Products

IEC 60529 IP Code IPX1 ~ 4 Degrees Of Protection Test Chamber 1400L

Products Description

IEC 60529 IP Code Protection Degrees Comprehensive IPX1~4 Test Chamber

Product introduction

The waterproof degree test chamber is designed and manufactured according to requirements of IEC 60529: 2013 IPX1, IPX2, IPX3 and IPX4. It is used for testing electronic and electrical products, lamps, electric cabinets, electrical components, automobiles, motorcycles and their parts and components’ physical and other related properties under simulated climatic conditions. After the test, it is judged whether the performance of the product meets the requirements, so as to facilitate the design, improvement, verification and factory inspection of the product.

Technical Parameters:

IPX1 turntable parallel

IPX2 can achieve 15° by adding the incline device on the turntable

IPX3/4 turntable can rotation 360°

1 +0.5 0mm/min(IPX1)

3 +0.5 0mm/min(IPX2)

±60° (IPX3),

approximately ±160°(IPX4)

(Note: standard requires IPX3:120°; IPX4:360°, but due to there is turntable under oscillating tube during test, so 360° can not achieved during actual testing, if without turntable, then 360° can be achieved)

120°(IP3)

180°(IP4)

Nozzle Holes

121 holes of Ф0.5mm

1 hole at the centre

1 inner circles of 12 holes at 30° pitch

4 outer circles of 24 holes at 15° pitch

Model

SN4413-1400

Inner Chamber

1400mm*1400mm*1400mm

Outer Chamber

Approx. 1900mm*1560mm*2400mm

Outer Chamber Material

Spray treatment, concise, beautiful and smooth

Inner Chamber Material

High quality stainless steel plate

Weight

Approx.300KG

Turntable

Rotating Speed

1 ~5 rpm adjustable

Turntable Diameter

600mm

Turntable Height

Adjustable height: 200mm

Turntable Bearing Capacity

Max. 20KG

Turntable Function

IPX1/2 Dripping

Dripping Hole Diameter

φ0.4 mm

Dripping Aperture Spacing

20 mm

IPX1, IPX2 Dripping speed (water flow)

Dripping Area

1000X1000 mm

Distance between Drip Box and Sample

200 mm

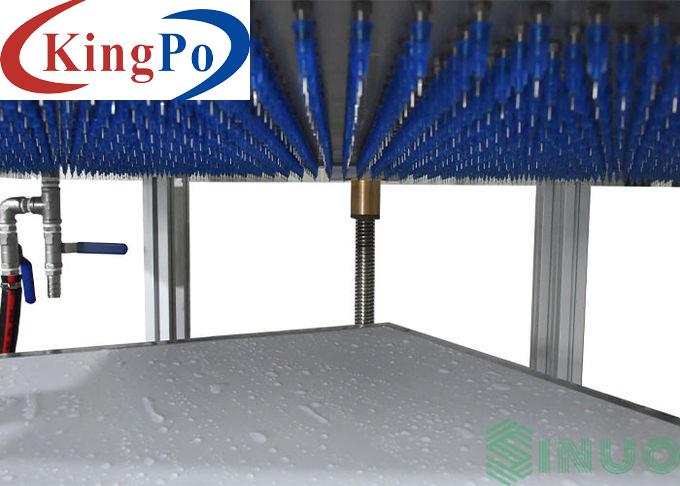

IPX3/4 Oscillating Tube

Oscillation Tube

R600 mm

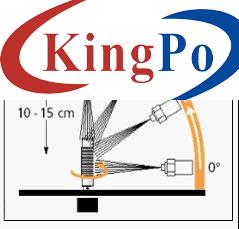

Distance between Nozzle Sample

Within 200mm

Spray Aperture Spacing

50 mm

Oscillating Tube Swing Angle

Angle Between Two Holes

Needle Hole

φ0 .4 mm

Oscillating Speed

IPX3: 15times/min; IPX4: 5times/min

Water Flow of Each Hole

0.07 L/min +5%

Spray Pressure

80-150Kpa

IPX3/4 Spray Nozzle

Water Flow

10L(min)

Spray Nozzle Spherical Diameter

102 mm

Moving Shield Material

Stainless steel

Spray Nozzle Material

Brass

Handle and Valve Material

304 stainless steel

Configured Pressure Gauge

0~0.6MPa

Water Spray Pressure

50~150(kpa)

Electrical Control

Controller

LCD touch controller

Test Time

1-999,999min (can be set)

Turntable Control

Reduced motor, speed is stable

Oscillating Control

Stepping motor, oscillating tube swings stable

Flow and Pressure Control

Use manual valve to control flow and pressure, glass rotameters to indicate flow, stainless steel case spring pressure gauge to indicate pressure

Use Environment

Ambient temperature

RT10~35℃ (average temperature within 24H≤28℃)

Environment humidity

≤85%RH

Power supply

220V 50HZ single-phase three-wire + protective ground wire, the grounding resistance of the protective ground wire is less than 4Ω; the user is required to configure an air or power switch with corresponding capacity for the equipment at the installation site, and this switch must be independent and dedicated for the use of this equipment

Power

Approx. 3KW

Protection System

Leakage, short circuit, water shortage, motor overheating protection, alarm prompt