 60884-1 Figure 15 Connections Of Conductors Pull Force Test Apparatus For Socket Test

Product Information:

This test apparatus conforms to IEC 60884-1:2022 clause 13.4 figure 15. It is used to detect the socket structure of the screwless terminal during or after the socket is installed on the installation box or wall, the connection and/or disconnection device of the screwless terminal cannot be triggered by the conductor, and the safety performance of its structure is verified.

Test principle: Use the push rod connection test tool 1 (Ф50 steel ball) to apply a 120N push force to the connection and/or disconnection device. After the force value is reached, set a release weight to apply a 30N pull force to the conductor, and take it off after 1 minute of the test time.

Technical Parameters:

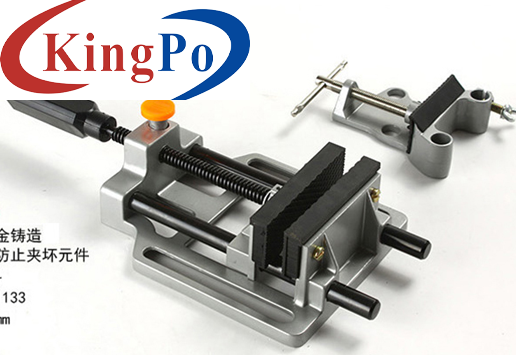

Multifunctional open flat pliers, adjustable up and down, left and right

Test station

One station

Electrical control method

Intelligent integrated control of electrical appliances, digital display chronograph, digital display force value meter view

Drive mode

Motor drive + hand sliding table

Test items

Wire connection tension test (including 120N push force and 30N pull force)

Test process

Drive the force-applying steel ball along the sliding table to apply thrust to the sample by shaking the hand wheel. When the digital display shows that the force value reaches 120N, the equipment automatically drives the motor and the cam structure to separate the weight tray from the 30N tension weight. Gently apply tension to the wire, and the weight tray will automatically reset after 1 minute, stop applying tension, and manually shake the handwheel in the opposite direction, the steel ball will be separated from the sample, and the test is over

Sample clamping method

Force steel ball

SФ50+0.05 mm

Thrust exert method

Manually, drive the force-applying steel ball along the slide table to apply thrust to the sample by shaking the hand wheel, the digital display will display the force value, and automatically apply the pulling force when the force value is reached

Thrust sensor

0-200N, resolution 0.1N

Pull weight

30N

Tension exert method

Motor-driven cam releases weight tray from tension weights

Tension exert time

0-9999S, set the digital display chronograph, the device will automatically start timing and reset

Arrangement of force exert

The structure of double sliding table ensures that the test sample 1 does not touch the wire when the force is applied

Result judgment

Whether the wire comes out of the screwless terminal when the pulling force is applied, if it comes out, it is unqualified

Equipment size and weight

About: 800×800×1100 (mm) W×D×H, equipment weight about: 100kg