Products

Accessories For Flammability Test Chamber Gauges Electrodes Burners

Products Description

Accessories for Flammability Test Chamber Gauge Thermocouple Burner

Product overview:

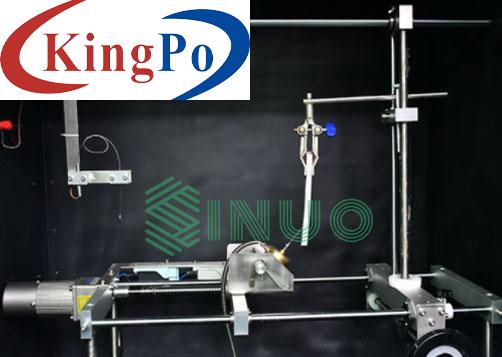

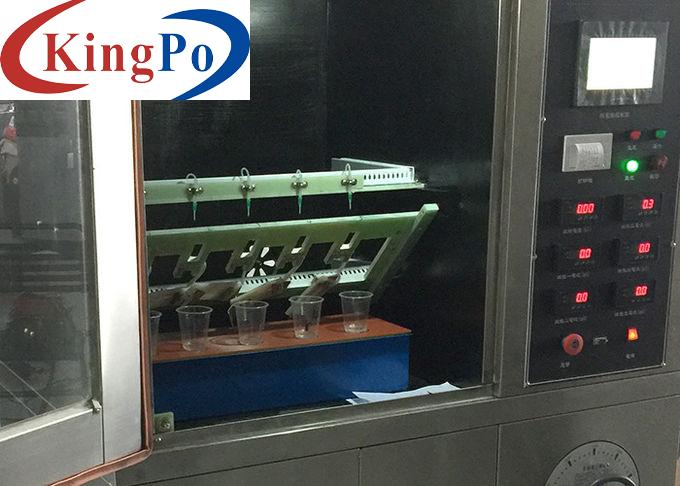

These accessories are for various of flammability test chambers, such as glow wire test apparatus, needle-flame test apparatus, tracking leakage test apparatus, horizontal and vertical burning test apparatus.

Technical Parameters:

KingPo have various of spare parts for flammability test chambers, these spare parts are strictly made according to the requirements of different standards, can pass third party calibration.

The glow-wire in the glow-wire test apparatus

Name & Model No.:

Flammability Accessories

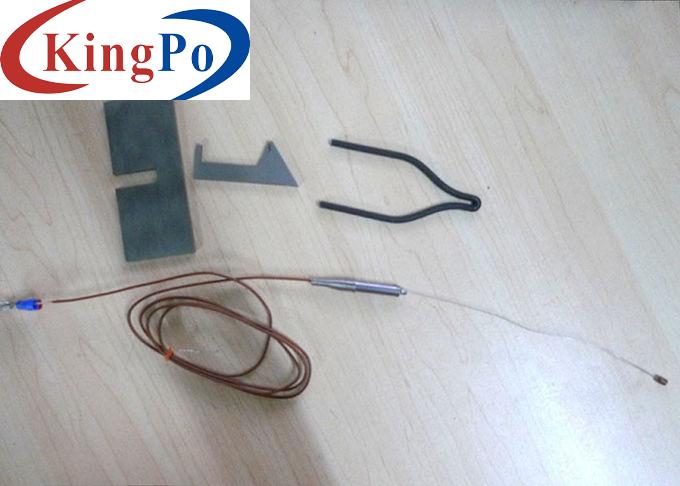

Glow wire U head

Ф4mm ± 0.04mm (> 77 % Ni/20 ± 1 % Cr) standard shape

Ф1mm thermocouple

Ф1 Armored nickel-chromium/nickel-aluminum wire, K type, temperature resistance 1100°

Ф0.5mm thermocouple

American original Omega Ф0.5 armored nickel-chromium/nickel aluminum wire, K type, temperature resistance 1100°

Silk paper

180×180mm,12-30g/m2

Pine board

180×180×10mm

Temperature measuring copper head

50W:Ф5.5±0.01mm;500W: Ф9.0±0.01mm; needle-flame: Ф4.0±0.01mm

Platinum electrode

(5.0±0.1)×(2.0±0.1)mm, 30°±2° bevel, blade width 0.01-0.1mm, platinum purity greater than 99.0%