Products

Needle - Flame Testing Method Flammability Test Chamber Small Flame Effect Fire Hazad Test IEC 60695-11-5

Products Description

IEC 60695-11-5 Needle-flame Testing Method Small Flame Simulation Fire Hazad Test Appratus

Overview:

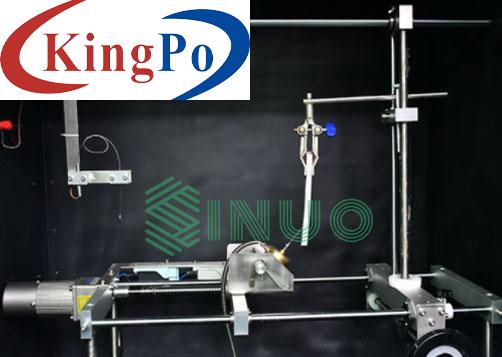

This needle flame test is used to simulate the effect of small flames that may arise in malfunctioning electrical equipment.

The burner which produces the 12 mm high test flame shall consist of a tube at least 35 mm long with a bore of 0.5mm±0.1mm and outer diameter not exceeding 0.9mm. The burner is supplied with butane or propane gas having a purity of at least 95%. There shall be no air admitted to the burner tube. To evaluate the possibility of spread of fire, for example by burning or glowing particles falling from the test specimen, a layer of the material or components normally surrounding or situated underneath the test specimen and the surrounding material or components when the test specimen is mounted as in normal use.

The test flame is positioned so that the tip of the flame is in contact with the surface of the test specimen. The test flame is removed after the specified time.

If the test specimen drips molten or having flaming material during the application of the flame, the burner may be tilted up to 45°from the vertical to prevent material from dripping into the burner tube while maintaining an 8mm±1mm spacing between the centre of the top of the burner and the remaining portion of the test specimen, ignoring any strings or molten material.

Standards:

IEC60695-11-5

IEC 60695-2-2

Technical Parameters:

Application:

This needle-flame tester is applicable to testing electrical equipment, its sub-assemblies and components, as well as solid electrical insulation materials or other combustible materials, such as lighting, low-voltage electrical appliances, household appliances, machine tool electric appliance, electric motor, electric tools, electronic instruments, electrical instruments, electrical connector, rubber, plastic materials and etc.

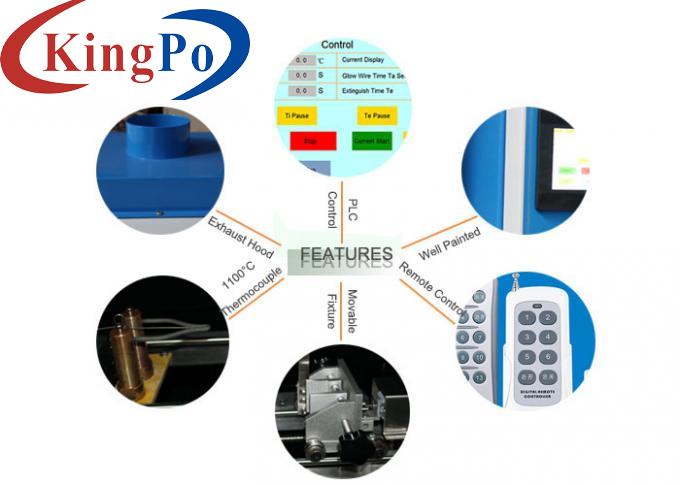

Control mode

Button operation + romote controller

Display mode

Precious digital meters

Chamber Structure

Stainless steel plate with high-grade paint

Button switch

Top grade button

Combustion gas

Butane or propane gas, purity ≥ 95%

Flame application time

0-9999.9s can be preset

Flame duration

0-9999.9s display, automatic recording

Time resolution

0.1s

Flame temperature rising time

From 100℃ ± 2℃ to 700℃ ± 3℃ ( room temperature~ 999℃ ) ,23.5s±1.0s (1s ~ 999.9s)

Flame height

12mm ± 1mm ( ajustable )

Combustion angle

0°, 20°, 45° (adjustable )

Needle burner

Stainless steel,bore diameter:Φ 0.5mm ± 0.1mm,outer diameter ≤Φ 0.9mm ,length≥35mm

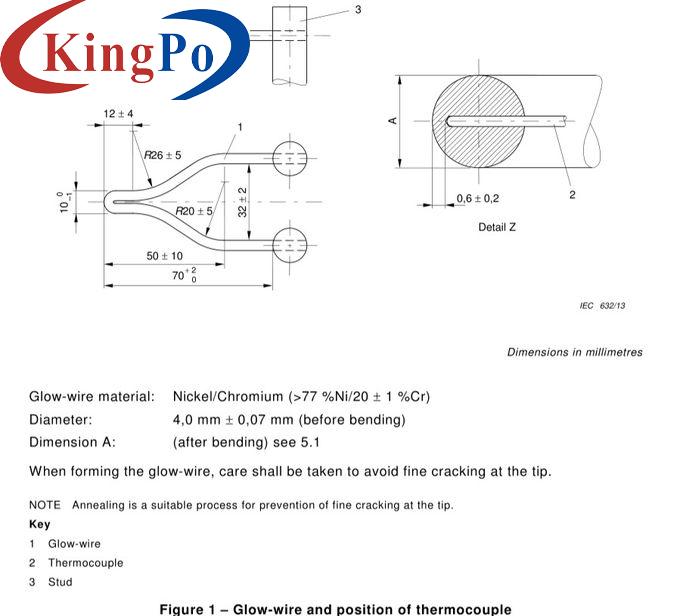

Copper block

The copper block material is specified as : Cu-ETP UNS C11000 (see ASTM-B187). The diameter of the copper block shall be 4mm 0.01mm with a mass of 0.58g 0.01g in the fullu machined and polished but undrilled state.

Thermocouple

Imported Omega brand Φ 0.5 armour nickel-chromium / nickel aluminum wire K type thermocouple, temperature resistance 1100°C

Temperature sensing delay

1.7S

Test space

≥ 0.5m³, black yogon background

Dimensions

L1100mm × W530mm × H1150mm ,Exhaust aperture:Φ100mm;

Power supply

220V /50Hz, 0.5kVA (110V, 60Hz or other power supply can be customized)

Standard

IEC60695-11-5, IEC 60695-2-2