Products

Clause 26.2 0.535kg Steel Ball Impact Test Apparatus For Vehicle Plugs Connectors

Products Description

IEC 62196-1 Vehicle Plugs Socket-outlet Connectors Accessories Ball Impact Test Apparatus

Product information:

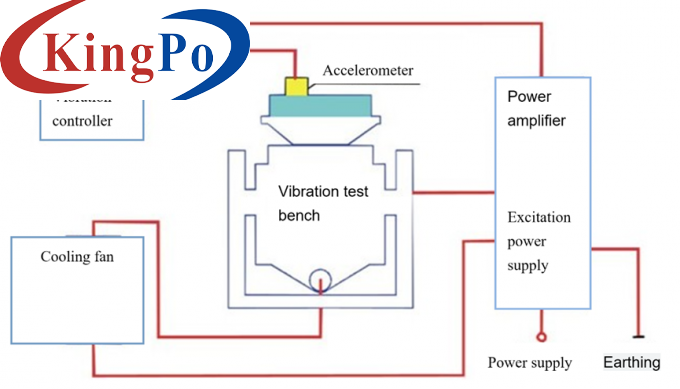

This ball impact test apparatus is requried by IEC 62196-1Ed.4CDV 2020 clause 26.2, fig18, table 13. It is suitable for drop impact test for equipment enclosure.

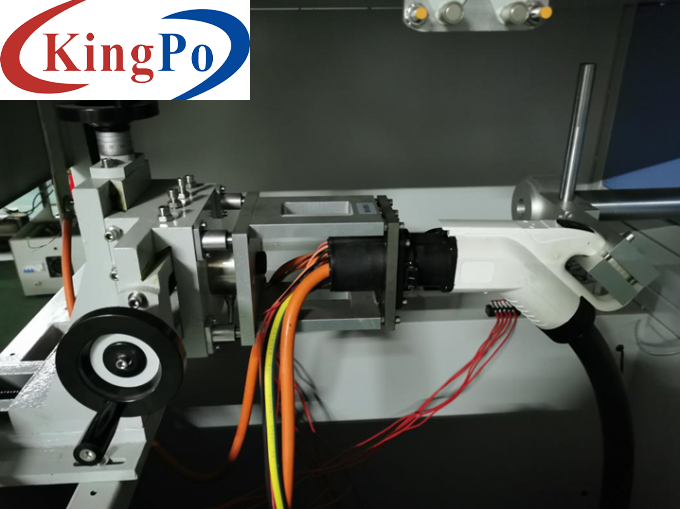

Test sample: Vehicle plugs socket-outlet connectors accessories, Luminaries, Audio, video and similar electronic apparatus, Information technology equipment

Feature: Equipment can carry out test in two forms of vertical drop and swing impact.

Technical parameters:

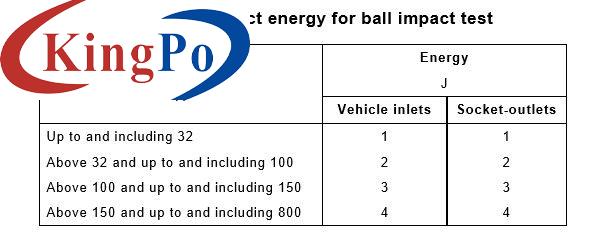

Impact energy according to the following table:

No.:

Item

Specification

1

Impact steel ball

Diameter 50.8mm, 0.535kg

2

Drop height

0.4-1.5m adjustable

3

Lift mode

Electric

4

Clamping release mode

5

Power supply

Match client’s local power supply requirements

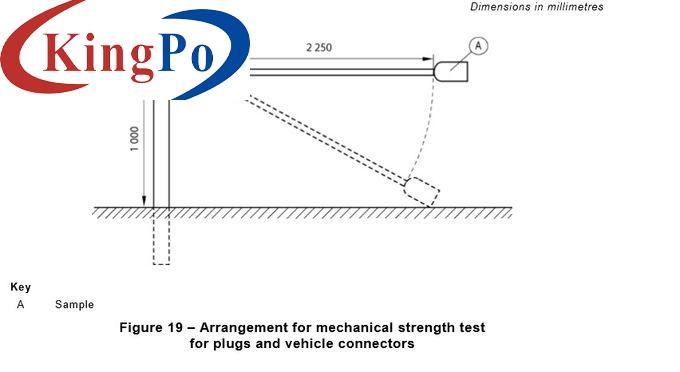

The first four blows are applied when the accessory is mounted as in normal use on a vertical board. The ball pendulum shall be mounted so that it swings parallel to that board. The impact face of the ball pendulum shall be arranged such that when the ball pendulum hangs freely, the impact face just touches the side of the accessory. The point of contact 1940

shall be substantially at the geometric centre of the side face of the accessory, or the appropriate projections of that face. The ball pendulum is then raised, released and the blow applied. The accessory is then revolved 90° about an axis perpendicular to the mounting face and its relationship to the impact face corrected, if necessary. A second blow is then applied.

The same procedure is repeated for two successive rotations of 90°, with a total of 4 blows being applied.

The fifth blow is applied with the plane of the ball pendulum perpendicular to the plane of the mounting board such that the ball pendulum strikes the sample at its furthermost projection from the mounting board.