Products

IEC 60598-1 Leakage Tracking Test Equipment Tracking Index Testing CT1 PT1

Products Description

IEC 60598-1 Leakage Tracking Test Equipment tracking index testing CT1 PT1

Product information:

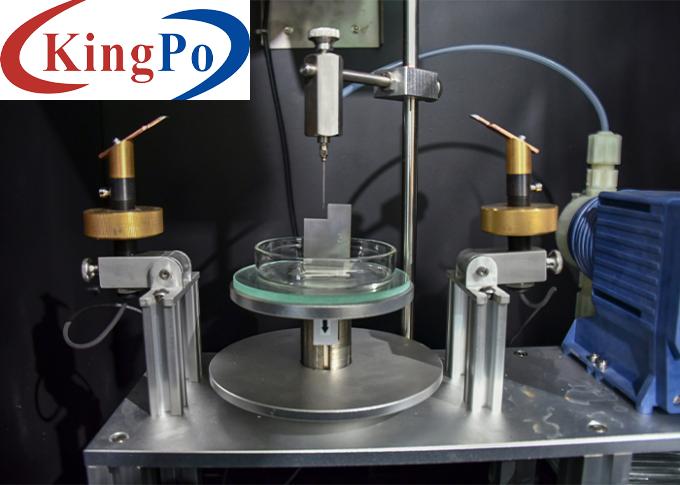

The tester is designed and manufactured according to the standard requirements of IEC60112, it is required by IEC60335-1 clause 29.2 and Annex N, IEC 60065:2014 clause 13.4, IEC60598-1, IEC 60884-1, UL746A and ASTM D3638-92 and etc. The working principle of the leakage tracking test (tracking index testing) is that the conducting liquid (0.1%NH 4 CL) of required volume in the required height (35mm) and required time (30s) drops with the voltage between the platinum electrodes (2mm × 5mm ) on the surface of solid insulating material. Thus the users evaluate the tracking resistance performance of solid insulating material surface under the combined influence of electric field and humid or contaminate medium. In a word, this device is used to measure the compare tracking index (CT1) and electrical resistance index (PT1).

A gauge block is supplied with the instrument to ensure the electrodes have the proper distance between them. The table height is easily adjustable to ensure the proper angle of the electrodes and height of drops. The rest of the test is controlled from outside the test chamber with the door closed. The voltage, limiting current, drip rate and number of drips are all set on the control panel. An operator should observe the test to see if a flame ignites. The instrument sounds an alarm if there is a tracking failure of at least two seconds.

The leakage tracking tester adopts to PLC control system and 7” color touch screen, it is suitable for the research, production and quality department of lighting equipment, low-voltage apparatus, household appliance, machine tool electric appliance, electrical machine, electric tool, electronic instrument, electrotechnical instrument, information technology equipment. I t is also suitable for the industry of insulating material, engineering plastics, electrical connector and accessories.

Features:

Leakage tracking test equipment is used to identify and locate electrical or electronic insulation failures that can lead to electrical leakage or tracking. These devices are specifically designed to detect and diagnose insulation problems in electrical systems, components, and devices. Here's an overview of leakage tracking test equipment and its key features:

High Voltage Source: Leakage tracking test equipment typically incorporates a high voltage source that applies a controlled voltage to the test object. The voltage level can vary depending on the specific application and testing requirements. The high voltage is used to stress the insulation and simulate operating conditions.

Technical parameters:

Parameter model

SN774 (0.5m³)

Working voltage

220V/50Hz,1KVA

Control

Advanced PLC

Display

7-inch color touch screen

Testing voltage

0~600V adjustable, precision 1.5%

Timing device

9999X0.1S

Electrode

Platinum electrode and brass electrode each for a pair

Electrode dimension

(5±0.1)×(2±0.1)×(≥12),

30°slant

Electrode included angle and distance

60°±5°, distance is (4±0.1㎜)

Electrode pressure

1.00N±0.05N(digital display is optional)

The interval of dropping liquid

30±5S, adjustable

Dropping liquid height

35±5mm

Dropping liquid delay

0.2S(solenoid valve opening time)

Dropping liquid size

45~50 drip/cm3

Time-delay circuit

2±0.1S(in 0.5A or larger current)

Short-circuit pressure drop

8% MAX

Short-circuit current

1±0.1A 1%

Wind speed

0.2m/s

Environmental requirement

0~40℃, relative humidity≤80%, in the place of no obvious vibration and corrosive gas

Equipment size & weight

1100mm* 550mm* 1100mm, 180KGS

Conforms to standard

IEC60112, IEC 60598-1, IEC60695, IEC 60884-1, UL746A, ASTMD3638, etc.

Leakage Current Measurement: These test devices are equipped with leakage current measurement capabilities. They monitor the flow of current through the insulation and detect any abnormal leakage or tracking current paths. Leakage current measurements help identify insulation deterioration, moisture or contamination ingress, or other insulation-related issues.

Voltage Breakdown Detection: Leakage tracking test equipment also includes voltage breakdown detection mechanisms. These mechanisms detect sudden voltage drops or breakdowns that occur when the insulation fails or breaks down under high voltage stress. Voltage breakdown detection helps identify weak points in the insulation and pinpoint areas requiring further investigation.

Test Object Connection: The test equipment provides different connection options to establish a secure and reliable connection with the test object. This can include probes, clips, or specialized connectors depending on the nature of the test object and the test setup.

Data Display and Analysis: Leakage tracking test equipment often features a display screen to show real-time measurements of leakage current, voltage, and other relevant parameters. Some devices may also offer data logging capabilities to record and analyze test results for further investigation or documentation.

Safety Features: Safety is a critical aspect of leakage tracking tests due to the high voltages involved. Therefore, these devices are designed with safety features such as built-in insulation and grounding to protect the operator from electrical hazards. They may also incorporate safety interlocks and indicators to ensure safe testing procedures.

Leakage tracking test equipment is commonly used in industries such as electrical manufacturing, power distribution, electronics, and telecommunications to assess insulation quality, identify potential failure points, and ensure the reliability and safety of electrical systems.