Products

IEC 61851-1 Clause 12.9 High Low Temperature Climate Chamber

Products Description

IEC 61851-1 Clause 12.9 High & Low Temperature Climate Chamber

Applied standards:

IEC 61851-1 clause 12.9 and 12.10, IEC 61851-23 clause 101.2.1.1

IEC60068-2-1:2007 “Environmental Testing-Part 2-1: Tests-Test A: Cold, IDT”

IEC60068-2-2:2007 “Environmental Testing-Part 2-1: Tests- Test B-Dry heat, IDT”

IEC60068-2-78:2012 “Environmental Testing-Part 2-78: Tests-Test Cab: Damp heat, steady state, IDT”

IEC60068-2-30:2005 “Environmental Testing-Part 2-30: Tests-Test Db: Damp heat, cyclic (12h+12h cycle) , IDT”

Power supply: AC380V±5%/50Hz (R, S, T, N phase plus ground wire) (voltage fluctuation ≦ ±10%), grounding resistance ≦ 4Ω

Ambient temperature: 5 °C ~ +35 °C, relative humidity: ≦85% RH should not have high concentration of dust, corrosive gas, flammable and explosive objects

8m3: WDH=2×2×2m

12m3: WDH=3×2×2m

20m3: WDH=2×2×5m

50m3: WDH=5×2×5m

Maximum test temperature: 80 ° C, 120 ° C;

Minimum test temperature: -60 ° C, -40 ° C, -20 ° C, 0 ° C

Features:

This programmable temperature chamber is required by:

Samples and Restrictions

Electrical, electronic, mechanical and large parts, semi-finished products, finished products, etc.

Application

It is used for high and low temperature and damp heat tests on electricians, electronics, machinery, and large parts, semi-finished products, and finished products. Process quality and reliability testing of products, parts, etc. under simulated temperature and humidity conditions.

Test Principle

The heating, humidification and refrigeration system is used to control and change the ambient temperature and humidity in the chamber, simulating the ambient temperature / humidity and alternating procedures required by the testing.

Structure

Adopts closed chamber structure

Use Environment

Control & Operation

PLC and touch screen intelligent control system

Chamber Size (Optional)

Temperature Range (Optional)

Temperature Deviation

≦±2.0℃

Temperature Fluctuation

±0.5℃

Temperature Uniformity

±2℃

Humidity Range

30%〜98%RH

Humidity Deviation

±5.0%RH

Heating Rate

≤2.5°C/min (nonlinear, no load)

Cooling Rate

Average 1.0 ° C / min

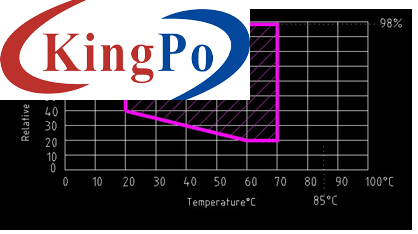

Temperature and Humidity Range Icon

1. The test system has advanced and reasonable structural design, standardized manufacturing process, beautiful appearance and generous appearance.

2. The main functional components of the test chamber are world famous branded ones. The test chamber has best control of noise and energy saving.

3. The matching of components and assembly is good. The main functional components are imported from the internationally branded companies, which improves the safety and reliability of the test chamber, and can ensure the long-term, high-frequency usage purposes.

4. The equipment has good operability, maintainability, good temperature stability and durability, good safety performance. It does not pollute the environment and endanger human health.