Products

IPX3 IPX4 Oscillating Tube Test Equipment Needle Pinhole Aperture Φ0.4mm

Products Description

IPX3 IPX4 Oscillating Tube Test System for Protection Against Spraying and Splashing Water

Overview:

This open type IPX3 and IPX4 oscillating tubes test system is used to verify the protective performance of the enclosure for electronic and electrical products, automobiles, motorcycle parts, household appliances, seals and lamps under water spraying and splashing at degree IPX3 and IPX4.

Standards compliant:

Structure:

The test equipment consists of an oscillating mechanism, an electrical control cabinet and a turntable. One end of the oscillating mechanism is mounted on the wall, and the other end of the oscillating mechanism is fixed on the floor support, the tube is caused to oscillate by motor driving. The turntable has a rotation speed of 1r/min, to make the enclosure of the specimen to be splashed in all directions. The test equipment is equipped with a water filter cleaning device to prevent pinhole blockage. This whole system adopts open structure.

Technical parameters:

R200, R400, R600, R800, R1000, R1200, R1400, R1600mm are optional, made of stainless steel

IPX3:over an arc of 60° either side of the center point (120°)

IPX4:over the whole 180° of the semicircle

Hole spacing: 50mm

IPX3:4s /cycle(2×120°);

IPX4:12s /cycle(2×350°);

How to change the different oscillating tubes?

The connection parts of the oscillating tubes adopt flange structure, which is easy for disassembly and installation, and the support structure can be movable to achieve different distances, that makes the overall system can be compatible with different sizes oscillating tubes.

Flange joint

Control & Operation

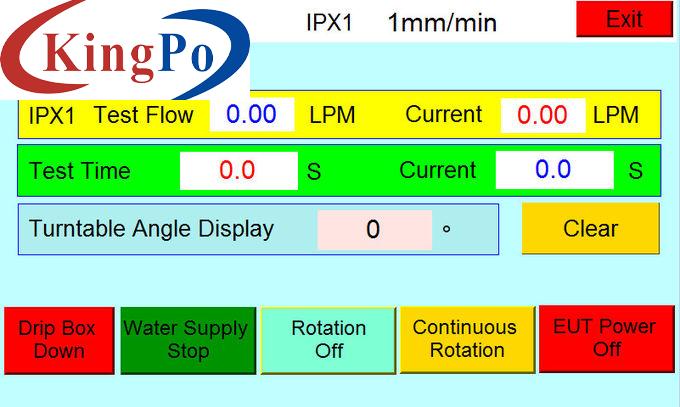

PLC and touch screen intelligent control system

Oscillating Tube Radius

Needle Pinhole Aperture

Φ0.4mm

Spray Holes Distribution

IPX3/4 Switching

Switching by changing a certain number of blind hole needles or through-hole needles

Oscillating Angle

IPX3:120°(±60°); IPX4:350°(±175°)

Oscillating Speed

Water Flow

1-10L/min adjustable

Test Time

0.01S~99.9 min, can be preset

Turntable

Diameter:Φ600mm, rotation speed: 1r/min, can pause at 4 angles, lifting height: 350-1000mm, load capacity: ≤50kg

Pressure Gauge

0~0.25MPa

Water Storage System

The control box and the water storage tank are integrated, the water storage tank is equipped with a water level float valve to automatically control the water inlet, and has high and low water level alarm detection, to effectively prevent the pump from being damaged due to dry water.

Optional

The handheld spray nozzle as per IEC 60529m figure 5 is optional

Safety Protection

Phase sequence protection, leakage protection, water shortage protection, abnormal protection

Equipment Dimensions

According to the sizes of the oscillating tubes selected