Products

Needle Flame Tester Electronic Steel Testing For Fire Hazard Measurement IEC 62368-1

Products Description

Needle Flame Tester Electronic Steel Testing For Fire Hazard Measurement IEC 62368-1

Product information:

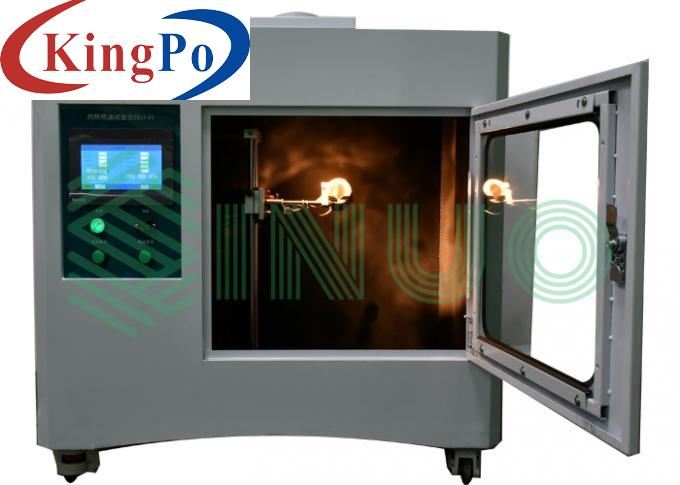

The Needle Flame Tester consists of a Ф0.9mm needle-shaped burner that tilts with the angel of 45°and provide it with butane gas. The fire hazard of the equipment when there is flammule inside the equipment that caused due to the fault condition is assessed by whether the specimen can be ignited or the combustion time and length. This tester conforms to the standard requirement of IEC60695-11-5, required by IEC 60598-1 clause 4.15.1, IEC60335-1 clause 30.2.3.2, Annex E, clause 13.3, etc.

The Needle Flame Tester has advanced PLC control and 7 inch color touch screen, it is suitable for the research, production and quality testing department of lighting equipment, low-voltage apparatus, household appliance, machine tool electric appliance, electrical machine, electric tool, electronic instrument, electrotechnical instrument, electrical connector, electrical and electronical equipment and other components. It is also suitable for insulating material, engineering plastics or other solid combustion material industry.

Features:

A Needle Flame Test Apparatus is a specialized piece of equipment used to assess the flammability of materials by subjecting them to a small, controlled flame. This test helps evaluate the ability of materials to resist the ignition of small flames, such as those caused by electrical faults or overheating components. Here is an overview of the Needle Flame Test Apparatus and its key components:

Needle Flame Test Apparatus Overview:

Technical parameters:

Needle Burner: The central component of the apparatus is the needle burner. It consists of a pointed metal needle connected to a gas supply. The needle is used to apply a controlled flame to the test sample during the test.

Gas Supply: The apparatus is connected to a gas supply, typically propane or butane, which fuels the flame produced by the needle burner. The gas flow rate is controlled to maintain a consistent flame during testing.

Control Panel: The control panel of the apparatus allows the operator to adjust parameters such as gas flow rate, flame height, and test duration. It also includes safety features and emergency stop controls.

Sample Holder: A sample holder or test chamber is used to secure the test samples during the test. The sample holder may have adjustable settings to accommodate different sample sizes and shapes.

Ignition Source: The needle flame serves as the ignition source in the test apparatus. It is applied to the surface of the test sample for a specified duration to determine the material's resistance to ignition and flame spread.

Observation System: The apparatus may include an observation system, such as a camera or magnifying glass, to closely monitor the behavior of the test sample during the test. This allows operators to record and analyze the material's response to the flame exposure.

Compliance with Standards: The Needle Flame Test Apparatus is designed to comply with specific industry standards and regulations, such as IEC 60695-11-5 or UL 94, which outline the testing procedures, criteria for ignition, and flame spread characteristics.

Needle Flame Test Procedure:

Preparation: Secure the test sample in the sample holder and ensure proper ventilation in the testing area.

Ignition: Apply the needle flame to the surface of the test sample for a specified duration, typically ranging from a few seconds to a minute, depending on the testing standard.

Observation: Monitor the behavior of the test sample during and after flame application. Note characteristics such as ignition time, flame spread, dripping, and afterflame duration.

Evaluation: Assess the test results against the criteria outlined in the relevant standards to determine the material's flammability rating.

Parameter/ model

SN773

Working voltage

AC 220V/50Hz

Control

PLC

Display

7 inch color touch screen

Timing device

9999X0.1S

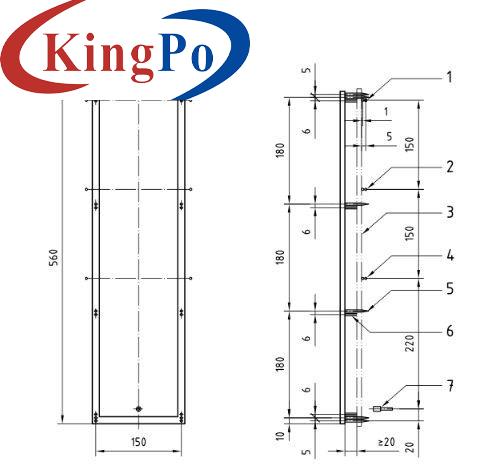

Combustor

Inner boreφ0.5mm ± 0.1mm , OD ≤φ0.9mm, L ≥ 35mm, stainless steel

Combustion angle

tilt 45°( testing ) or vertical ( when adjust the height of the flame)

Height of the flame

12±1mm adjustable(with flame height gauge)

Gas category

95% butagas ( can use the bottled lighter gas)

Range of temperature test

0~1000℃

Flame warming requirement

From 100°to 700°,time for standard values within 23.5S±1S

Temperature thermocouple

φ0.5 armour nickel-chromium/nickel aluminum wire K-Thermocouple

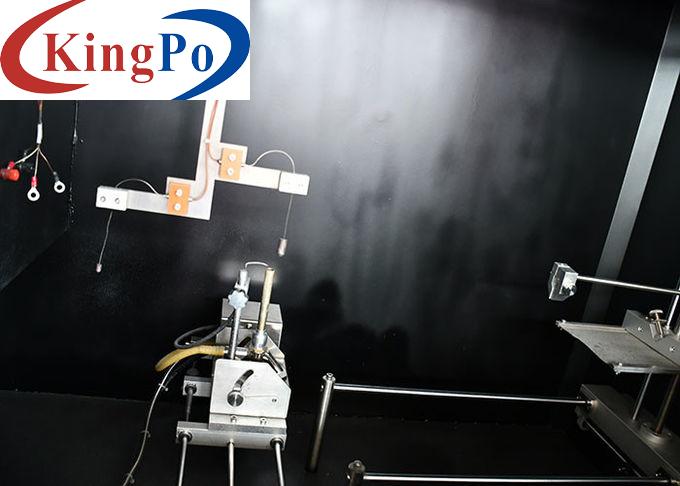

Work shop

0.5 cube, staunless steel case, black yogon background

Testing process

Test procedure automatic control, independent air draft

Volume size adjustment

Flowmeter adjustment

Equipment size & weight

1100mm* 550mm* 1100mm, 120KGS