Products

Clause 26.7.2 IEC 62196-1 3K/Min Temperature Change Test Chamber

Products Description

IEC 62196-1 Change of Temperature Test Rapid Temperature Change Chamber

Product information:

This rapid temperature change test chamber is required by IEC 62196-1 Ed.4CDV 2020 clause 26.7.2.

It is used for cold, heat, humidity and dryness testing of raw materials and devices such as electronics, electricians, electrical appliances, plastics, etc. The purpose is to confirm the reliability of storage, transportation and use of products under high and low temperature rapid alternating humid heat environment.

Manufactured in accordance with standards:

IEC60068-2-1:2007 “Environmental Testing-Part 2-1: Tests-Test A: Cold, IDT”

IEC60068-2-2:2007 “Environmental Testing-Part 2-1: Tests- Test B-Dry heat, IDT”

IEC60068-2-78:2012 “Environmental Testing-Part 2-78: Tests-Test Cab: Damp heat, steady state, IDT”

IEC60068-2-30:2005 “Environmental Testing-Part 2-30: Tests-Test Db: Damp heat, cyclic (12h+12h cycle), IDT”

Technical parameters:

1000L: inner size: WDH=1000×1000×1000mm,

outer size: WDH= 1200 ×2015×2035 mm (excluding protruding parts of the machine)

Heating rate: from -30℃ to +100℃, linear speed 3℃/min (non-load)

Cooling rate: from +100℃ to -30℃, linear speed 3℃/min (non-load)

(Note: The temperature heating and cooling rate is measured according to the relevant regulations of the IEC60068-3 standard, and the sensor is at the air outlet position)

20%〜98%RH

Function: fixed value test and program test

Fixed value test: When the test environment requires only a single temperature and humidity, selecting this mode to set the required temperature, humidity and running time.

Program test: When the test environment requires multiple temperatures and humidity, select this mode to set the temperature, humidity and running time of each program. User can set the program running sequence. The program group is up to 100 groups.

Control & Operation

PLC and touch screen intelligent control system

Chamber Size

Temperature Range

B: -40~150℃;

Linear Speed

3℃/min

Temperature Deviation

≦±2.0℃

Temperature Fluctuation

±0.5℃

Temperature Uniformity

±2℃

Heating and Cooling Rate

Humidity Range

Humidity Deviation

±3.0%RH (>75%RH); ±5.0%RH (≤75%RH)

Humidity Uniformity

±3.0%RH (non-load)

Humidity Fluctuation

±2.0%RH

Temperature and Humidity Range Icon

System Main Composition

Chamber Body

The inner chamber is made of high-quality carbon steel plate, the surface is treated with electrostatic color spraying

The inner chamber is made of 304# brushed stainless steel plate, rounded shape, smooth, easy for clean

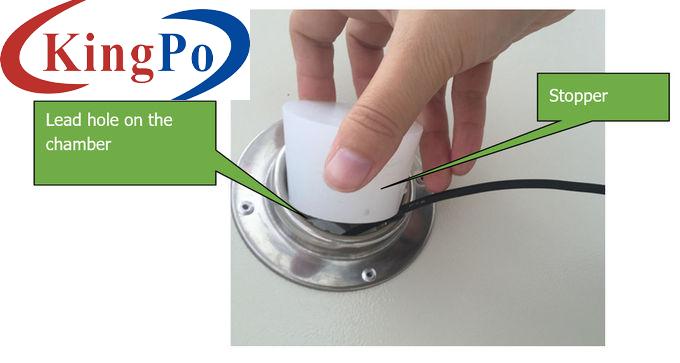

Lead hole: the inner and outer chamber are equipped with a threading hole with a rubber stopper

Insulation material: polyurethane foam

Observation window: double-layer explosion-proof tempered glass door

Shelves: Made of 304 stainless steel, detachable shelves

Heating System

Heating method: electric heating

High quality nickel-chromium wire electric heater, contactless control (SSR)

Humidification System

Humidification method: external humidification structure

Cooling System

German Bock semi-tight compressor or German BITZER semi-compact compressor

Non-fluorine environmentally friendly refrigerant R404A R23, in line with environmental regulations, safe and non-toxic

Shell and tube condenser (water cooled)

High-performance fin type automatic load capacity adjustment, long-term use of low temperature and high humidity conditions without frosting.

Control System

Touch screen: programmable temperature and humidity controller (7 inch 16-bit true color touch screen)

Temperature control: PID self-tuning, using Class A PT100 platinum resistance sensor

Data Storage

With temperature and humidity curve interface, with standard R232 interface or U disk communication interface, the data can be downloaded, and the data changes and processes can be recorded.

Safety Protection

Power-off memory function, phase sequence protection, leakage protection, over-temperature protection, compressor overload protection, water shortage alarm, abnormal protection

Safety Protection Device

Heater air-burning protection switch, heater over current circuit breaker, circulating fan over current overload protection

Compressor high voltage protection switch, compressor overheat protection switch, compressor over current protection switch

Under-reverse phase circuit breaker, no-fuse switch, zero-crossing gate fluid power controller

Alarm Indication

When the above protection occurs, the equipment stops running, an audible and visual alarm is issued, and the fault location is displayed on the meter.