Products

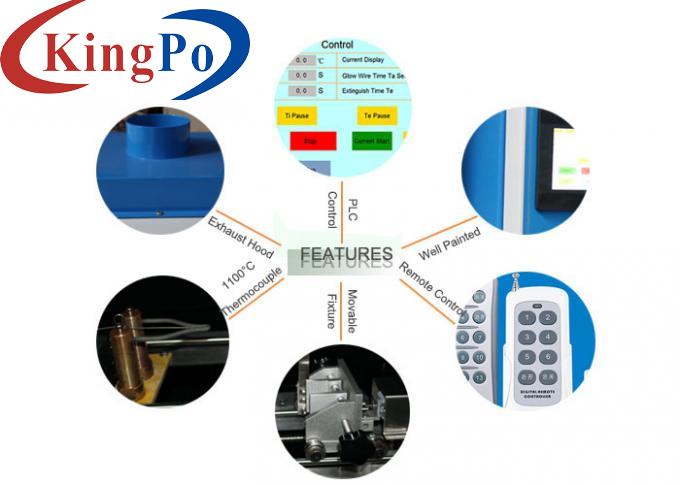

IEC 60335-2-10 Glow Wire Flammability Test Chamber Fire Risk Assessment Equipment Button Operation

Products Description

IEC 60335-2-10/11/12/13 Materials Glow-wire Ignitability test Equipment Fire Risk Assessment Apparatus

Overview:

This fire hazard test device simulates the thermal stress caused by the heat source or ignition source such as the glowing elements or overload power within the short period of time, applicable to the fire hazard test for the electric and electronic products, household appliances and the materials, and also used for the no-flame ignition source fire test in order to measure the ignition temperature, flammability and heat-resistance index of the glow wire made of the relevant materials.

Standards:

IEC60695-2-10

IEC60695-2-11

IEC60695-2-12

IEC60695-2-13

UL746A

Technical Parameters:

220V /50Hz or 110V/60Hz

(can be customized according client's requirements)

Calibration temperature:960°±10°C

The glow wire element is heated by electric heating

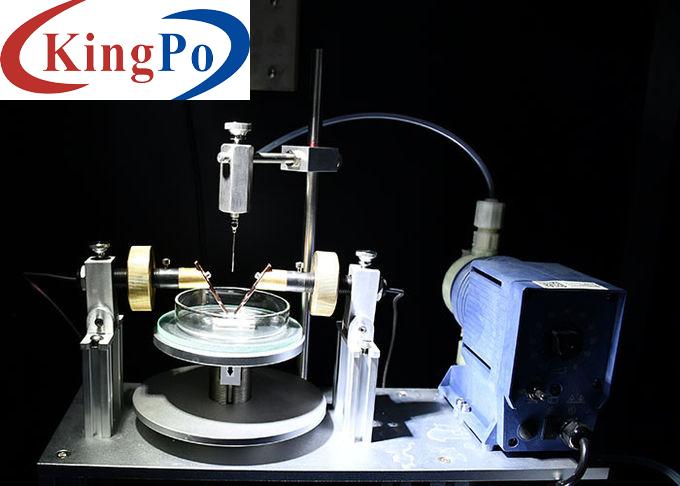

Thermocouple: imported original BB 1mm armour nickel-chromium/nickel/ nickel aluminum K-Thermocouple, temperature resistance up to 1100°C

Packing:

KingPo offers thoughtful solutions, high quality products, customer services, also we care about the delivery safety of all packing.

Model

SN772A

Working voltage

Control operation mode

Button control +with infrared remote controller

Display

Meters

Glow-wire element

Ф4mm ± 0.04mm (> 77 % Ni/20 ± 1 % Cr) special standard ring shape, horizontal standing

Specimen pressure on glow-wire element

0.95N±0.1N

Maximum depth of heating

7mm ± 0.5mm

Specimen movement speed

10mm /s ~ 25mm /s

Temperature calibration

Silver foil: purity 99.8%, area :2mm², thickness:0.06mm

Tray

A layer of silk paper (12~30g/m³) is covered on the 10mm thick pine board, with a distance of 200±5mm below the test sample

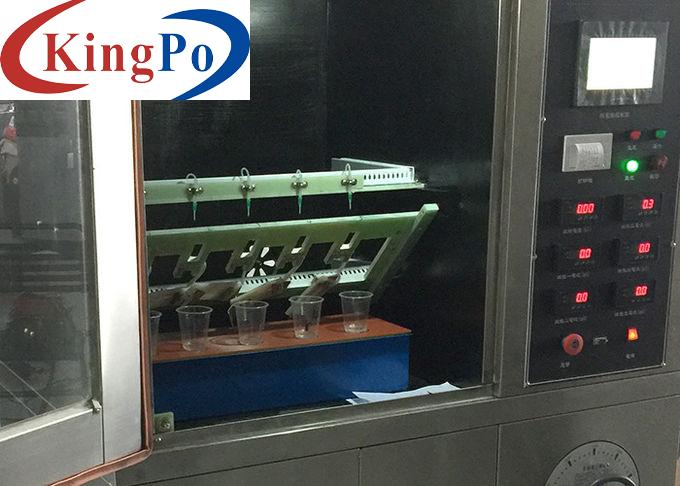

Test chamber

>0.5 cube, sample distance from the inside of the chamber is greater than 100mm, black yogon background,background illuminance ≤ 20Lx,with exhaust fan

Glow-wire time

30s±1s

Test procedure

The test sample is clamped on the movable fixture, the movable fixture can run forward automatically after testing started and will return automatically after glow-wire time is finished

Lighting

Equipped with lighting in the test chamber

Dimension

1100*550*1200mm, 140kg