Products

Spring Hammer Test Apparatus 5J For Mechanical Strength Verification IEC 60068-2-75

Products Description

Spring Hammer Test Apparatus 5J For Mechanical Strength Verification IEC 60068-2-75

Product information:

Standard: IEC60598-2-3, IEC62262:2002, IEC 60068-2-63, IEC 60068-2-75 test Ehb, etc.

Sample and restrictions: Doors of column type composite lamps

Feature:

A spring hammer test apparatus, also known as a spring-operated impact hammer, is a specialized testing instrument used to perform impact tests on electrical equipment and enclosures. It is designed to simulate mechanical impact conditions that may occur during transportation, installation, or everyday use. The apparatus consists of the following components:

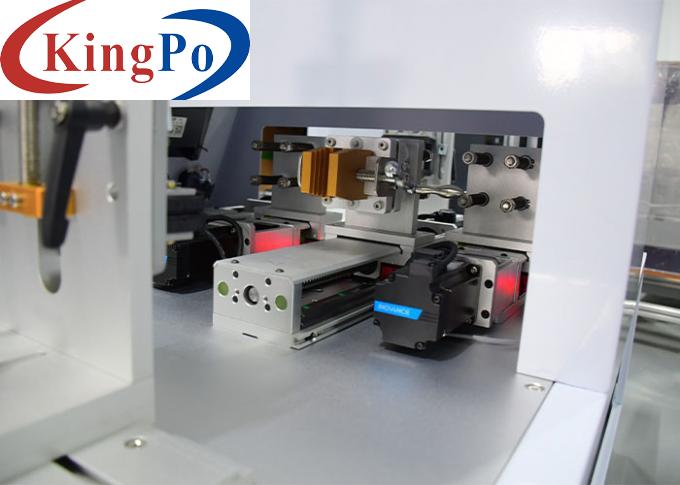

Spring Hammer: The core component of the apparatus is the spring-operated hammer. It typically consists of a metal body with a striking element attached to one end. The hammer is propelled by a compressed spring mechanism that stores potential energy. When released, the spring rapidly drives the striking element to impact the test sample.

Structure:

The impact hammer is composed of three parts:

A. Shell. Includes housing, impact element guide and release mechanism, and parts fixed on these parts.

B. Impact element. Including the hammer, hammer tail and firing handle.

C. Release cone.

Technical parameters:

Model

SN2207-5.0

Impact energy(J)

5 N.m, accuracy ±5%

Combined mass

1700g, accuracy ±2%

Material

Stainless steel

Notice:

1. After calibrating the device, don’t disassemble it or adjust the compression amount of the spring.

2. If the compression amount of the springs is adjusted, the device must be checked by the measurement department before being used. Otherwise, the accuracy of testing results will be directly influenced.

3. In order to prevent changes of impact energy caused by misoperation, the products have been sealed in the factory. If you have any question, please contact our factory, we will provide you post-technical services.

4. Measures should be taken to prevent the rust of the hammer spring (drying moisture proof processing).

5. Requirements for environmental conditions: temperature 5~35℃, humidity 45 ~ 75%.

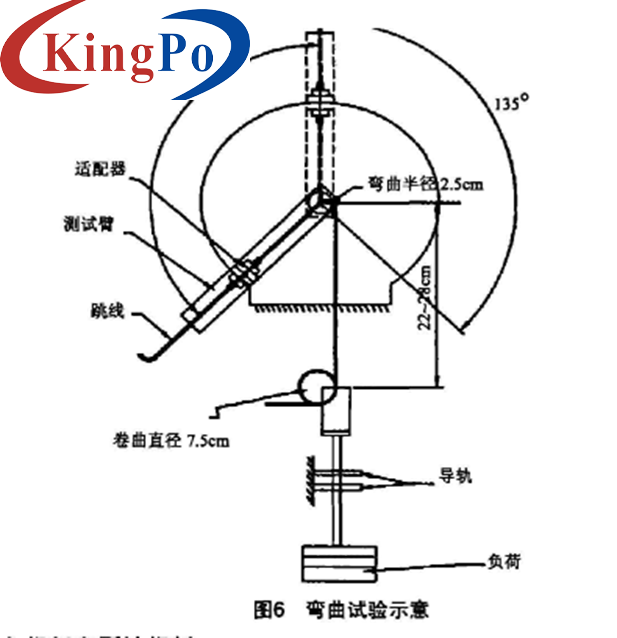

Test purpose: Used to test the impact resistance of the surface of the door of column type composite lamps, and evaluate the safety performance and strength level of the product

Test principle: The spring impact hammer mainly generates standard energy through the standard mass of each component and the movement of the hammer spring. When the operating handle is pulled, the release claw falls on the release point of the impact component. The hammer spring is compressed, and when the compression amount is different, the spring will release different energies. The multi-speed impact hammer knob end cover can select the corresponding energy.

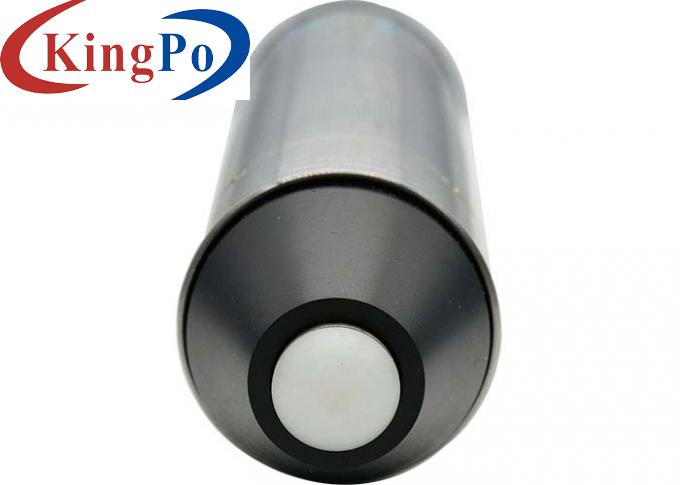

Striking Element: The striking element is the part of the spring hammer that comes into contact with the test sample. It is usually made of hardened steel and has a specified shape and size, depending on the testing standards or requirements. The shape of the striking element can vary, such as a sphere, a cylindrical tip, or a flat end, depending on the intended application and test specification.

Release Mechanism: The spring hammer apparatus incorporates a mechanism to control and release the stored energy in the spring. This mechanism ensures consistent and repeatable impacts during the testing process. It may include a trigger or lever that, when activated, releases the spring and initiates the impact.

Energy Adjustment: Some spring hammer test apparatus models allow for the adjustment of the impact energy. This feature enables the user to select different energy levels based on the testing requirements or relevant standards. Energy adjustment is typically achieved by adjusting the tension of the spring or by selecting different springs with varying stiffness.

Calibration Mechanism: To maintain accurate and reliable test results, spring hammer test apparatus often include a calibration mechanism. This mechanism allows for periodic verification and adjustment of the impact energy, ensuring that the apparatus remains within the specified tolerance limits.

Safety Features: Safety is a crucial consideration in the design of spring hammer test apparatus. These may include safety enclosures or shields to prevent accidental contact with the striking element, as well as safety interlocks or guards to protect operators during the testing process.

When conducting tests using a spring hammer test apparatus, it is essential to follow the relevant testing standards, such as IEC 60068-2-75 or EN 60068-2-75, which provide specific test procedures, impact energies, and acceptance criteria. It is also important to adhere to proper safety guidelines and manufacturer instructions to ensure safe and accurate testing procedures.