Products

IEC 60884 13A Plugs Insulation Sleeve Wear Resistance Tester 4N Force

Products Description

IEC 60884 13A Plugs Insulation Sleeve Wear Resistance Tester 4N Force

Standards

Performance

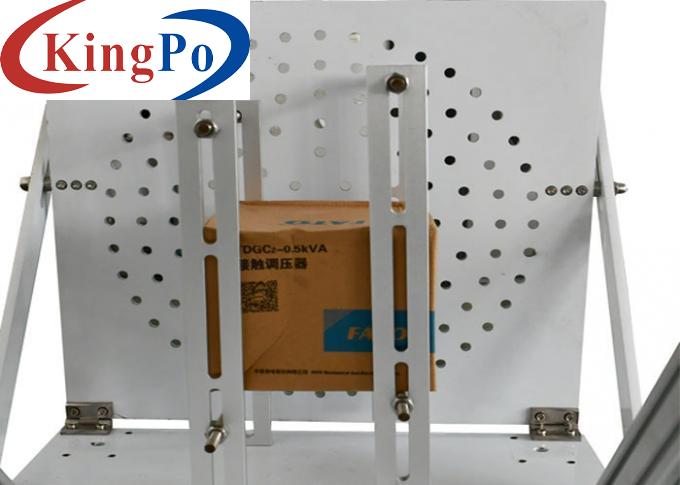

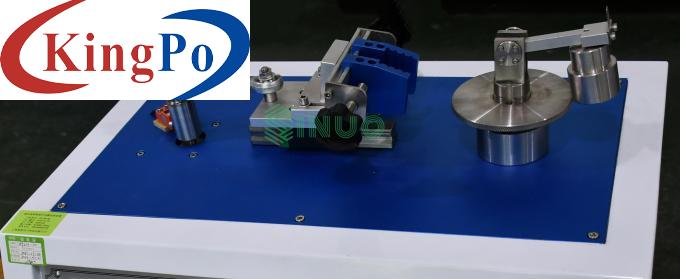

The scraping frequency of this test device is 30 times per minute, and the return and return are recorded as one time respectively. The number of tests can reach 0-999999 times, the number of tests can be adjusted and set. The working stroke is 9mm, and the scraped insulation sleeve is 7mm. The pressure load is 4N, the diameter of the scraper wire is 1mm, and the effective length is 6mm

Structure

It consists of a horizontal beam and a fixture seat with linear movement. The end of the beam is equipped with a U-shaped head bent by a short steel wire with a diameter of 1mm (the two points of the U-shaped are fixed vertically on the beam). The u-shaped bottom edge of the steel wire is a 6mm straight working part. The U type steel wire 6mm straight bottom edge is pressed on the insulation sleeve of the bolt, and the motor drives the fixture seat with the bolt to do reciprocating movement, so that the friction between the steel wire and the insulation sample of the bolt is tested.

Sample range, use, principle, structure and use environment

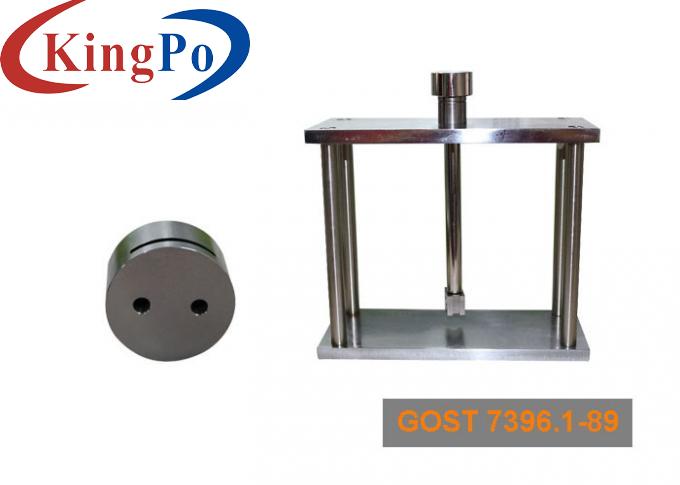

IEC 60884-1:2006 "Plugs and sockets -outlets for household and similar purposes- Part1:General requirements" clause 24.7 and figure 28.

BS 1363-1-2012 "13A Plugs, Socket-outlets, Adaptors and Connection Units Part1:Specification for Rewirable and non-Rewirable 13A plugs figure 9.

Samples and Restrictions

Insulation sheath for plug pin

Test purposes

It is suitable for testing the wear resistance of insulation sleeve of plug pin

The test principle of

Using motor drive eccentric mechanism to achieve the reciprocating scraping of the latch jacket

Equipment structure and characteristics

It consists of a horizontal beam and a fixture seat with linear movement. The end of the beam is equipped with a U-shaped head bent by a short steel wire with a diameter of 1mm (the two points of the U-shaped are fixed vertically on the beam). The u-shaped bottom edge of the steel wire is a 6mm straight working part. The U type steel wire 6mm straight bottom edge is pressed on the insulation sleeve of the bolt, and the motor drives the fixture seat with the bolt to do reciprocating movement, so that the friction between the steel wire and the insulation sample of the bolt is tested. Equipment dimensions: about 600×600×500 (mm) W×D×H, equipment weight: 70kg

Using the environment

Power supply: AC220V±10%/50-60Hz, working temperature 0-40℃ humidity 30%-90%;