Products

IEC 62368-1 Clause 5.4.1.5.3 Insulation Surface Scratch Resistance Test Apparatus

Products Description

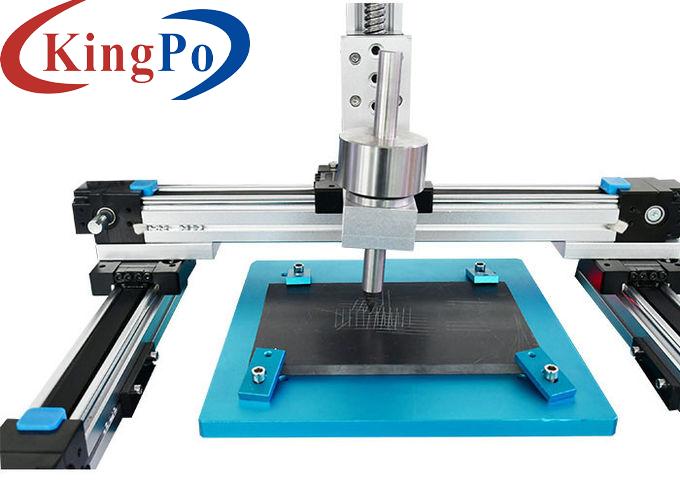

IEC 62368-1 Clause 5.4.1.5.3 Insulation Surface Scratch Resistance Test Apparatus

Production Information:

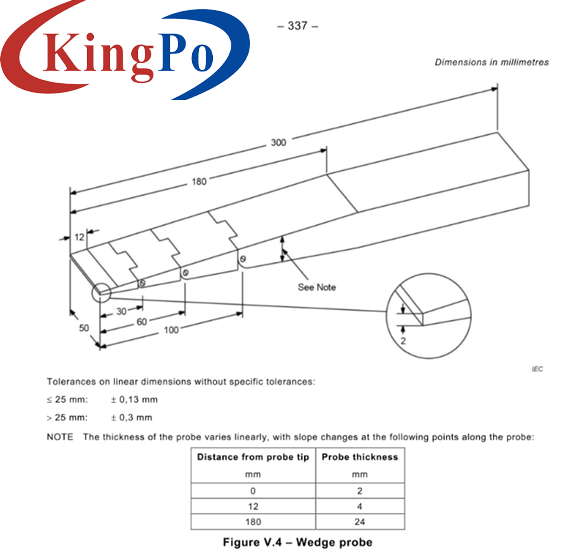

This Insulation Surface Scratch Resistance Test Apparatus meets the requirements of IEC 62368-1 clause 5.4.1.5.3, IEC 60335-2-78:31; IEC 60335-2-95:31; IEC 60335-2-97:31; IEC 60335-2-103:31; IEC 60335-1:21.2; IEC 60335-2-40:31, etc.

It is used to test the solid insulated parts that have been touched, coated with printed boards or coated component of household and similar appliances

Working Principle:

The surface of the insulation is then scratched by means of a hardened steel pin, the end of which has the form of a cone with an angle of 40o. Its tip is rounded with a radius of 0,25 mm ± 0,02 mm. The pin is held at an angle of 80o to 85o to the horizontal and loaded so that the force exerted along its axis is 10 N ± 0,5 N. The scratches are made by drawing the pin along the surface of the insulation at a speed of approximately 20 mm/s. Two parallel scratches are made. They are spaced sufficiently apart so that they are not affected by each other, their length covering approximately 25 % of the length of the insulation. Two similar scratches are made at 90o to the first pair without crossing them.

Technical Parameters:

Applied standard

IEC 62368-1

Applied clause

5.4.1.5.3

Input power supply

AC 220V/50Hz

Test station

1 station

Control method

PLC + touch screen

Drive mode

Stepper motor drive

Scratching speed

0-25mm/s adjustable, can be preset

Scratching times

0-9999 times, it can be preset

Scratching distance

Approximately 25 % of the length of the insulation, can be preset

Test bench

Can be 90o rotated

Scratching pressure

10N±0.5N

Scratching pin

hardened steel pin, the end of which has the form of a cone with an angle of 40o. Its tip is rounded with a radius of 0,25 mm ± 0,02 mm

Scratching angle

80o to 85o to the horizontal