Products

IEC 60884-1 Clause 24.3 Rigid Steel Sheet Test Cylinder For Socket - Outlet Torque Test

Products Description

IEC 60884-1 Clause 24.3 Rigid Steel Sheet Test Cylinder for Socket-outlet Torque Test

Product information:

The test cylinder meets the requirements of IEC 60884-1 2013 clause 24.3, IEC 60669-1 clause 20.2. It is used to check the reliability of the fixed structure of surface type sockets.

Equipment characteristics:

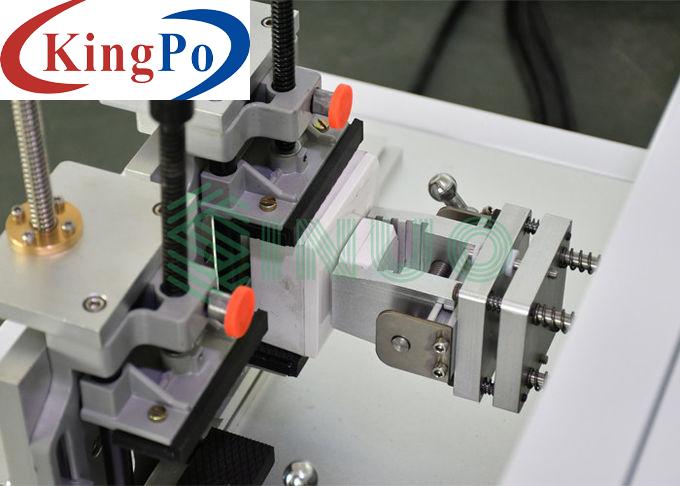

This device is processed by treated steel tube, use to check the mechanical strength of the surface type sockets.

Technical parameters:

Test procedures:

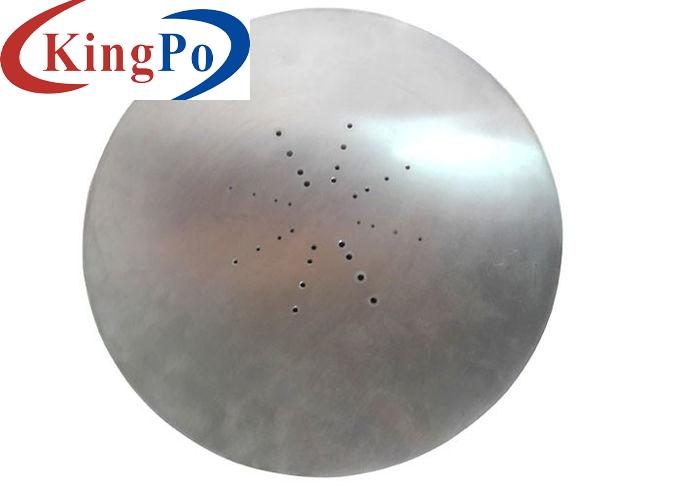

The bases of surface type socket-outlets are first fixed to a cylinder of rigid steel sheet, having a radius equal to 4.5 times the distance between fixing holes but, in any case, no less then 200mm. The axes of the holes are in a plane perpendicular to the axis of the cylinder and parallel to the radius through the centre of the distance between the holes.

The fixing screws of the base are gradually tightened, the maximum torque applied being 0.5 Nm for screws having a thread diameter up to and including 3mm and 1.2 Nm for screws having larger thread diameter.

The bases of socket-outlets are then fixed in a similar manner to a flat steel sheet.

During and after the tests, the bases of socket-outlets shall show no damage impairing their further use.

Radius of cylinder

>200mm, equal to 4.5 times the distance between fixing holes

Cylinder height

>200mm

Cylinder thickness

>3mm

Cylinder material

processed by treated steel tube

Mounting holes

equipped with type 86 mounting holes, type 118, type 120 mounting holes or other types are optional

Conforms to standard

IEC 60884-1 2013 clause 24.3, IEC 60669-1 clause 20.2