Products

IEC 60112 Proof and Comparative Tracking Indices Testing Equipment PLC Control Tracking Test Chamber

Products Description

Solid Insulating Materials Proof and Comparative Tracking Indices Testing Equipment PLC Control Tracking Test Chamber

Overview:

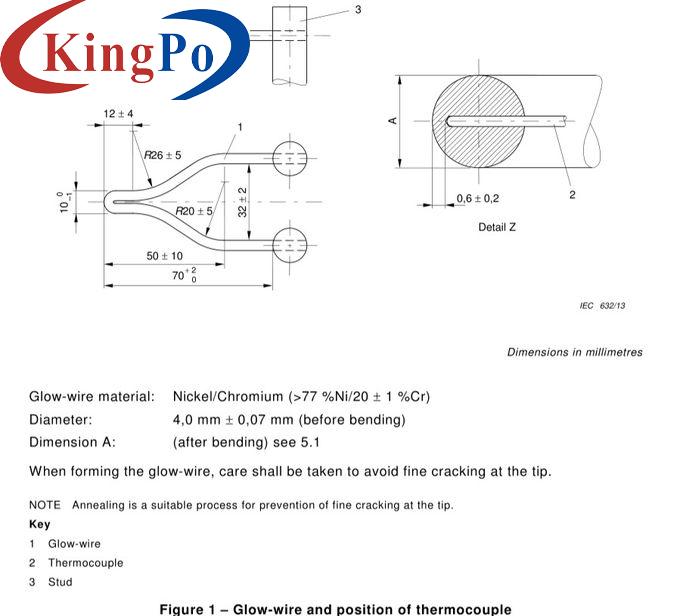

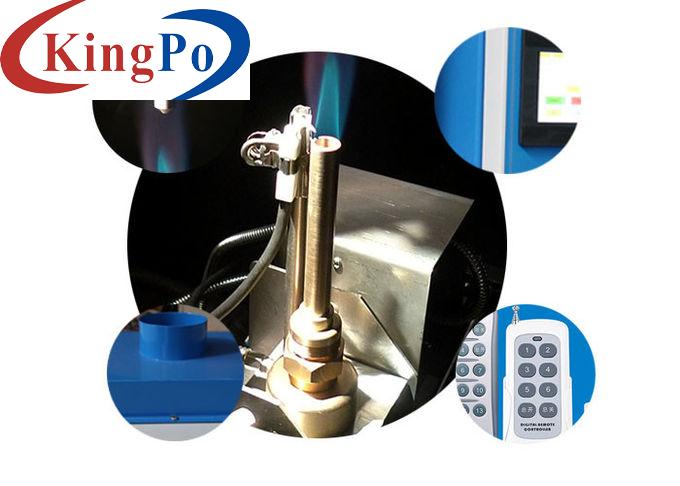

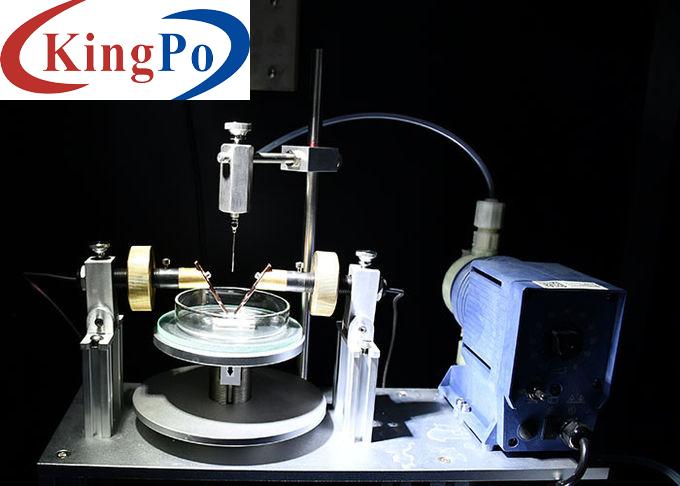

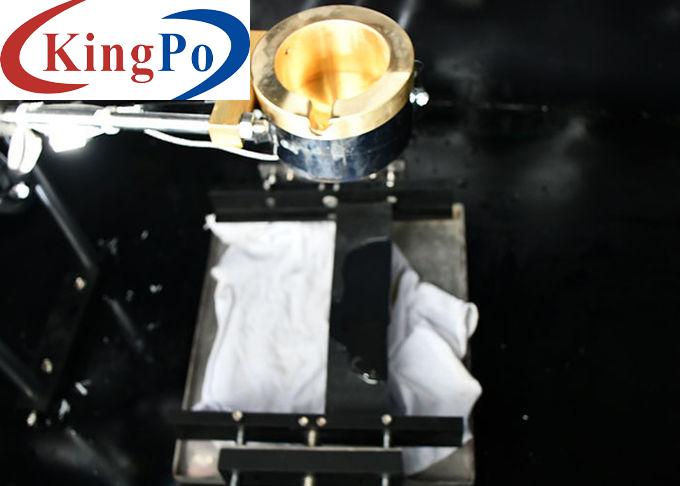

This tracking leakage testing equipment is designed according to IEC 60112. It is used for the determination of the proof and comparative tracking indices of solid insulating materials on pieces taken from parts of equipment and on plaques of material using alternating voltages.

If electrical products affected by moisture and impurities environmental, leakage may be caused on the insulation between different polarity live parts or live parts and grounded metal, the generated arc will cause short circuit or electrical erosion due to discharge, even cause fire. The tracking test is a destructive test to insulating material simulating the above situation, to measure and assess the relative resistance to tracking when the insulator is in the effect of electric and impurities in water-containing.

Technical Parameters:

Mitsubishi PLC

With additional infrared remote controller

7 inch Weinview color touch screen

0~600V,accuracy:1.5%

This equipment adopts advanced PLC control system, touch-screen humanized button operating device, high quality materials and professional technology, which make itself has excellent quality, stable and durable performance and beautiful appearance. In addition, automatic drip timing device, accurate electrode pressure sensor display, simple operation and high accuracy improve the efficiency of the test and make our equipment takes a leading position in similar products.

Control Mode

Display

Electrode material

Platinum

Electrode specifications

5mm*2mm

Electrode spacing

4±0.1mm

Electrode pressure

1±0.05 N

Electrode angle

60°

Short circuit voltage drop

1±0.1A , Accuracy: 1%

Drip interval time

Adjustable

The height of the drip

30~40mm

Drip delay time

0.2S (solenoid valve open time)

Delay electric circuit

2 ± 0.1S (at 0.5A)

Test voltage range

Working volume

> 0.5 M³

Power supply

220V,50Hz or 110V, 60Hz (can be customized)

Environmental requirements

0 ~ 40 ℃ / ≤ 80% relative humidity

Standards

IEC60112, UL746A, IEC60695, ASTMD3638.