Products

IEC61009-1 Circuit Breaker Mechanical Shock Tester Touch Screen Control

Products Description

IEC61009-1 Circuit Breaker Mechanical Shock Tester Touch Screen Control

Product overview

The mechanical shock test equipment is based on the relevant requirements of IEC60898-1, IEC61009-1, IEC60934:2007.

Equipment principle

Overview of the test process

Main Teachnical Parameter

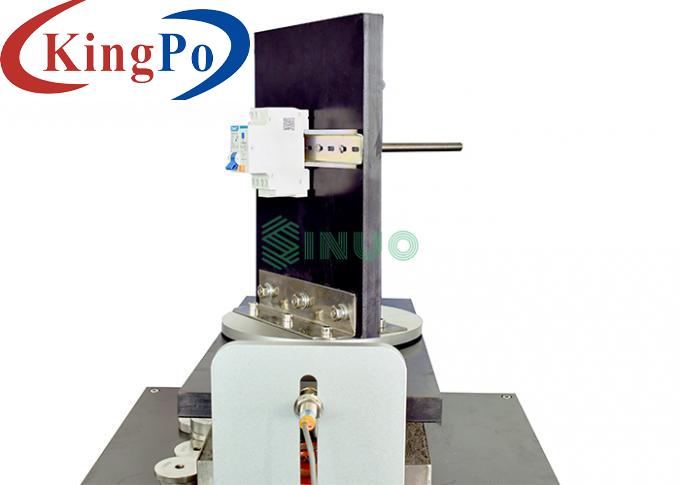

Design and manufacture, suitable for circuit breaker products, to verify the impact resistance of exposed parts that may be subjected to mechanical shock during normal use of the circuit breaker.

The equipment adopts PLC control, touch screen operation, motor-driven cam mechanism to control the lifting action, the interval time can be preset, the whole machine adopts a floor-standing structure, easy to operate, practical and beautiful.

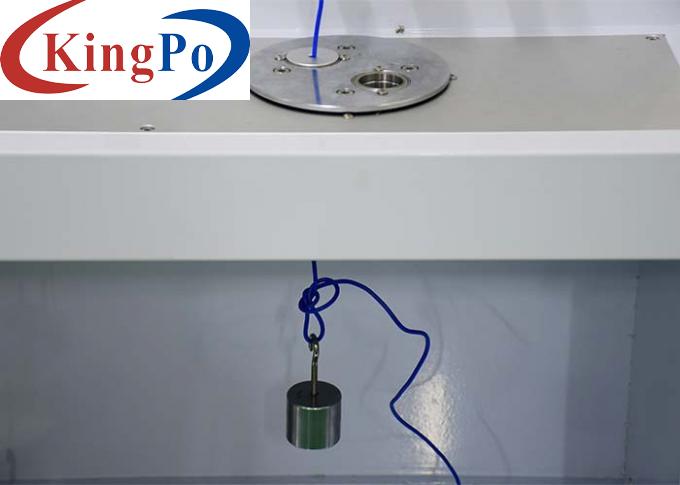

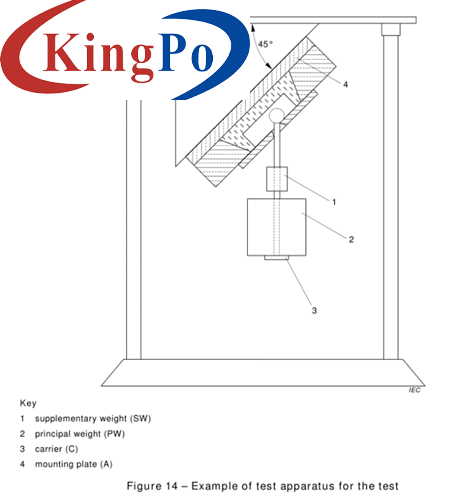

Designed in accordance with IEC60898-1, the mounting plate equipped with the circuit breaker is lifted by the motor control cam, and instantly falls freely to the metal stop plate equipped with a spiral spring with an elastic coefficient of 25N/mm. This reciprocating 50 times, the sample is switched to another 3 90-degree directions through the turntable to repeat the test 50 times.

1. Fix the test product on the front of the vertical plate, make the test product in the closed position, but do not connect any power, press the touch screen to reset, the working platform rises to the initial state of the free end, and the counterweight is applied to the opposite side of the sample mounting plate. The helical spring is compressed by 1mm (that is, the force acting on the metal stop plate is 25N at this time).

2. Press the start button on the touch screen, the free end of the working plane will automatically rise to a height of 40mm and fall, record the time of the sample from vibrating to standstill, and set the fall time to be greater than this standstill time. Set the number of drops to 50 times. Then press start again, the sample will fall back and forth 50 times automatically

3. Rotate the turntable by 180° and repeat the drop test 50 times.

4. Rotate the turntable by 90° and repeat the drop test 50 times.

5. Rotate the turntable by 180° and repeat the drop test 50 times.

6. Other angle tests can be freely selected

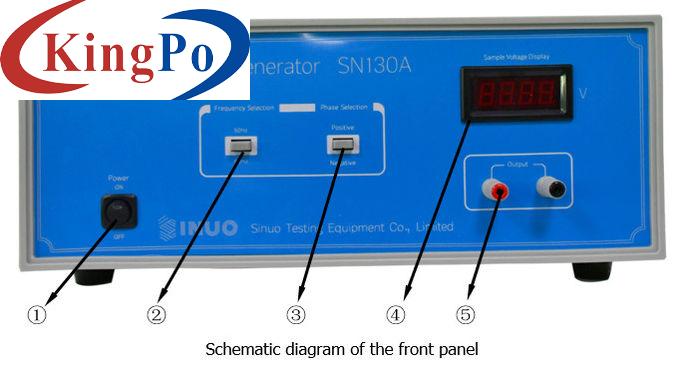

Control mode

PLC control, 7-inch touch screen operation

Drive

Servo motor and cam drive

Helical spring

Elastic coefficient 25N/mm

Drop height

40mm

Turntable

It can be rotated and fixed at 12-30°

Counterweight

100g*10, 150g*5, 200g*5

Test count

0-999999 times, touch screen preset

Interval time

0-999999 seconds, touch screen preset