Products

EN 61010-031 Probe Wire Flexing Test Equipment Flexing Test And Rotation Test

Products Description

EN 61010-031 Probe Wire Flexing Test Equipment Flexing Test And Rotation Test

Product Information:

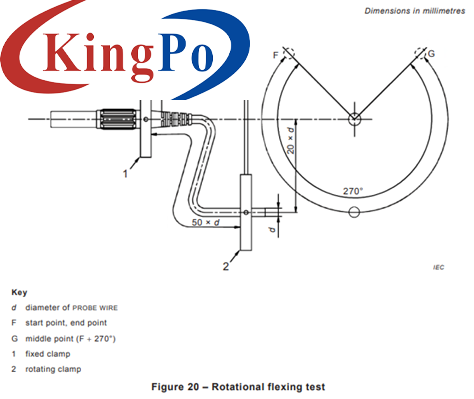

Standard: EN 61010-031:2015 Clause 6.7.4.3 flexing test Clause 6.7.4.4 Rotational flexing test.

Application: It is used to check that the probe wire is adequately protected against excessive flexing where it enters the appliance.

Feature: The test cycles, flexing angles, speed, voltage, etc., can be preset.

Features:

EN 61010-031 is a safety standard that specifically addresses the requirements for electrical equipment used in laboratories. It includes guidelines for probe wire flexing tests, which evaluate the durability and mechanical integrity of probe wires used in electrical testing and measurement devices.

To conduct the probe wire flexing test according to EN 61010-031, specialized testing equipment is required. While the specific design and features of the equipment may vary, below are some components and features commonly found in such equipment:

Test Fixture: The equipment includes a test fixture or holder designed to securely hold the probe wire during the flexing test. It ensures proper alignment and controlled movement of the wire during the test.

Technical Parameters:

Fixed on the machine shown as following:

Flexing Mechanism: The equipment incorporates a mechanism to induce controlled flexing or bending of the probe wire. This mechanism may consist of motorized rollers, pulleys, or other devices that apply repetitive flexing motions to the wire under specific test conditions.

Speed and Stroke Control: The equipment allows for adjustable speed and stroke control, enabling the simulation of different flexing conditions specified in the standard. This feature ensures consistency and repeatability in the testing process.

Counter or Timer: A counter or timer is included in the equipment to accurately record the number of flexing cycles performed during the test. This information is essential for evaluating the wire's durability and assessing its compliance with the standard's requirements.

Wire Tension Control: The equipment may incorporate a mechanism to control the tension applied to the probe wire during flexing. Proper tension control ensures that the wire is subjected to the intended flexing conditions without excessive strain or deformation.

Safety Features: Safety considerations are crucial in the design of probe wire flexing test equipment. The equipment may include safety enclosures, emergency stop buttons, and safety interlocks to protect operators from potential hazards during the testing process.

When conducting probe wire flexing tests according to EN 61010-031, it is important to follow the specific procedures and requirements outlined in the standard. This includes the number of flexing cycles, the applied force or tension, the test duration, and any other relevant parameters specified.

Input Power

AC220V, 50Hz

Control Method

PLC control, touch screen operation

Station

One

Drive Mode

Electrical

Loading Voltage

0-250V, can be regulated

Load Current

0~32A

Sample judgment

Judge the conduction by current

Socket outlet for sample

Can accept a United Kingdom plug

Test Cycles

0~999999 can be preset

Protractor part

Flexing Test for EN 61010-031:2015 Clause 6.7.4.3

Flexing Angle

±45°, can be preset on the touch screen

Flexing Speed

0-60 cycles/min, can be preset

Test Cycles

0-999999, can be preset

Loading Weight

One set weights, can be used in combination to achieve 2.5N, 5N,10N,18N, 25N, 30N, 40N, 45N

Rotation Test for EN 61010-031:2015 Clause 6.7.4.4

Rotation Angle

0-360°, preset on the touch screen

Rotation Speed

0~20 oscillations/min can be preset