Products

IEC 60598-1 Cu and Zn Test Chain Short-circuit Protection for SELV Parts Temperature Rising Testing

Products Description

IEC 60598-1 Cu and Zn Test Chain Short-circuit Protection for SELV Parts Temperature Rising Testing

Standards & Clauses:

IEC 60598-1:2014 “Luminaries-Part1: General requirements and tests” clause 4.26 and figure 29

Samples and Restrictions:

Luminaires uninsulated accessible SELV parts of opposite polarity

Application:

Used to process unintended short-circuiting temperature rising testing for uninsulated accessible SELV parts of opposite polarity, to verify there are adequate means is provided to prevent the impairing safety.

Test Principle:

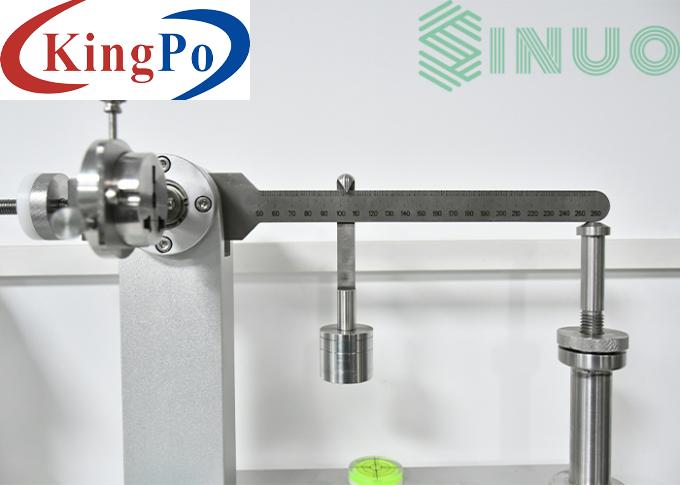

The test chain of sufficient length of an uncoated metal, having links and made of 63% Cu / 37% Zn, and having a resistance value of 2.5 Ω/m ±20% when stretched with a load of 200 g/m, cooperates with load test, to achieve the short-circuiting temperature rising testing for uninsulated accessible SELV parts of opposite polarity

Structure:

Made of 63% Cu / 37% Zn

Technical Parameters:

1. The resistance value of test chain should be checked before each measurement, to ensure the resistance value to be 2.5 Ω/m ±20% when stretched with a load of 200 g/m.

2. Measure the distance of the spacing between the polarities of the SELV parts, mark X, unit: cm.

3. Put the test chain on specimen, weights=15×X or maximum weight 250g should be hanged on each end of the test chain.

4. A thermocouple is placed at the appropriate position of the test sample and connected to the temperature measurement device.

5. Access 0.9-1.1 times of rated voltage to test sample.

6. Monitor that the test chain shall not melt through, or shall any part of the type test sample reach a temperature exceeding standard required value (refer to IEC 60598-1:2014 tables 12.1 and 12.2)

Material

63% Cu / 37% Zn

Dimensions & Shape

Conforms to IEC 60598-1:2014 figure 29,diameter: Ф2±0.2mm, the metal chain consists of links, uncoated

Resistance

2.5 Ω/m ±20% when stretched with a load of 200 g/m

Test Method