Products

ISO11925-2 PLC Control Building Material Flammability Test Device

Products Description

ISO11925-2 PLC Control Building Material Flammability Test Device

Product information:

The flammability test device for building materials is designed and manufactured according to GB/T8626-2007and the ISO11925-2:2020 standard. In a normal combustion environment, a small flame is used to directly impact a vertically placed sample to determine the flammability of building products.

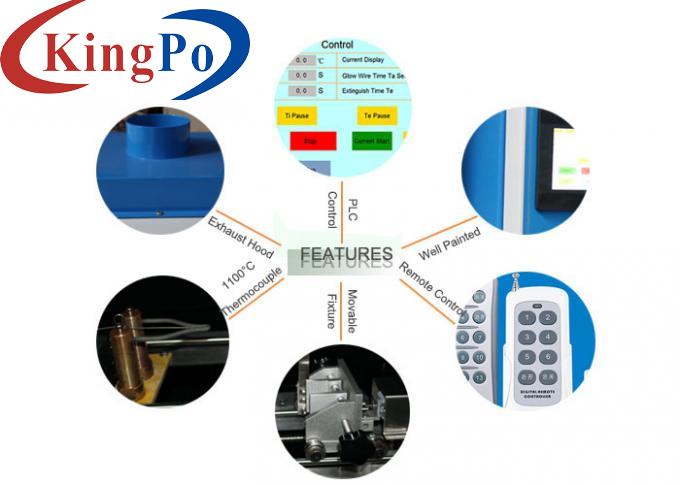

The device adopts PLC control, touch screen operation, stainless steel box, built-in blowtorch and adjustment mechanism, sample holder and adjustment mechanism, and the size requirements are strictly produced according to the standard. It is a dedicated building material combustion grade testing machine.

Parameters:

1. Input power supply:AC220V 50Hz, environment temperature: 15℃~35℃, relative humidity: ≤85%

2. PLC control, 7-inch color touch screen operation;

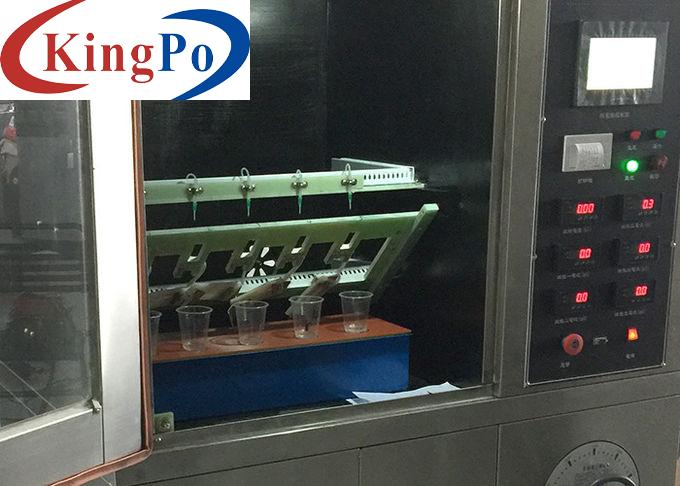

3. Combustion box: It is made of 1.5mm stainless steel plate according to the standard picture 1. The front and right sides are opened and tempered glass is installed. The overall dimensions are 1000mm wide × 400mm deep × 810mm high, including the size of the electric cabinet, and the bottom of the box is flat Natural vents, the vents are composed of 5cm*5cm square vents (real 1.5mm thick steel plate vents, 50mm high) to keep the air flowing smoothly;

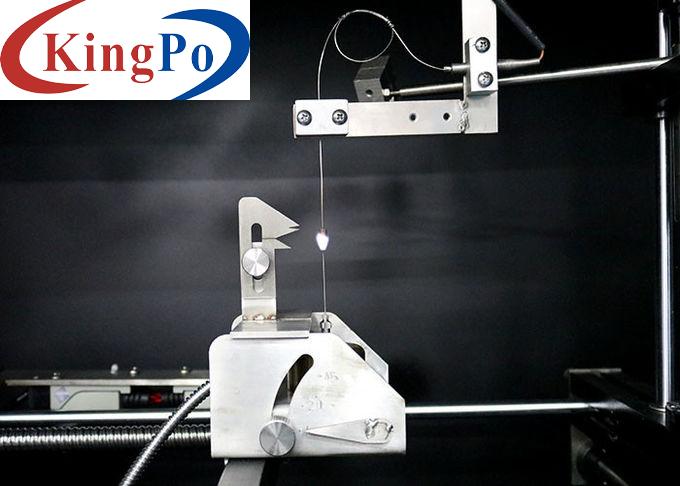

4. The Bunsen burner is made according to the standard picture 2, and its mounting bracket can be adjusted back and forth, and can be adjusted vertically and 45°;

5. Gas: commercial propane with a purity of ≥95%, the gas pressure is within 10~50kPa, and the user should prepare it by himself.

6. Sample mounting bracket: made according to standard picture 3, installed vertically according to picture 4, adjustable

7. Flame height gauge, made according to the standard picture 8, 20mm away from the mouth of the torch

8. Burner positioner: made according to the standard picture 9, 1 edge ignition, 1 surface ignition

9. High pressure automatic ignition, durable combustion;

10. Test flame: the flame height is adjusted by the flow meter, the height is 20±1mm, and it is measured with the flame height gauge;

13. Flame setting time: 0-999.9s, can be preset

14. Test time: 0-999.9s (including ignition time), can be preset

15. Anemometer: Accuracy ±0.1m/s, used to test the air velocity at the top outlet of the combustion box.

Standards compliant:

ISO11925-2:2020(E)

GB/T8626-2007

ambient temperature

15℃~35℃

combustion box

1.5mm stainless steel plate

Shape size

1000*400*810

Gas pressure

10~15kPa

Test Flame Height

20±1mm

Test Time

0-999.9s

Flame setting time

0-999.9s, can be preset

Anemometer Accuracy

±0.1m/s