Products

IEC 61058-1 Household Appliances couplers Endurance Test System

Products Description

IEC 61058-1 Household Appliances Couplers Endurance Test System

Standards & Clauses:

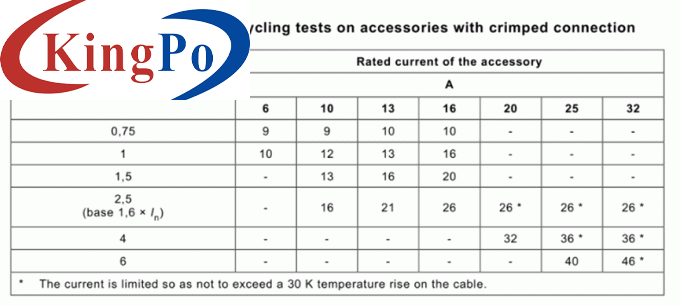

IEC61058-1:2008 “Switches for appliances Part1: General requirements” clause 17

IEC60884-1:2006 “Plugs and socket-outlets for household and similar purposes- Part1: General requirements” clause 20 and 21

IEC60669-1:2007 “Switches for household and similar fixed-electrical installations - Part1: General requirements” clause 18 and 19

IEC60320-1:2007 “Appliance couplers for household and similar general purposes- Part1: General requirements” clause 19 and 20.

Purpose, principle and structure of system

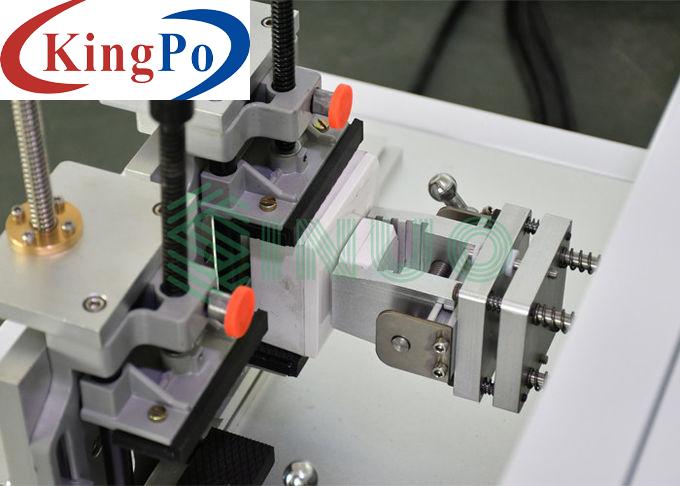

This endurance tester is used for switches, plugs and sockets, couplers for household and similar fixed electrical installations to making and breaking capacity and normal operating life. To assess whether switches, plugs and sockets can withstand mechanical damage and electrical fatigue damage during normal use, and whether there is contact adhesion or long-term closing or disconnecting, and inspect them for excessive wear and other harmful consequences is a special equipment for electrical durability test of switches and plugs and sockets. The equipment can do rocker switch / boat shape switch, push button switch, toggle switch and plug and socket life test. With the load (resistive, inductive, capacitive), the load test can be done, and there is a corresponding control system.

The equipment adopts advanced PLC intelligent control system and touch screen user-friendly operation interface, which makes the recording and display more accurate; the test times, test frequency and test stroke can be preset, and it can detect the current on and off. The 3-station on both sides of the whole machine can be used for linear switch test or plug and socket test synchronously. When the switch is continuously connected or disconnected due to adhesion or failure, it can alarm and record the corresponding number of experiments. When the set number of times is reached, it can alarm; when an alarm occurs, the experiment will be automatically stopped. The box body is beautiful in appearance; it integrates many advantages of similar products at home and abroad, with stable performance and convenient operation. It is the first choice for major measurement institutions and laboratories.

Technical Parameters:

Every Other Output Function

This tester has function: Every other output function, which is mainly used in the plug and socket test. After the load current is connected and the current detection function is turned on, when the plug is inserted into the socket for the first time, the program controls the current of the load cabinet to flow through the socket, and then closes the load cabinet after pulling it out. When the plug is inserted into the socket for the second time, no current flows through the socket, there is current for the third time, and there is no current for the fourth time. In this cycle, the purpose of intermittent power-on is achieved.

Test Projects

Warning

Safety Instructions

No.

Project

Parameter

1

Power supply

AC 220v±10%/50hz

2

Station

6 station linear

3

Operation interface

7-inch color LCD touch screen

4

Drive mode

Servo motor

5

Control system

PLC control

6

Test count

0~999999 times, can be preset

7

Current time

0~999.9s, can be preset

8

Disconnect time

0~999.9s, can be preset

11

Test stroke

Linear: 0~150mm, can be preset

12

Test speed

Linear: 0~200mm/s, can be preset

13

Test environment

Atmospheric pressure 80~106kpa; Ambient temperature 5~40°C; Relative humidity (20~90)%RH; Use place: no violent shaking, vibration, electromagnetic interference, dust, explosive and corrosive gas, good heat dissipation

Please read the product instruction manual carefully before using the equipment, master the knowledge of electricity safety, and take corresponding safety precautions; this test can be carried out only when it is confirmed that there is no potential safety hazard.

The voltage passing through the sample is 1.1 times the rated voltage of the sample, and the current passing through the sample is 1.25 times the rated current value of the sample. Please select the voltage and current value according to the standard, otherwise it will cause damage to the sample and accidents that endanger personal safety.

Please ensure that the wire connecting the sample switch to the load is compatible with the allowable rated current of the sample switch.

During the test work process, please observe the operator carefully and do not leave the operation post.

The wiring of the terminal on the rear panel of the instrument should be in reliable contact and ensure good insulation.

After power on, do not touch the terminal on the rear panel of the instrument to prevent electric shock.

When replacing the fuse, remember to cut off the power supply before you can replace it with a fuse of the same capacity.