Products

IEC 60598-2-23 ELV Light Source Lifting Test Machine LCD Display

Products Description

IEC 60598-2-23 ELV Light Source Lifting Test Machine LCD Display

Applied Standards For Lifting Test Machine:

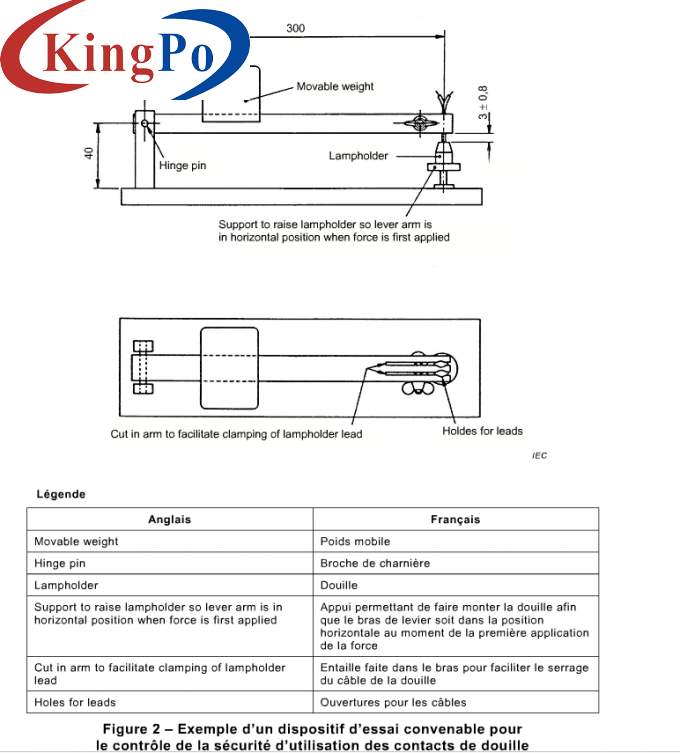

Conform to IEC 60598-2-17 clause 17.7.4. and IEC60598-2-23 Clause 7.4 and 7.5.

Technical parameters For Lifting Test Machine:

Basic Operation Before Use Lifting Test Machine:

1 Please set the test parameters before starting the test, otherwise the system will use the last parameters by default.

2 Please check and save the parameters after setting (it will be automatically saved in some interfaces), and the system will automatically use the saved parameters when the system is turned on next time;

3 Gain 1 is related to the sensitivity of the sensor, and can be matched with the hardware dial switch;

4 The position of the red dial switch has changed, and the hardware zero position should be re-calibrated.

Power is not entered

Check the rear power socket of the instrument.

Ask an electrician to check the repair power line

Check if the power station fuse is broken.

Button failure

Damaged relay

Motor speed box damaged

Tighten the screws securing the circuit board

Replace relay

Replace motor speed box

Capacity

0~1T

Accuracy level

Level 1

Control method

It is controlled by microcomputer

Display method

Electronic LCD display

Power unit

kgf, gf, N, kN, lbf

Stress unit

MPa, kPa, kgf/cm2, lbf/in2

Displacement unit

mm, cm, in

Display resolution

0. 1N

Lifting stroke

600mm

Platen size

600*600mm

Software function

Chinese and english are interchangeable

Shutdown mode

Overload shutdown, emergency stop button, automatic shutdown of test piece destruction, automatic shutdown of upper and lower limit settings

Safety equipment

Overload protection, limit element protection device

Machine power

AC variable frequency motor drive controller

Computer system

High precision ball screw

Power supply

Can be customized

Machine weight

Around 250KG

Performance characteristics

The percentage break value can be set, the machine will stop automatically, and 4 different speeds can be selected when enter the menu. 20 results are available, the average of all test results and single results can be viewed.

Fault situation

Possible Causes

Method of exclusion

Turn on the main switch of the instrument, the indicator light at the switch is not on.

Press the F3 key and F4 key no action