Products

IEC 60695-2-2 Needle Flame Flammability Test Chamber Touch Screen

Products Description

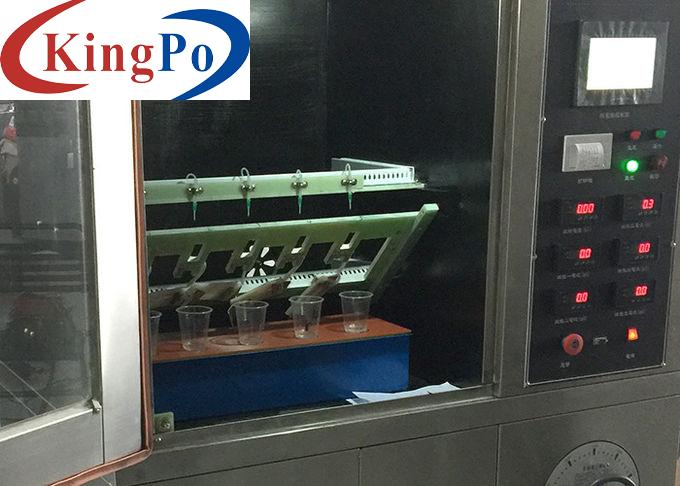

IEC 60695-2-2 Needle Flame Flammability Test Chamber PLC Control

Test principle:

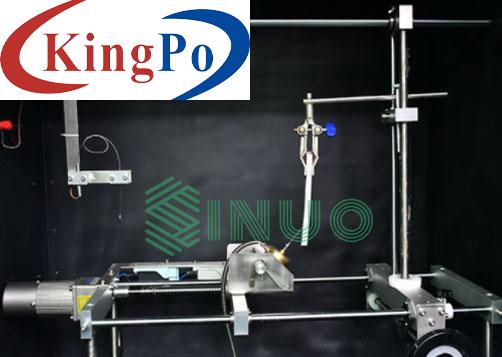

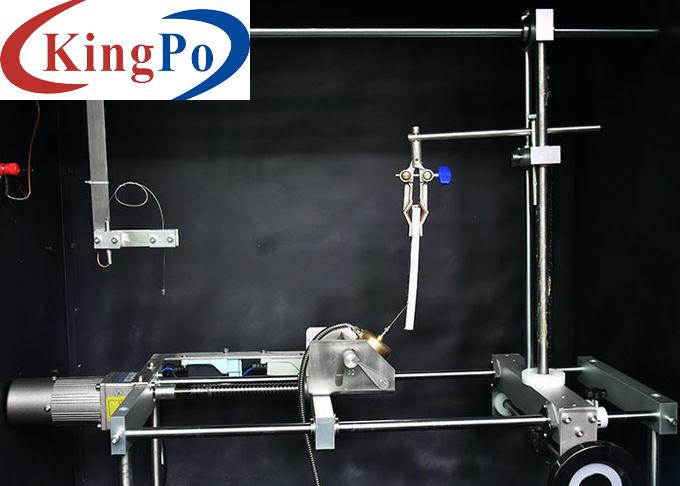

Needle flame tester is a needle burner with a specified size (φ 0.9mm), with specific gas (butane), with 45° Angle timing and directional burning test, depending on whether the test is ignited and holding the combustion time and combustion length to assess the fire risk of small flame caused by fault conditions inside the equipment.

Equipment advantages:

The device can give a quick and accurate warning: the time from 100°±5°C to 700°±3°C is 23.5s ±1s. When combustible occurs within the equipment due to failure conditions, the fire hazard of the equipment is assessed by the time and length of time the sample can be ignited or burned.

Technical parameters:

Needle flame test box is equipped with advanced PLC control, 7 "color touch screen, easy to operate.

Mainly used in lighting equipment, low-voltage electrical appliances, household electrical appliances, machine tools, and other components of the research, production and quality testing departments. Also suitable for insulating materials, engineering plastics or motor, power tools, electronic instruments, electrical instruments, electrical connectors, electrical and electronic equipment and other solid burning materials industry.

Parameter/ model

SN773B (PLC + touch screen version)

Working voltage

Match client's local power supply requirements

Control

Advanced PLC

Display

7 inch color touch screen

Timing device

9999X0.1S

Combustor

Inner boreφ0.5mm ± 0.1mm, OD ≤φ0.9mm, L ≥ 35mm, stainless steel

Combustion angle

tilt 45° (testing) or vertical (when adjust the height of the flame)

Height of the flame

12±1mm adjustable (with flame height gauge)

Gas category

95% Butane (should be prepared by user)

Range of temperature test

0~1000℃

Flame warming requirement

From 100°to 700°, time for standard values within 23.5S±1S

Temperature thermocouple

φ0.5 armour nickel-chromium/nickel aluminum wire K-Thermocouple

Work shop

0.5 cube, stainless steel case, dark background

Testing process

Test procedure automatic control, independent air draft

Volume size adjustment

Flowmeter adjustment

Equipment size & weight

1100mm* 550mm* 1100mm, 120KGS

Conforms to standard

IEC 60695-11-5, IEC60335-1, etc.