Products

Medical Material Tester ANSI/AAMI-EC53 2013/(R)2020 Flex Life Of Trunk Cable And Patient Leadwire Flex Relief

Products Description

ANSI/AAMI-EC53: 2013/(R)2020 Flex Life Of Trunk Cable And Patient Leadwire Flex Relief

Standard & Clauses:

AAMI-EC53-1998

ANSI/AAMI-EC53:2013/(R)2020 “ECG trunk cables and patient leadwires”

Specimen Range, Application, Principle, Structure and Use Environment:

Samples and Restrictions: EGA trunk cables and patient leadwires

Application: Used to test the bending resistance of EGA trunk cables and patient leadwires when the power cord enters the appliance. To verify its reliable performance.

Principle: Use a motor to drive the fixture to flex the sample. Apply current to the soft wire to make the sample flex left and right at a certain speed and angle of ±90°. And clamp the weight at a position 6 inches away from the lead outlet end of the sample. The test will automatically stop when the equipment reaches the test times or the soft wire is short-circuited.

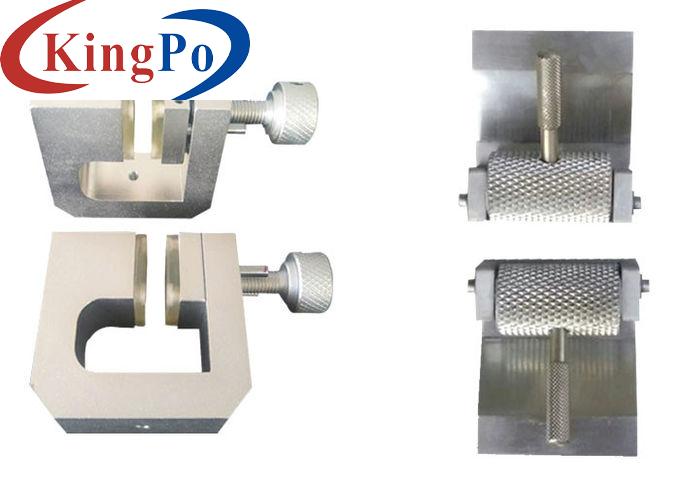

Equipment structure and schematic diagram:

The equipment is driven by a servo motor, and the fixture is installed in the center. And the eccentricity is adjustable. When clamping the sample, the flexing axis and the point where the cord enters the appliance can coincide as much as possible. This results in minimal lateral displacement of the cord and load.

Equipment dimensions: approximately: 800×800×1300 (mm) W×H×D, equipment weight: 130kg

Technical Parameters:

0~999999 Can be preset and set according to standard table 1 requirements

1. 0.23kg (±5%), 1 piece (weight tray).

2. 0.1kg, 10 pieces, (add weight, stack weight). Achieve standard 0.0072*π*d² (±5%)

1. Short circuit judgment

2. Disconnection judgment

Test station

Single

Electrical control method

PLC and 7-inch touch screen

Drive mode

Servo motor drive

Sample clamping method

Mechanical clamping, the position of clamping point is adjustable

Flexing angle

0-360° adjustable arbitrarily (can be preset ±30°, ±45°, ±60°, ±90°)

Flexing rate

0-60 times/min, variable frequency speed regulation

Flexing times

Load weight

Test judgment